9.8 Configuring SINAMICS S120 with 802D sl

Commissioning

9-98

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

Note

For the meanings of the contents of the individual warning codes and warning values,

please refer to the Manual /DG/ SINUMERIK 802D sl “Diagnostics Guide”, Chapter

“Sinamics Alarms”.

9.8.4 Setpoint/actual-value assignment

The axis machine data MD 30130: CTRLOUT_TYPE can be used to switch the setpoint out-

put, and MD 30240: ENC_TYPE can be used to switch the actual-value input between simu-

lation and PROFIBUS drive.

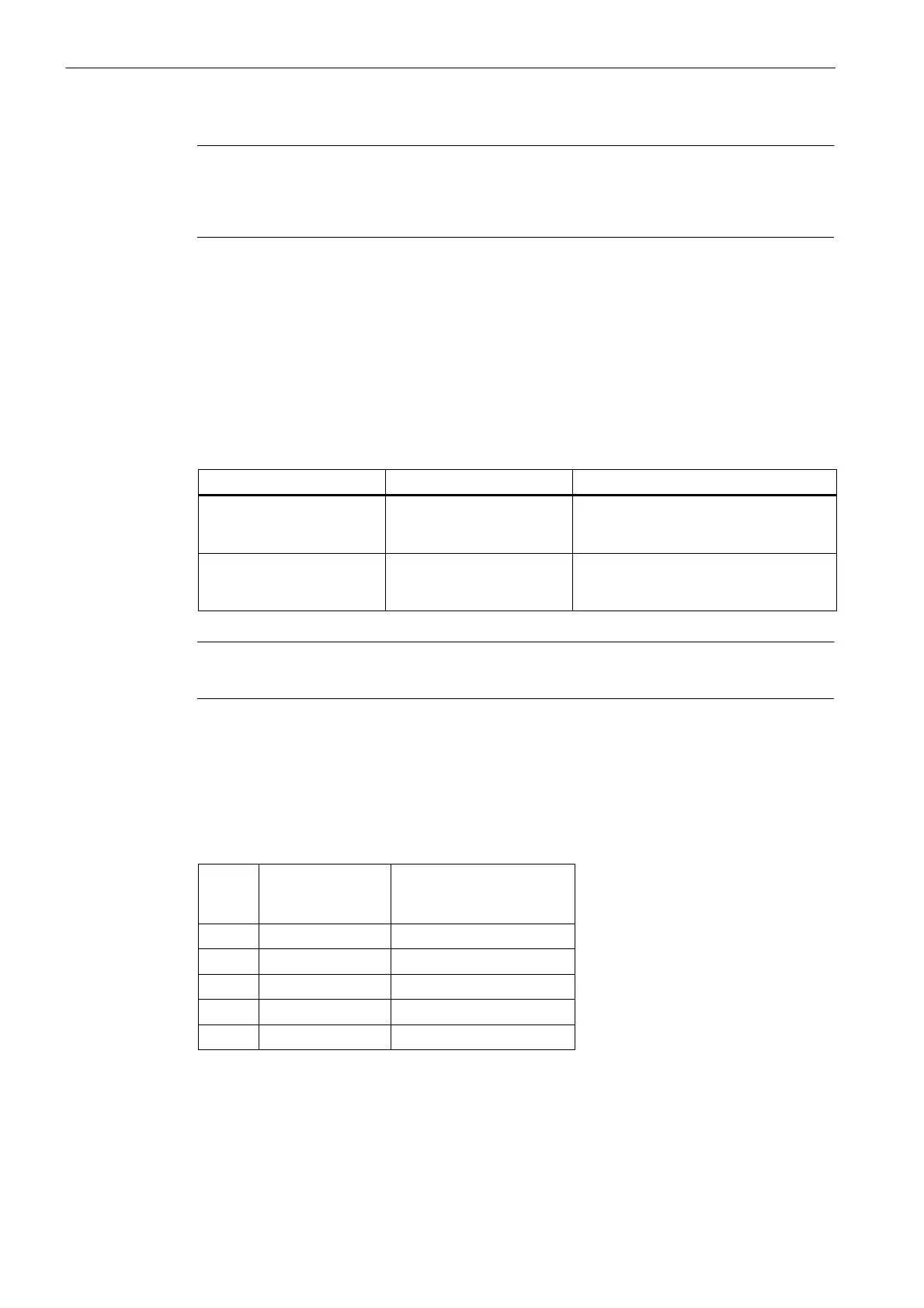

Table 9-7

Machine data

Simulation Normal mode

MD 30130 Value = 0

Simulation

Value = 1

In this case, the setpoint signals are output via

Profibus.

MD 30240 Value = 0

Simulation

Value = 1 (INCR) or 4 (EnDat)

In this case, the actual values are read in via

Profibus.

Note

For simulation, MD 30130 and MD 30240 must be parameterized with “0”.

To enable the relevant NC axis to assign its setpoint to the appropriate SINAMICS drive, en-

suring that the actual values are returned from this SINAMICS drive, it is imperative to para-

meterize the machine data MD 30110: CTRLOUT_MODULE_NR and MD 30220: ENC_MO-

DULE_NR.

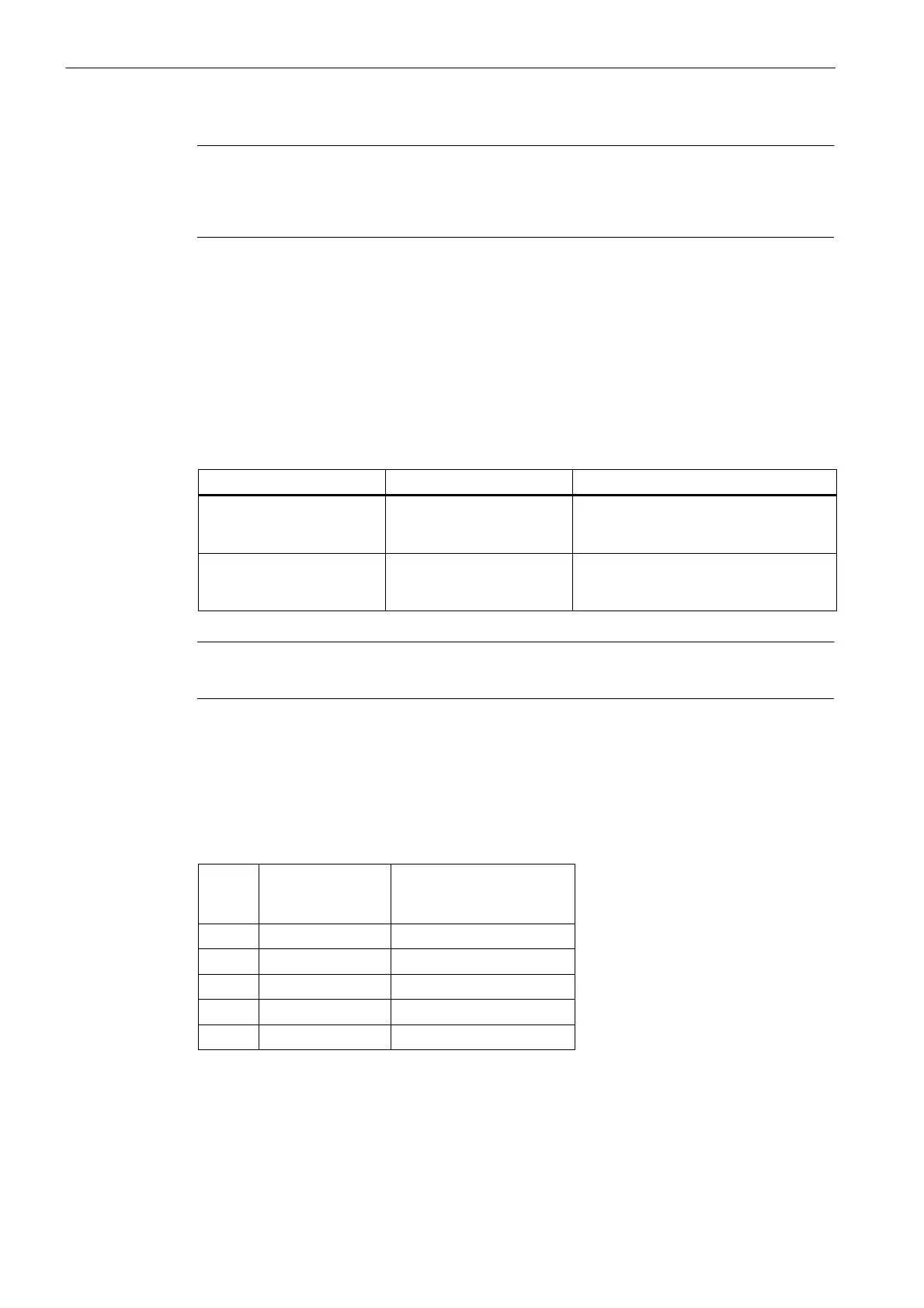

The following applies for the maximum configuration of 5 axes with Active Line Module:

Axis Drive number

MD 30110

MD 30220

SINAMICS object no.

X1 2 3

Y1 3 4

Z1 4 5

SP 1 2

A1 5 6

If this setting does not match the order in the drive group (the order of the drive CliQ connec-

tions corresponds to the order of the SINAMICS object no., here: 1. ALM, 2. Spindle,

3. X1 axis, 4. Y1- axis, 5. Z1 axis, 6. A1 axis), the data must be adapted accordingly.

Loading...

Loading...