Appendix

A.2 Parameter tables of the tool data

Surface grinding

Programming and Operating Manual, 11/2012, 6FC5398-5CP10-3BA0

345

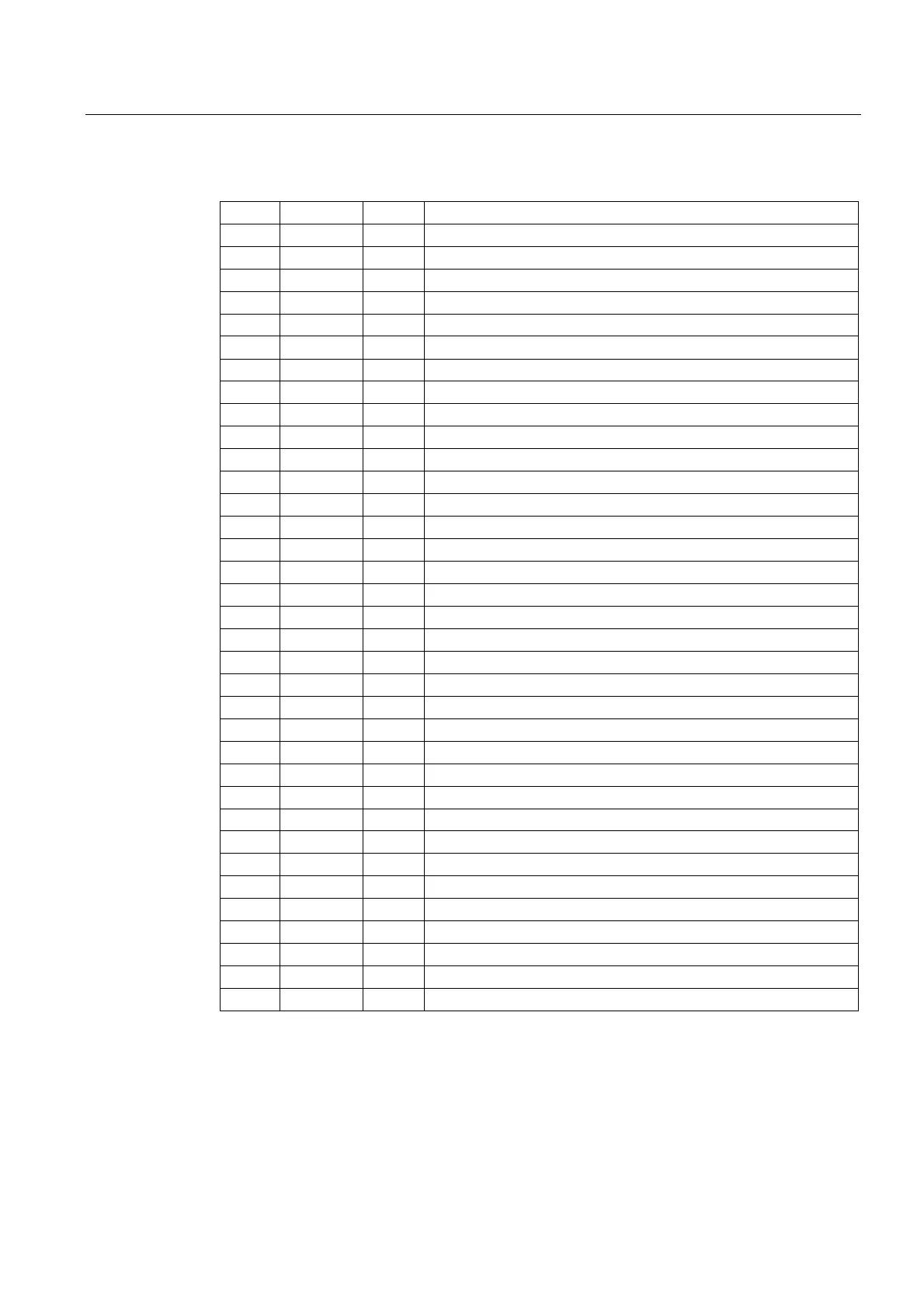

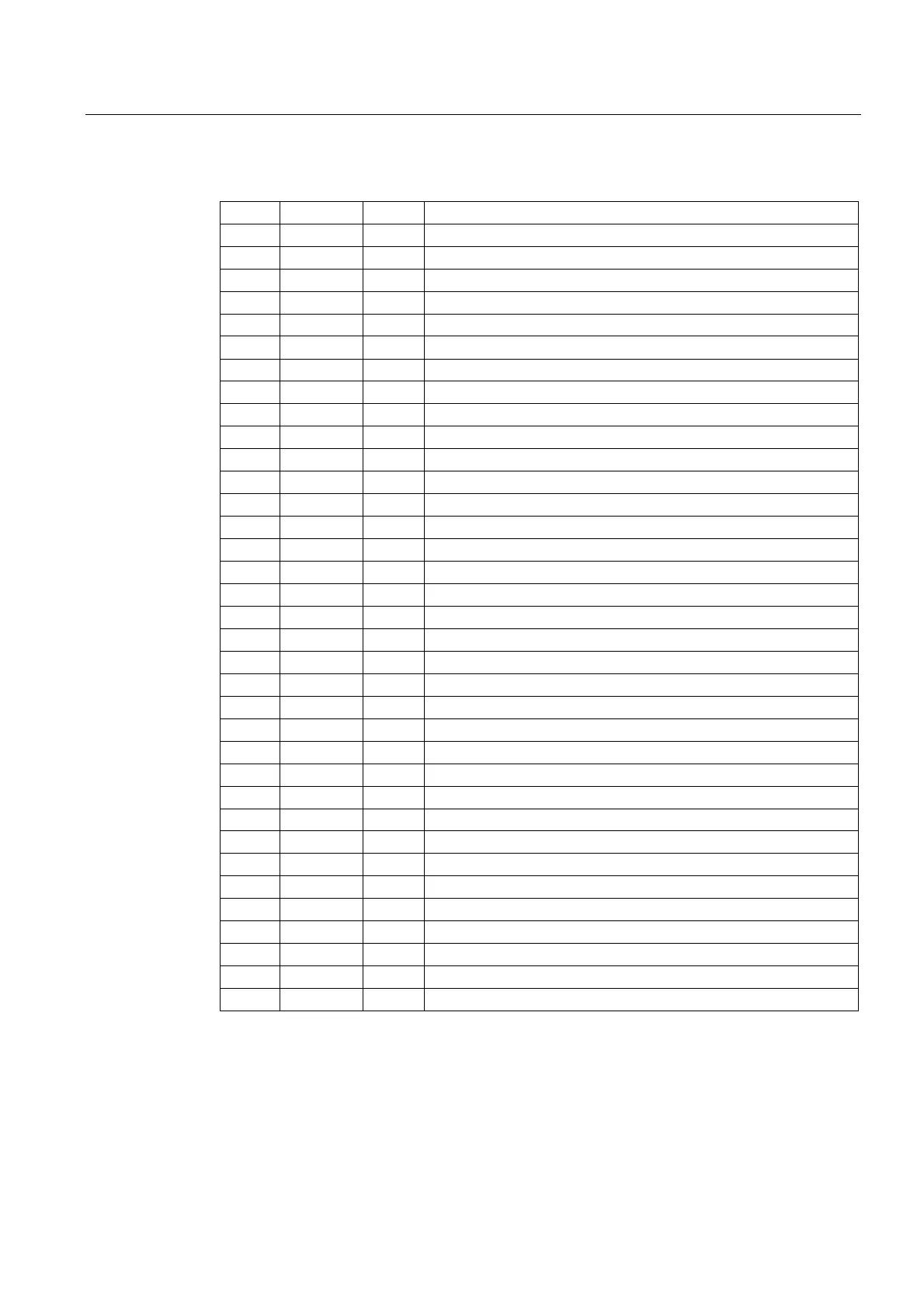

Table A- 5 7. to 9th cutting edge for dressers

Tx Dy DP1 INT Tool type=403

Tx Dy DP2 INT Cutting edge position (1...9)

Tx Dy DP3 REAL Position

Tx Dy DP4 REAL Position

Tx Dy DP5 REAL Position

Tx Dy DP6 REAL R - Tool nose radius

Tx Dy DP7 REAL Diameter

Tx Dy DP8 REAL Width

Tx Dy DP9 REAL Maximum peripheral speed

Tx Dy DP10 REAL Maximum speed

Tx Dy DP11 REAL Probing data block

Tx Dy DP12 REAL dD - Change in diameter (dressing amount X)

Tx Dy DP13 REAL dL - Change in distance (dressing amount Z)

Tx Dy DP14 REAL (Length 3)

Tx Dy DP15 REAL dR - Change in tool nose radius (radius wear)

Tx Dy DP16 REAL Roller circumference speed

Tx Dy DP17 REAL Maximum length 1 wear

Tx Dy DP18 REAL Maximum length 2 wear

Tx Dy DP19 REAL Maximum length 3 wear

Tx Dy DP20 REAL Roller direction of rotation optional

Tx Dy DP21 REAL Additional compens. in X, diameter, basic dimension

Tx Dy DP22 REAL Additional compens. in Z, length in Z, basic dimension

Tx Dy DP23 REAL (reserved, length 3)

Tx Dy DP24 REAL Z oscillating path

Tx Dy DP25 REAL Infeed amount per stroke

Tx Dy DPC1 REAL Reciprocation speed

Tx Dy DPC2 REAL Dressing amount

Tx Dy DPC3 REAL Approaching distance

Tx Dy DPC4 REAL X start

Tx Dy DPC5 REAL Z start

Tx Dy DPC6 REAL Dresser type (0 – X/Z, >0 rear, rotating,...)

Tx Dy DPC7 REAL Profile depth

Tx Dy DPC8 REAL Safety speed

Tx Dy DPC9 REAL X oscillating path

Tx Dy DPC10 REAL Reserved

Loading...

Loading...