103

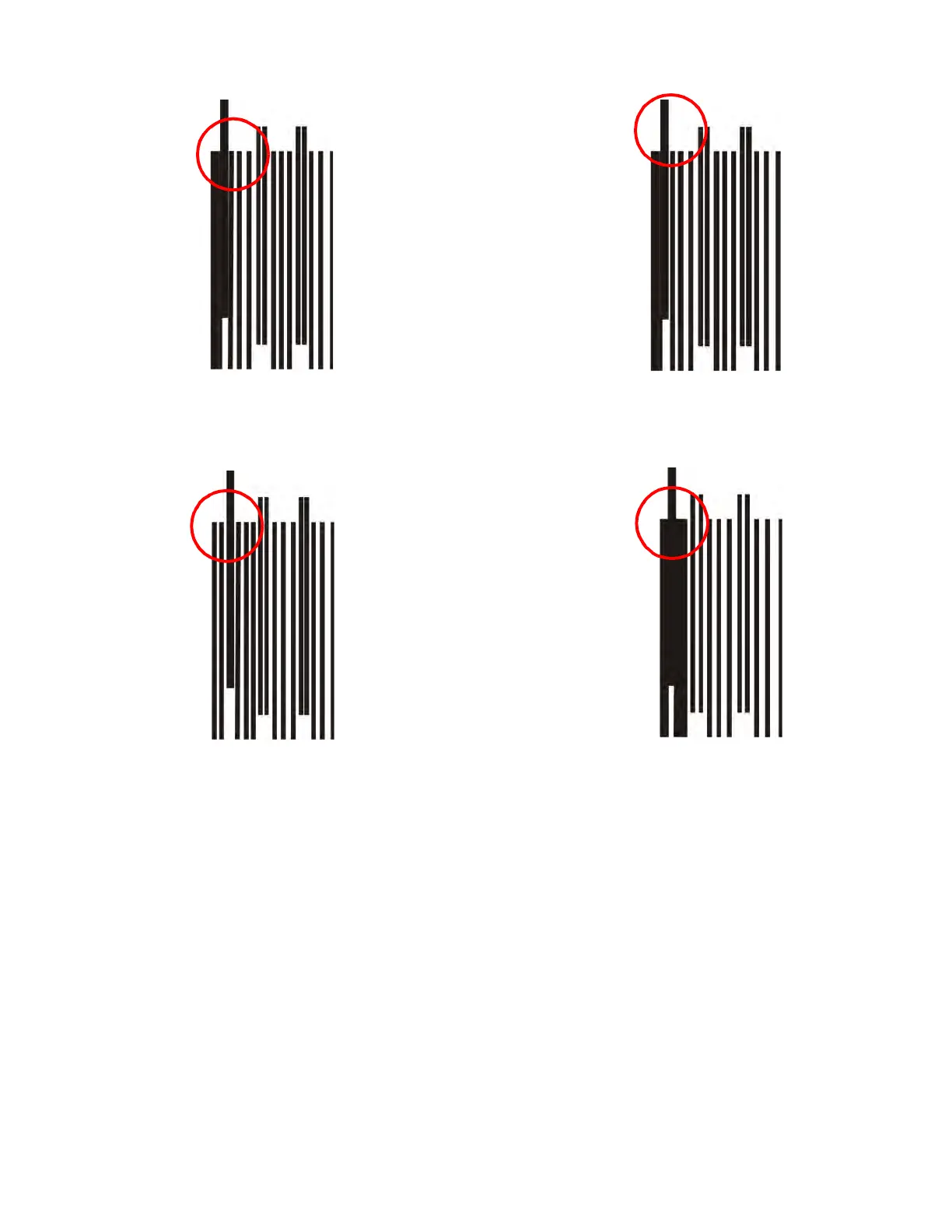

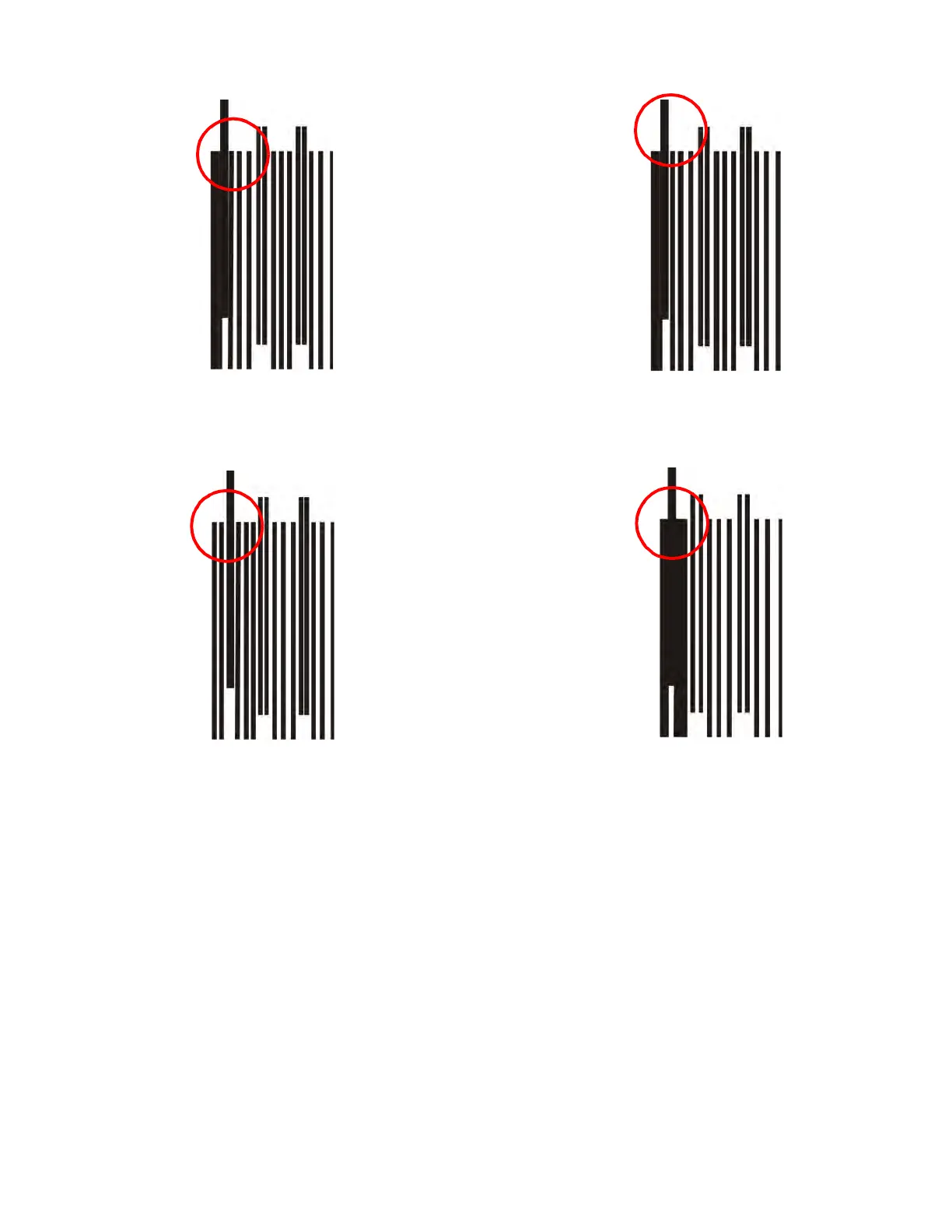

Figure 5-2: Z Zero Calibration Inspection

2. If examination of the Z zero verniers indicate Z zero is set either too high (tip too far away from

platen) or too low (tip too close to platen), adjust the Z zero setting using the up arrow or down

arrow. Use small increments such as ± .004 (0.1016 mm). After making the adjustment, build a

Z_Zero_Vernier to verify change.

Acceptable - The first open gap is

visible between the reference

toolpaths and the first calibration

toolpath.

Target - The first open gap

is visible between the first and

second calibration toolpath.

Out of Target - The first open gap

visible between the first and second

Out of Target - The first open gap

is visible between the second and

third calibration toolpaths. This

indicates that Z Zero has been

calibrated too low.

calibration toolpaths before the reference

toolpaths. This indicates that Z Zero has

been calibrated too high.

Loading...

Loading...