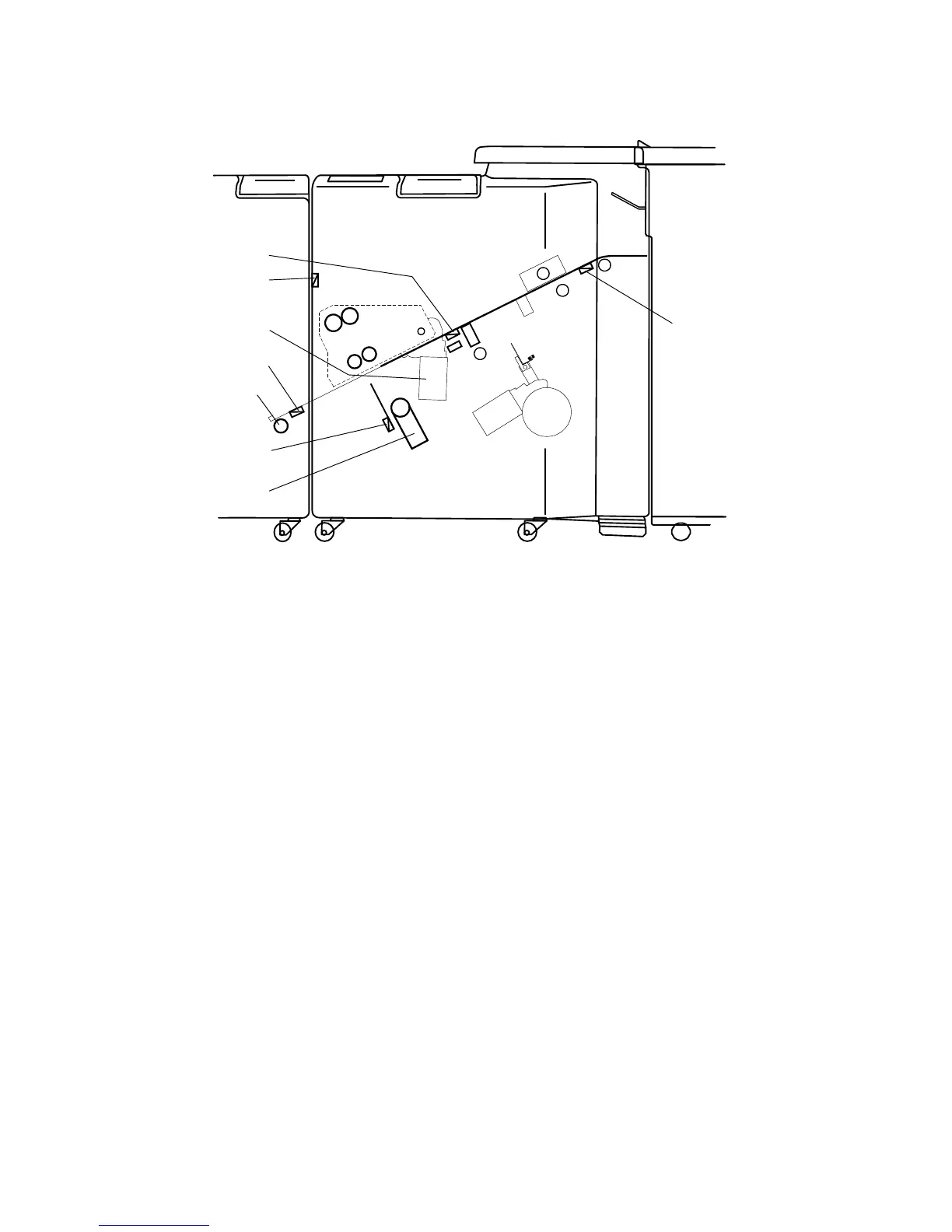

Folding

Folder roller motor (BK-M6) that drives the rst and second pair of fold rollers

starts about the time when the start sensor (BK-Q4) is activated. Also the fold stop

gate motor (BK-M8) moves the fold stop away a bit at that time. Slightly after the

fold stop sensor (BK-Q7) is activated, the fold stop gate motor (BK-M8) jogs the

set upwards into position. Slightly after that the fold knife motor (BK-M7) cycles. The

fold knife pushes the center of the set up through the rst pair of fold rollers. The fold

knife motor will complete its cycle and stop in the lower position when the fold knife

home position sensor (BK-Q15) activates. A booklet is now formed. When the book-

lets leading edge (the spine) is about to enter the second pair of fold rollers, the

fold roller motor (BK-M6) stops for a short time* and then starts again. The time

the booklet sits between the second pair of fold rollers depends on the speed (the

delay between each set) of the copier. The longer it sits the more compressed the

spine becomes, resulting in a atter booklet. When the set is exiting the second

pair of fold rollers the outfeed sensor (BK-Q8) activates. When the trail edge of the

set exits the booklet maker the outfeed sensor (BK-Q8) becomes clear.

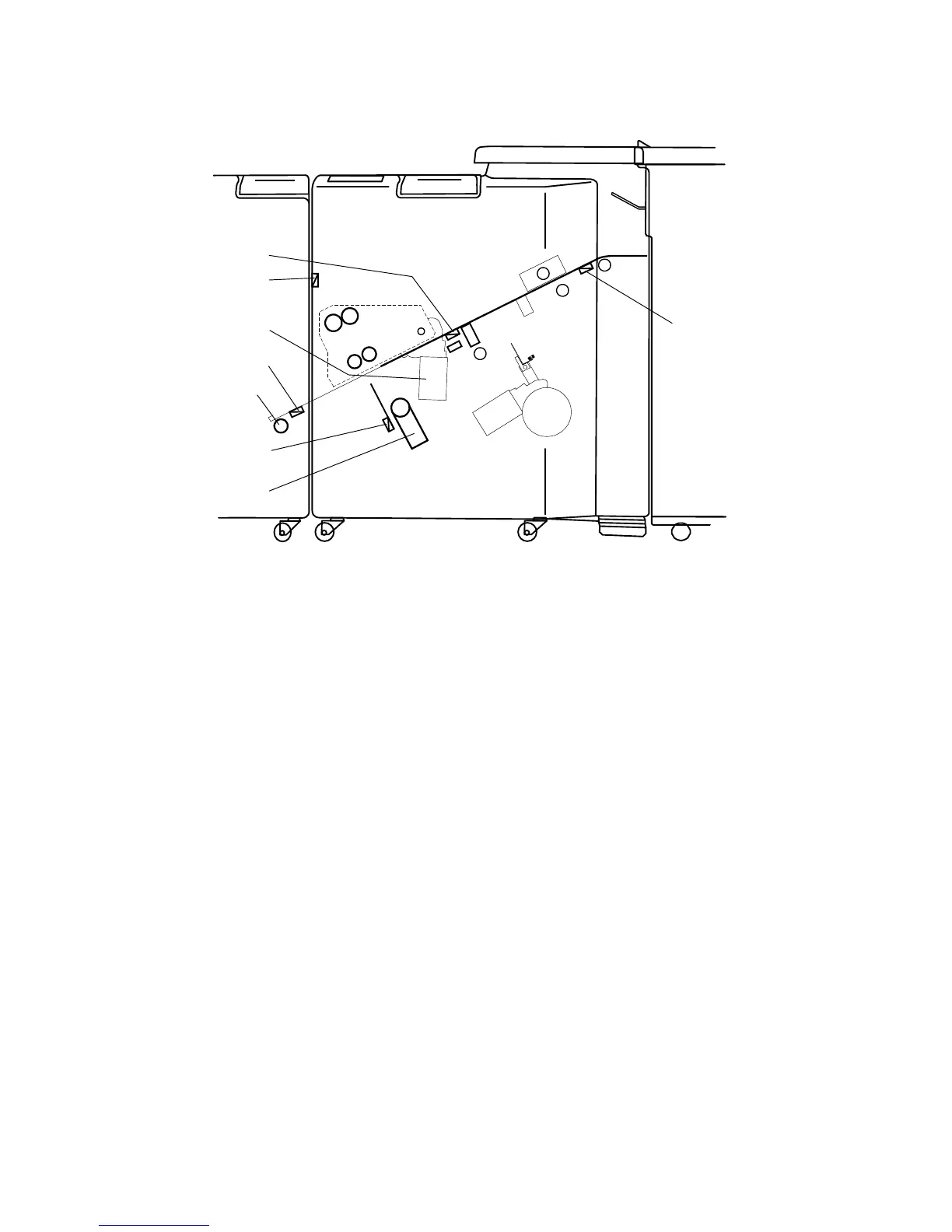

Belt stacker

If the belt stacker is installed directly on the booklet maker (no trimmer installed) the

stacker motor (ST-M1 - not shown in picture) starts when the outfeed sensor (BK-

Q8) activates and runs for a short while to separate the booklets on the stacker belt.

* If fold delay is set to On the booklet sits between the second pair of fold rollers up to

about 15 seconds depending on the interval between sets. If the time interval between

the sets from the Copier is less, the booklet is fed out sooner. When the next booklet

activates the infeed sensor (BK-Q1) the fold roller motor (BK-M6) starts again.

BOOKLET MAKING PROCESS

Loading...

Loading...