106

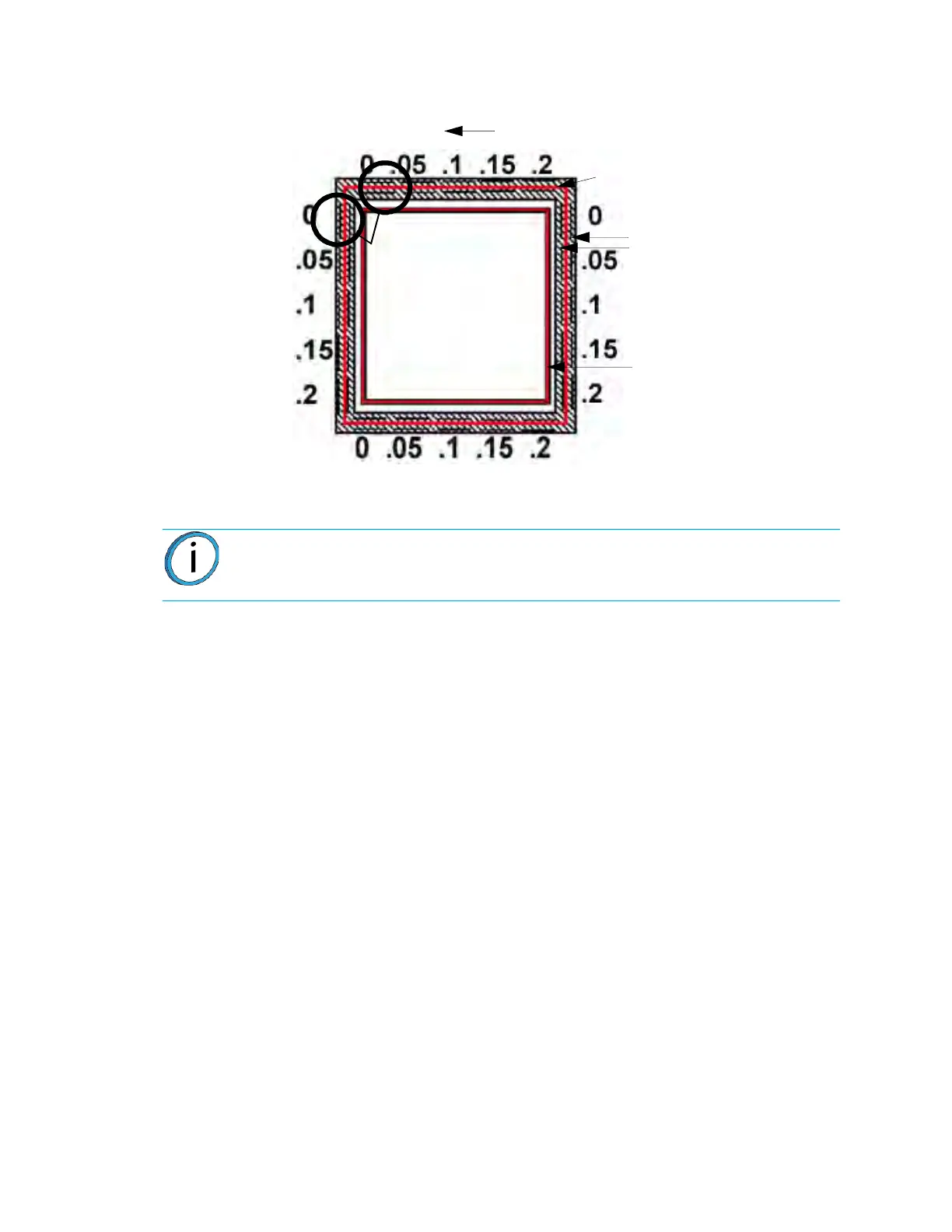

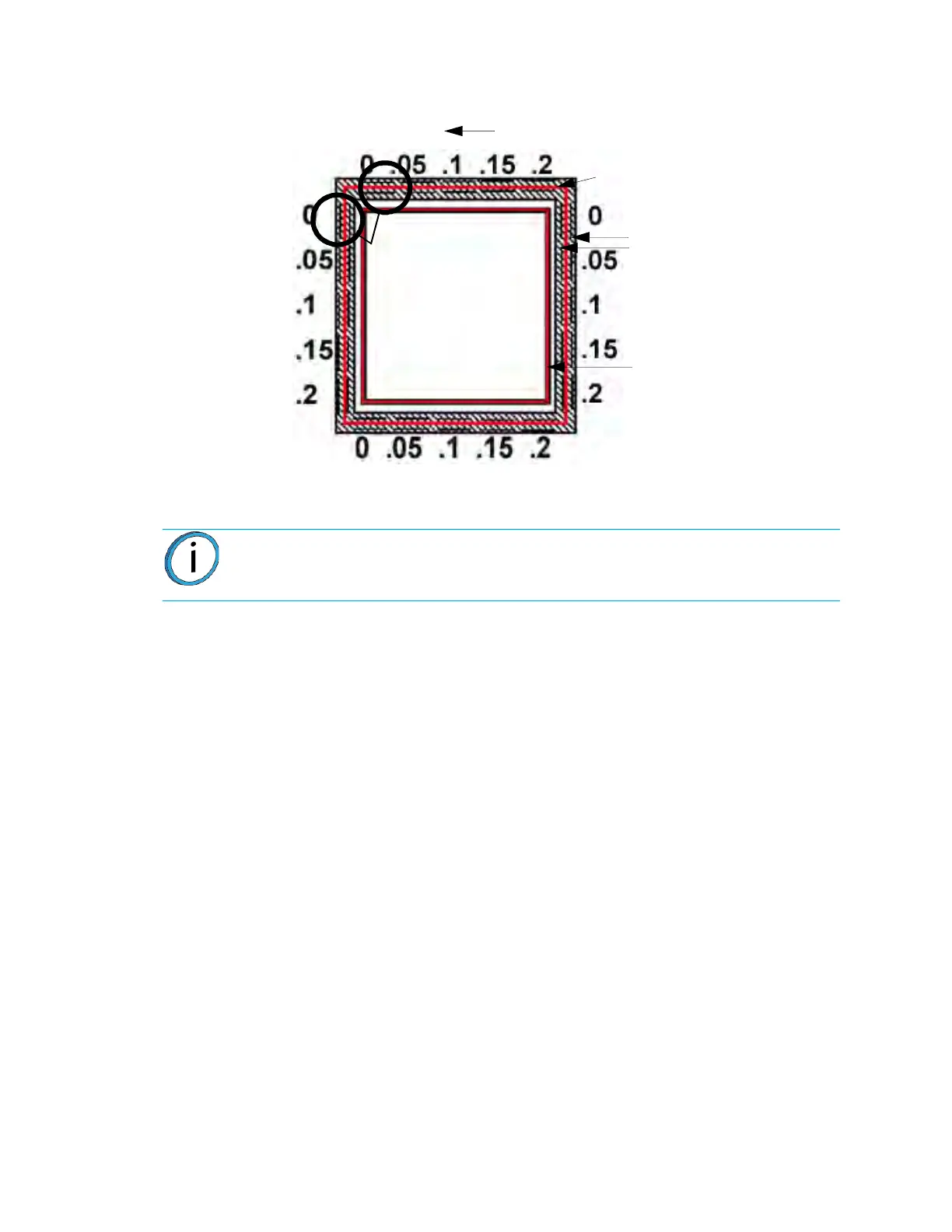

Figure 5-5: Calibration Model - Metric Units

4. Determine the Z Adjustment.

A

. Peel the Support layer from the Z Calibration box.

B

. Measure the thickness of the Support layer with a caliper or micrometer.

•

If the measured value is within ±0.0005 inch (0.01 mm) of Model Tip slice height,

n

o adjustment is necessary.

• Enter the value that is read from the caliber in the “Support Thickness” field.

C

. If an adjustment entry is required, re-run the calibration model on a clean

b

uild sheet.

D. Continue to check for Z Calibration until the Support layer matches the Model

T

ip slice height ±0.0005 inch (0.01 mm).

ADJUST XYZ CALIBRATION OFFSETS FOR CONTROLLER

SOFTWARE VERSION 3.31 AND LATER

Software controller version 3.31 and later creates a calibration box where each axis has its own

line containing both plus and minus values. This eliminates any confusion caused by the

calibration box having two identical axis lines.

The calibration process is performed as it was previously performed. The calibration box is

re

moved from the machine and a magnifying glass is used to verify where the support toolpath is

centered on each axis. Each marker is equivalent to .002 (.05mm). The GUI is used to align the

arrow indicators as they appear on the calibration box. If the support toolpath is centered on the

X or Y markers, the tips are properly calibrated. The Z toolpath is measured the same as the

other calibration jobs.

Note: Do not measure for Z adjustment until the Calibration Model shows the XY

Offset to be less than 0.002 inch (0.05 mm) for the X and Y axis.

Tip Offset Adjustment Indicators

X - Y Support

Calibration Toolpath

X - Y Alignment

Indicators

Z Calibration Box

- Y

+ Y

+ X

Example: Best

Centered Position

This example requires

an adjustment to

Y of -.05 mm. The X axis

requires no adjustment.

- X

Loading...

Loading...