b

Mak

e sure that the safety laser scanner’s field of view is not restricted.

b

Make sure that there are not mirrors or other very reflective objects in the protec‐

tive field.

b

Make sure that no small objects (e.g. cables) are in the protective field, even if the

safety outputs do not switch to the OFF state as a result.

b

Mount the safety laser scanner so that the status indicators are clearly visible.

b

Mount the safety laser scanner so that you can plug in and pull out the system

plug.

b

Take appropriate measures for vibration damping if vibration and shock specifica‐

tions exceed the values and test conditions specified in the data sheet, see "Data

sheet", page 126.

b

For machines that vibrate heavily, use thread-locking compounds to prevent the

possibility of fixing screws coming loose unintentionally.

b

Make sure that the safety laser scanner is aligned correctly, even during mount‐

ing: if the safety laser scanner is intended to monitor an area of 270° on a corner,

the safety laser scanner may be mounted rotated by a maximum of 2.5° about the

vertical axis.

b

Location of the scan plane: see "Dimensional drawings", page 134.

b

Take account of the tightening torque for the fixing screws:

°

M5 at rear/at side = 4.5 Nm … 5.0 Nm

°

M4 at rear/at side = 2.2 Nm … 2.5 Nm

Higher tightening torques may damage the thread. Lower tightening torques do

no

t offer sufficient protection against slipping of the safety laser scanner due to

vibrations, for example.

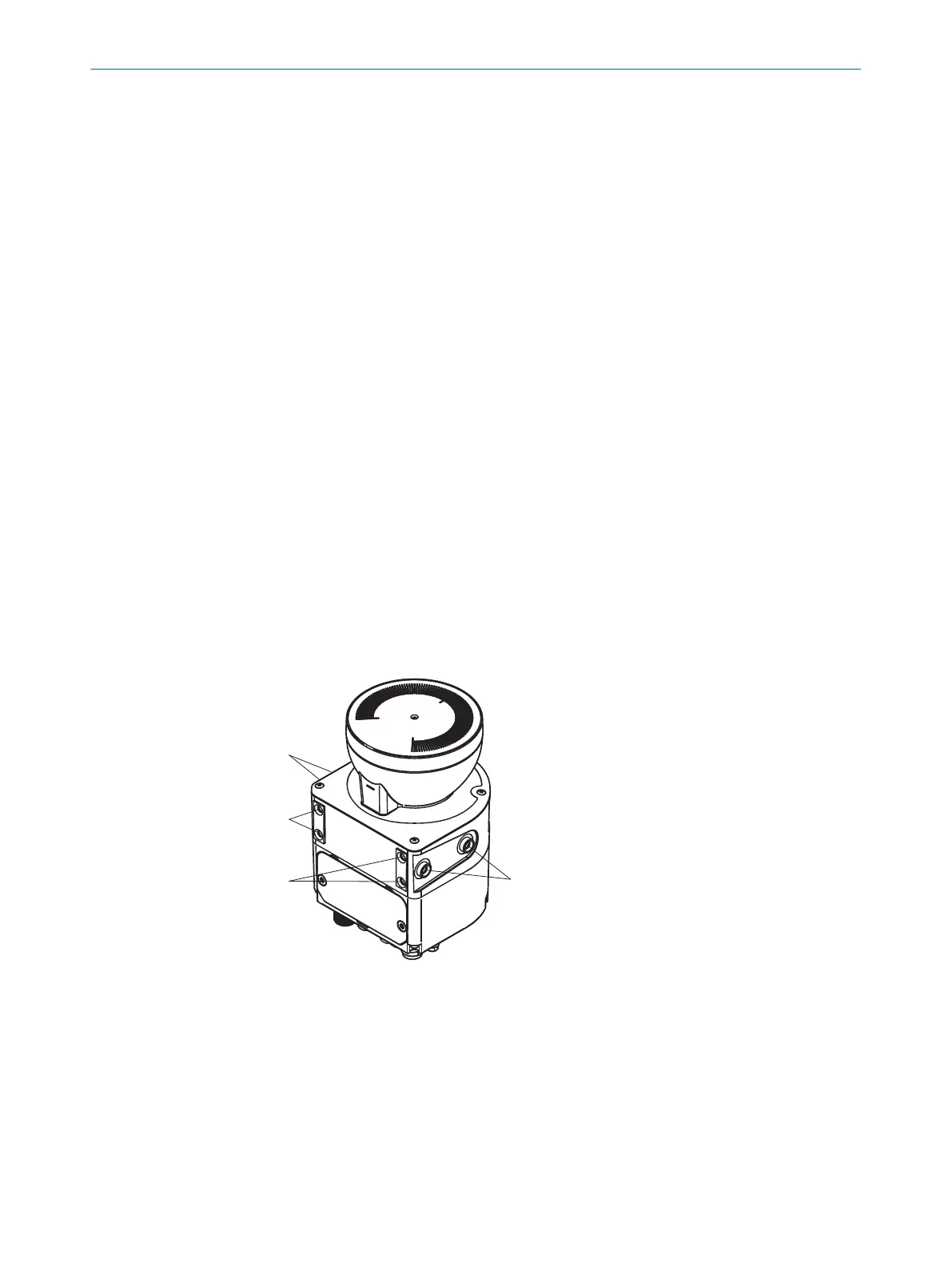

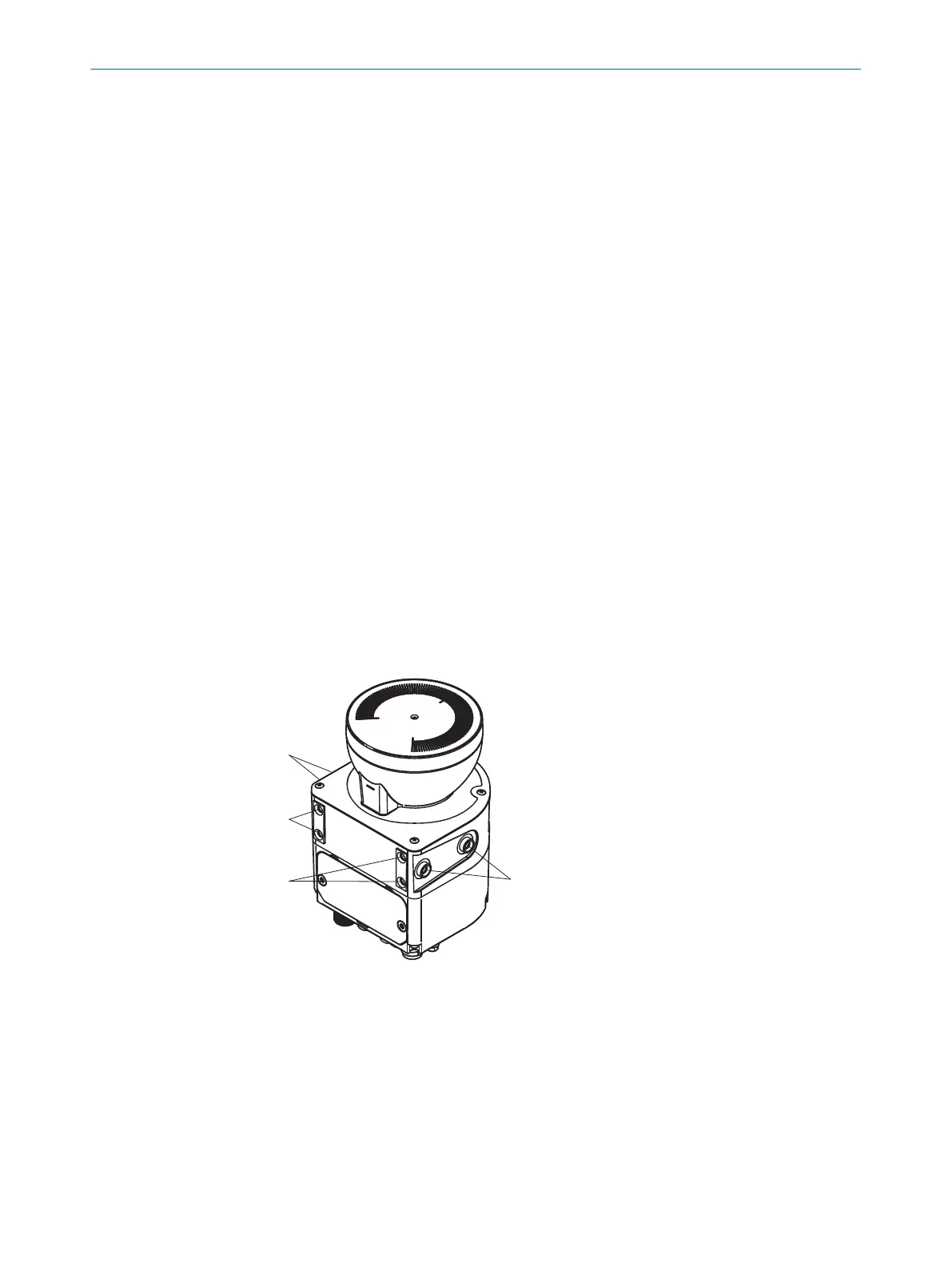

5.3.1 Direct mounting

The safety laser scanner has 4 M5 threaded holes on the back. If you are able to drill

through the mounting surface from the rear, you can mount the safety laser scanner

directly using these threaded holes.

Figure 39: Mounting the safety laser scanner directly

1

Rear M5 threaded hole

2

Side M5 threaded hole

b

Use eit

her the rear or the side M5 threaded holes for direct mounting, see

figure 39, page 58.

b

Use all four rear or all 4 side M5 threaded holes for direct mounting, so that the

values given in the data sheet for vibration and shock resistance are achieved.

b

Maximum depth of thread engagement: 7.5 mm (see "Dimensional drawings",

page 134).

b

Tightening torque: 4.5 Nm to 5.0 Nm.

5 MOUN

TING

58

O P E R A T I N G I N S T R U C T I O N S | microScan3 Core I/O AIDA 8017784/1ELL/2022-01-21 | SICK

Subject to change without notice

Loading...

Loading...