Programming

10.1 Fundamental principles of NC programming

Surface grinding

Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

199

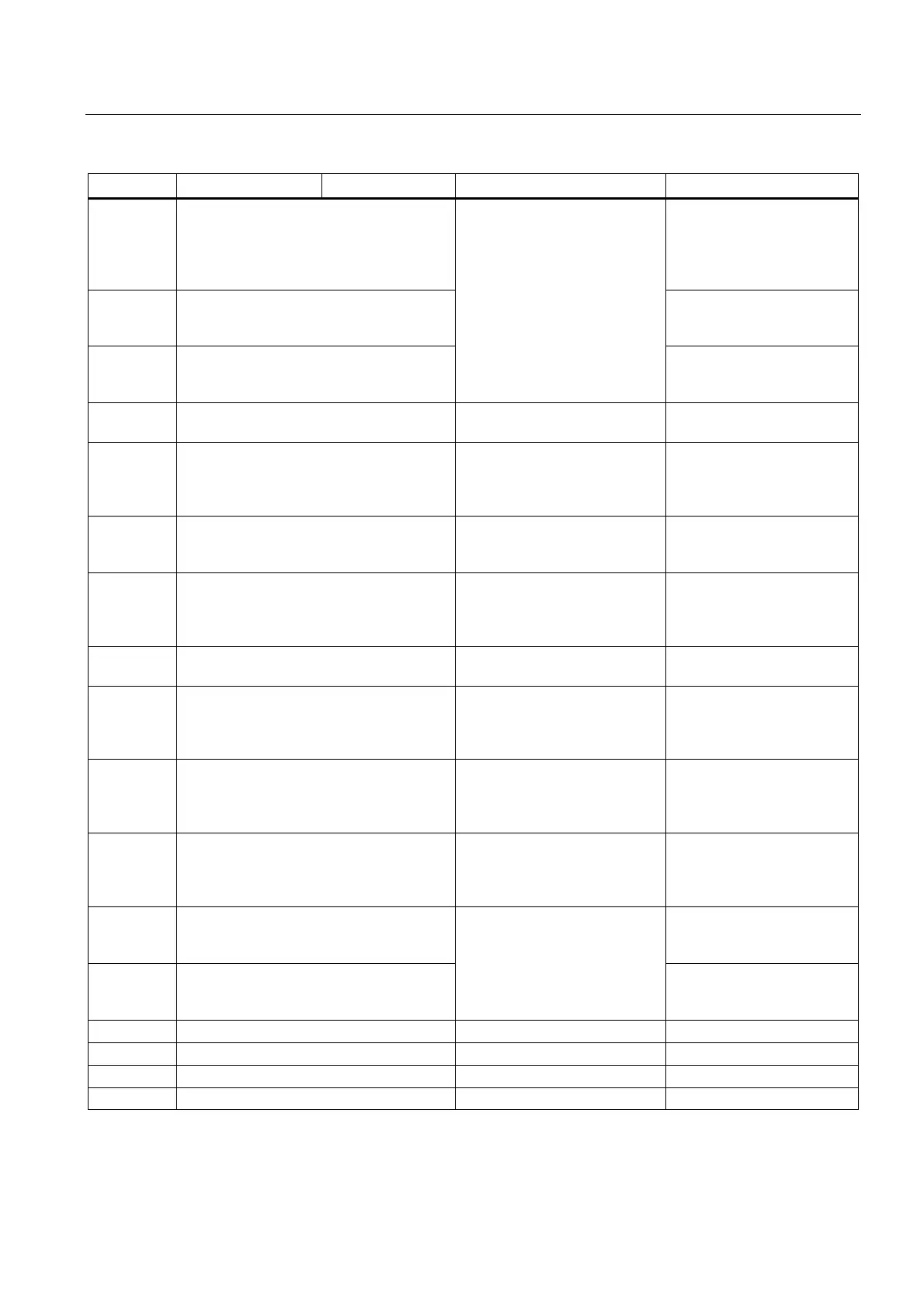

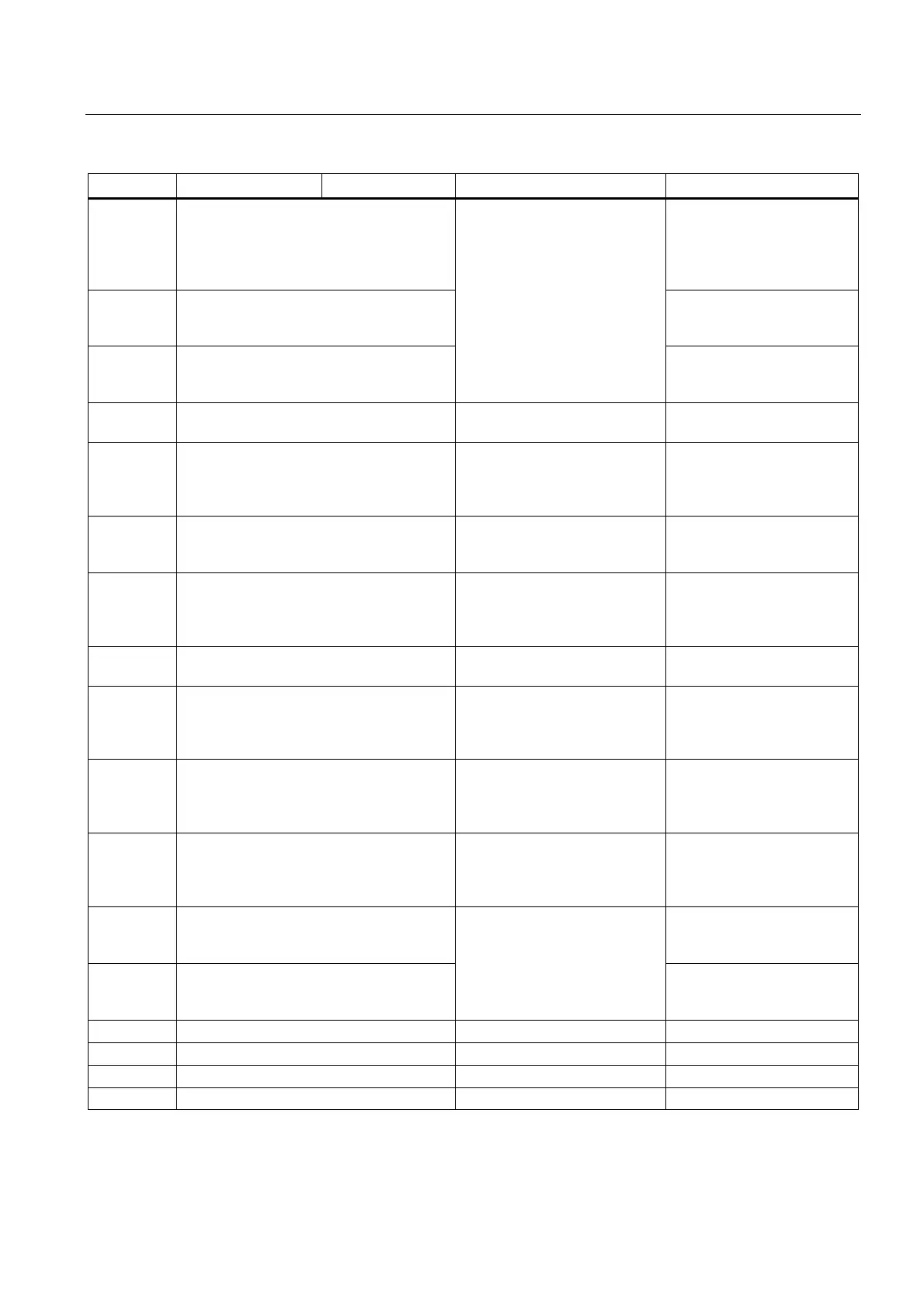

Address Meaning Value assignments Information Programming

G4 Dwell time G4 F...;separate block, F:

Time in seconds

or

G4 S.... ;separate block, S: in

spindle revolutions

G74 Reference point approach G74 X1=0 Z1=0 ;separate

block,

(machine axis identifier!)

G75 Fixed point approach

2: Special motions, dwell time

non-modal

G75 X1=0 Z1=0 ;separate

block,

(machine axis identifier!)

TRANS translation, programmable 3: Write memory TRANS X... Z... ;separate

block

SCALE Programmable scaling factor non-modal SCALE X... Z... ; scaling

factor in the direction

of the specified axis,

separate block

ROT rotation, programmable ROT RPL=... ;rotation in the

current plane

G17 to G19, separate block

MIRROR Programmable mirroring MIRROR X0 ; coordinate

axis whose

direction is changed,

separate block

ATRANS additive translation, programming ATRANS X... Z... ; separate

block

ASCALE Additive programmable scaling factor ASCALE X... Z... ; scaling

factor in the direction

of the specified axis,

separate block

AROT additive programmable rotation AROT RPL=... ; rotation in

the current plane

G17 to G19,

separate block

AMIRROR additive programmable mirroring AMIRROR X0 ; coordinate

axis whose

direction is changed,

separate block

G25 Lower spindle speed limitation

or

lower working area limitation

G25 S... ;separate block

G25 X... Z... ;separate block

G26 Upper spindle speed limitation

or

upper working area limitation

G26 S... ; separate block

G26 X... Z... ; separate block

G17 X/Y plane 6: Plane selection

G18 * Z/X plane

G19 Y/Z plane

G40 * Tool radius compensation OFF 7: Tool radius compensation

Loading...

Loading...