9.8 Configuring SINAMICS S120 with 802D sl

Commissioning

9-100

SINUMERIK 802D sl Instruction Manual (BA), 05/2005 Edition

6FC5 397-0CP10-1BA0

Note

For feed axes, only parameter set 1 = index [0] is used. Index [1] ... [5] must only be

parameterized when using the “Switch set of parameters” function (see /FB/ Chapter 3),

G331 “Rigid tapping” or G33 (see /FB/ Chapter 11). In this section, the values must only be

entered in index [0].

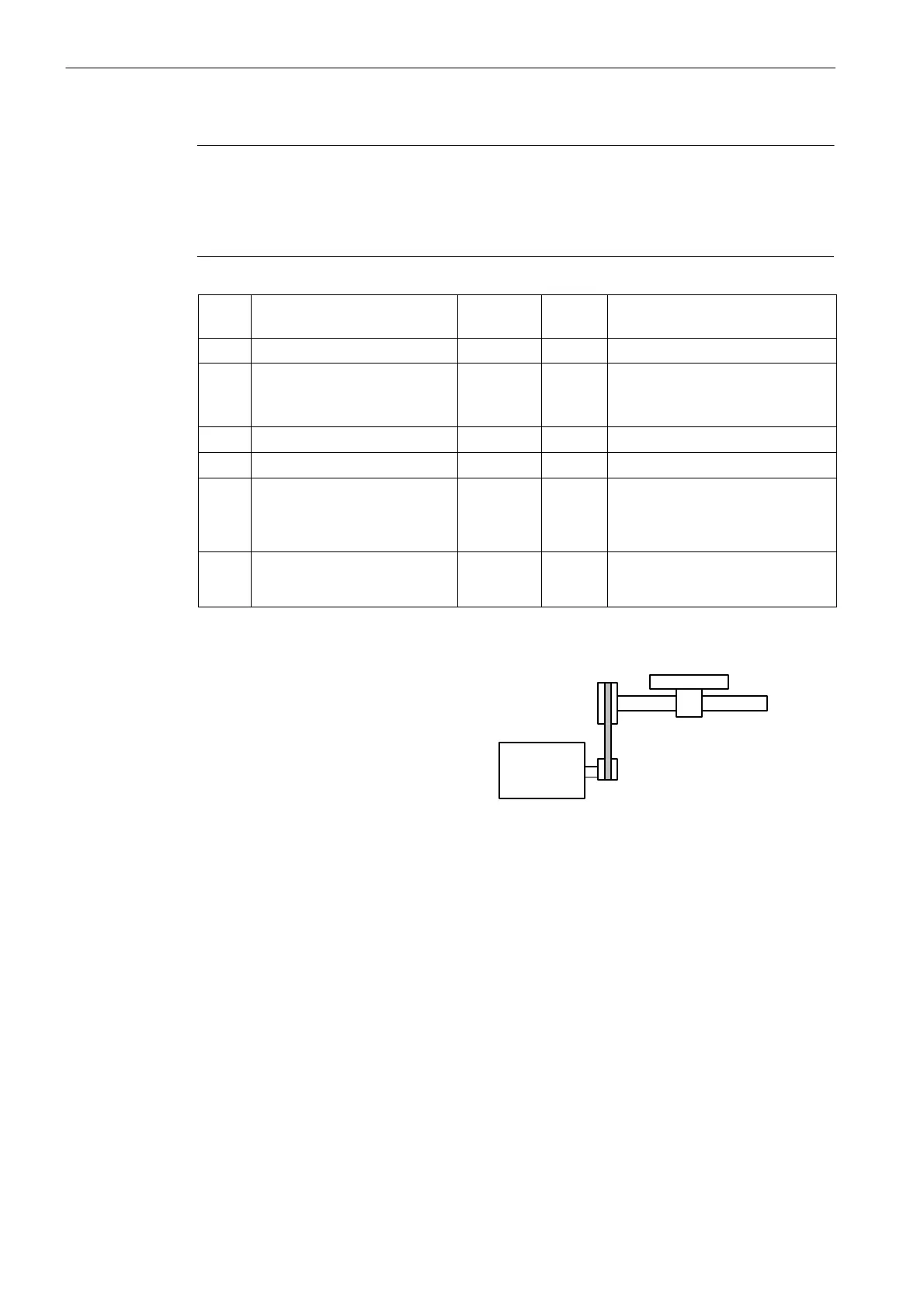

MD Name Default

value

Unit Remark

31030 LEADSCREW_PITCH 10 mm Leadscrew of the ballscrew

31050

31060

DRIVE_AX_RATIO_DENOM

DRIVE_AX_RATIO_NUMERA

1

1

Load gear transmission ratio

Revolutions of the ballscrew

Motor revolutions

32000 MAX_AX_VELO 10000 mm/min Maximum axis velocity

32300 MAX_AX_ACCEL 1 m/s

2

Maximum axis acceleration

34200 ENC_REFP_MODE 1 1: Incremental encoder

Motor order no: 1Fx6xxx-xxxxx-xAxx

0: EnDat encoder

Motor order no: 1Fx6xxx-xxxxx-xExx

36200 AX_VELO_LIMIT 11500 mm/min Threshold value for velocity monitoring;

setting rule:

MD 36200 = 1.15 x MD 32000

Example:

Motor with incremental encoder

Gearbox transmission ratio: 1:2

Spindle lead 5 mm

Max. axis velocity 12 m/min

Max. axis acceleration 1.5 m/s

2

Machine data settings:

MD 31030 = 5

MD 31050 = 1

MD 31060 = 2

MD 32000 = 12000

MD 32300 = 1.5

MD 36200 = 13800

The axis can now be traversed. The direction of movement can be reversed using

MD 32100: AX_MOTION_DIR = 1 or –1 (without influencing the control direction of the

position control).

Loading...

Loading...