58 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Assembly and Installation

Subject to change without notice

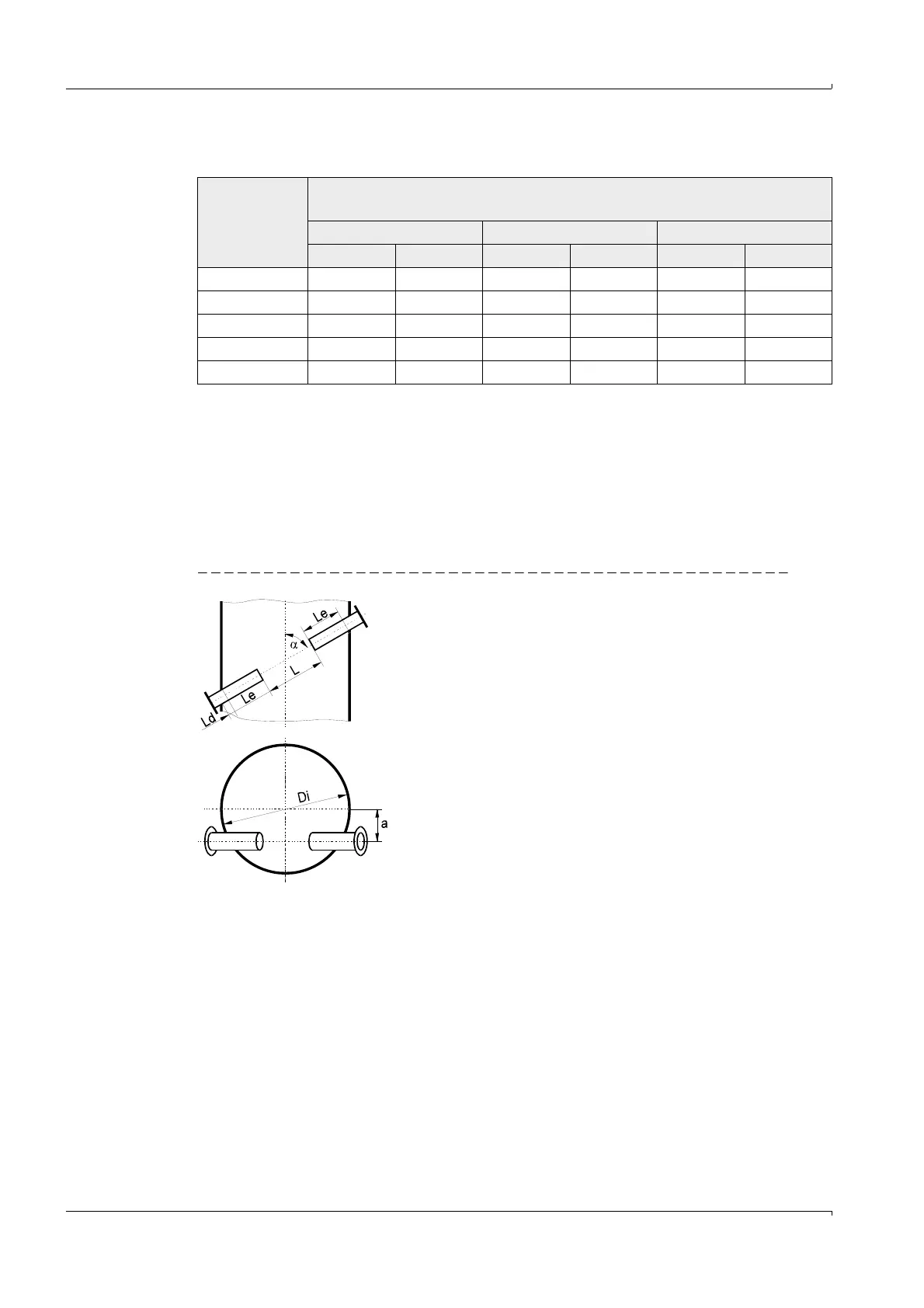

Maximum possible wall (and insulation) thickness as a function of the nominal length of

the flanges with tube, flange size (pipe diameter D

R

) and installation angle (Le = 20 mm):

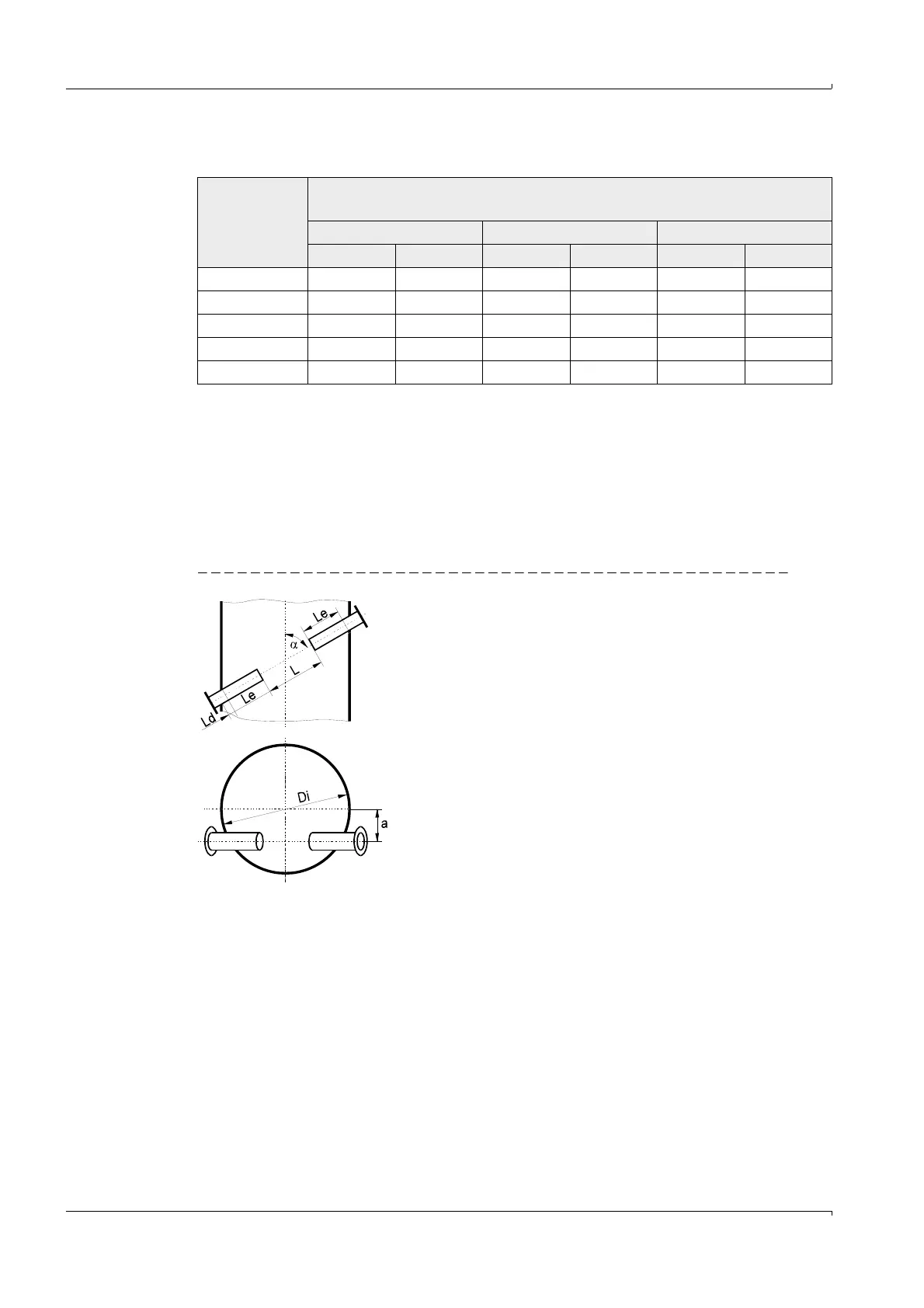

Shortening the measuring path

It may be necessary to shorten the measuring path to prevent problems in signal

transmission in certain cases, e.g. when using types FLSE100H, HAC, PH or PHS with high

dust concentrations (

p. 17, 2.3.1). This can be achieved by installing extended flange

tubes and/or flanges with tube across the secant.

The installation conditions are shown in Fig. 32 and in the following Table.

Fig. 32 Installation across secant

Nominal length

L

F

[mm]

Maximum wall and insulation thickness w [mm]

D

R

= 114.3 D

R

= 76.1 D

R

= 48.3

= 45° = 60° = 45° = 60° = 45° = 60°

125 15 45

200 499768110

350 112 196 155 227 174 240

550 253 369 297 400 315 413

750 395 543 438 573

L = Active measuring path

Le = 20 ... 500 mm

a

max

= Di / 4

a = 60°

Ld as in Fig. 31

With a = a

max

and circular ducts

then (= 60°)

Di

max

= L +2 Le + Ld

Loading...

Loading...