32 Rockwell Automation Publication 450L-UM001D-EN-P - December 2019

Chapter 4 Safety Function

Due to vibrations often present in industrial applications, the number of

physically interrupted beams is allowed to be one less than the specified number

of beams. A local adjustment of this tolerance value -1 is not possible with DIP

switches.

If the fixed blanked object only blocked one beam, the tolerance value is zero.

This value means that a minimum of one beam has to be blocked, there is no

tolerance.

The 450L-E safety light curtain can perform fixed blanking of one or more

adjacent beams. Minimum one of the two synchronization beams (Figure 8 on

page 22) must be unblocked before and during the Teach-in procedure.

A teach-in error occurs if one of the cases that are described in Table 4

(see

Figure 11 on page 32

for illustration) happens:

Table 4 - Teach-in Errors and Behavior

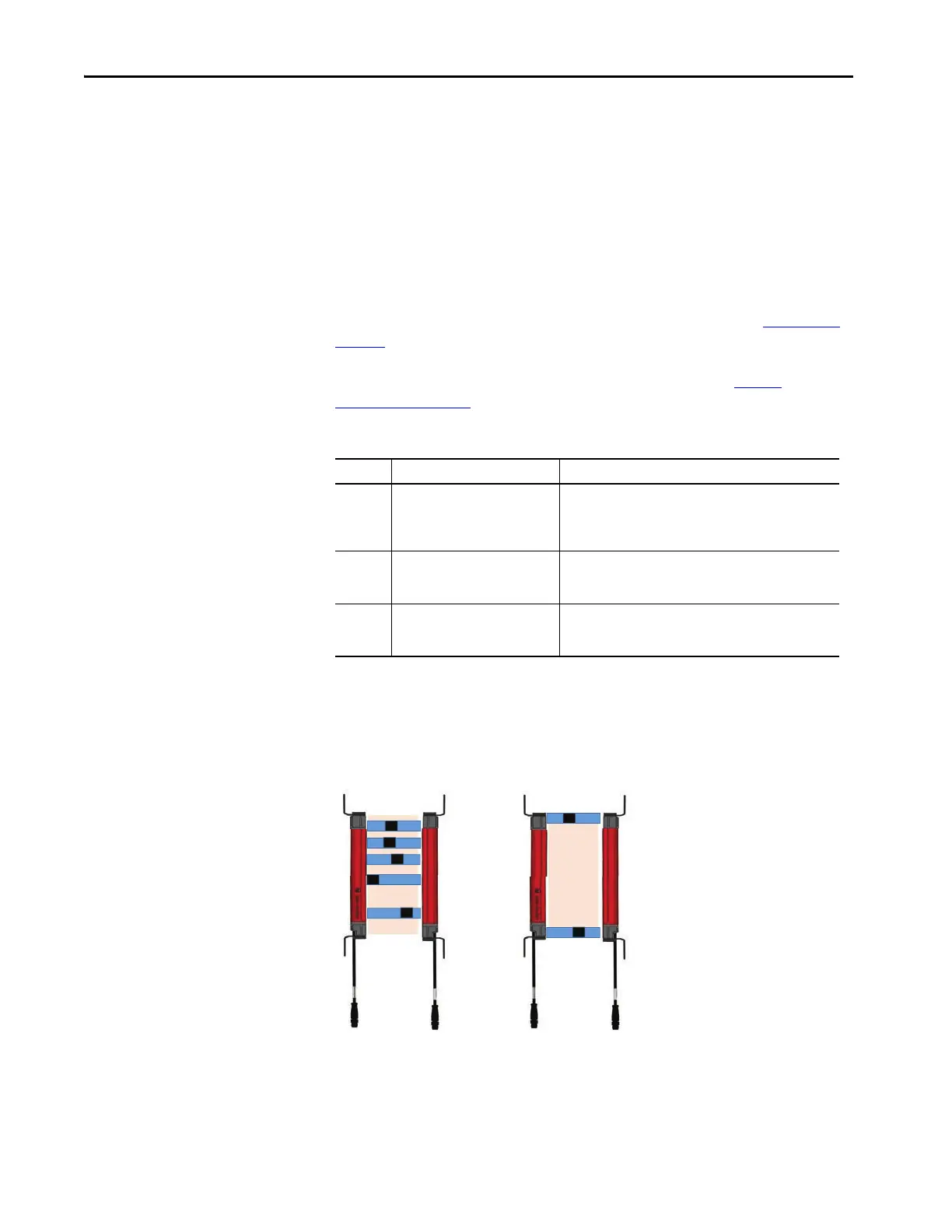

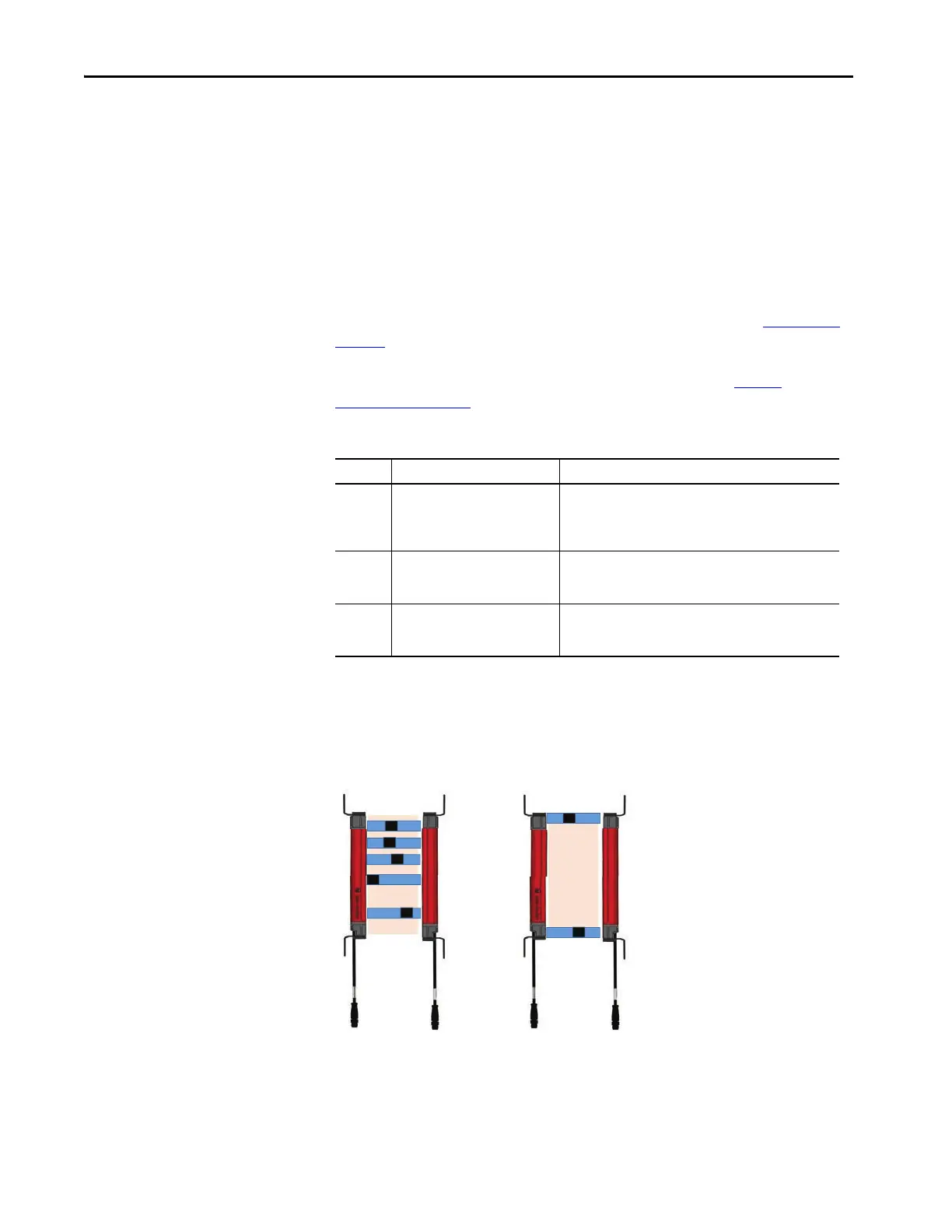

Two set ups that cause teach-in blanking error:

• Case A: Number of objects > 4

• Case B: Top and Bottom end interrupted.

Figure 11 - Teach-in Blanking Error

Case Description Behavior

1

More than four independent objects

are in the protective field

In this case, the first four interrupted objects starting from the

connection plug-in is taught, all other objects are not taught.

As a result, the OSSDs stay in the OFF condition as long as the

additional objects are in the protective field.

2

The beams at top and bottom are

simultaneously blocked

In this case, the teach-in command is ignored and the 450L-E

safety light curtain continues operating with the previously

taught objects.

3

One object was moving during

teach-in

In this case, the teach-in command is completed, but the error

indication at the end of the teach-in process warns the user

that the taught limits can cause sporadic OSSD switching.

AB

Loading...

Loading...