141

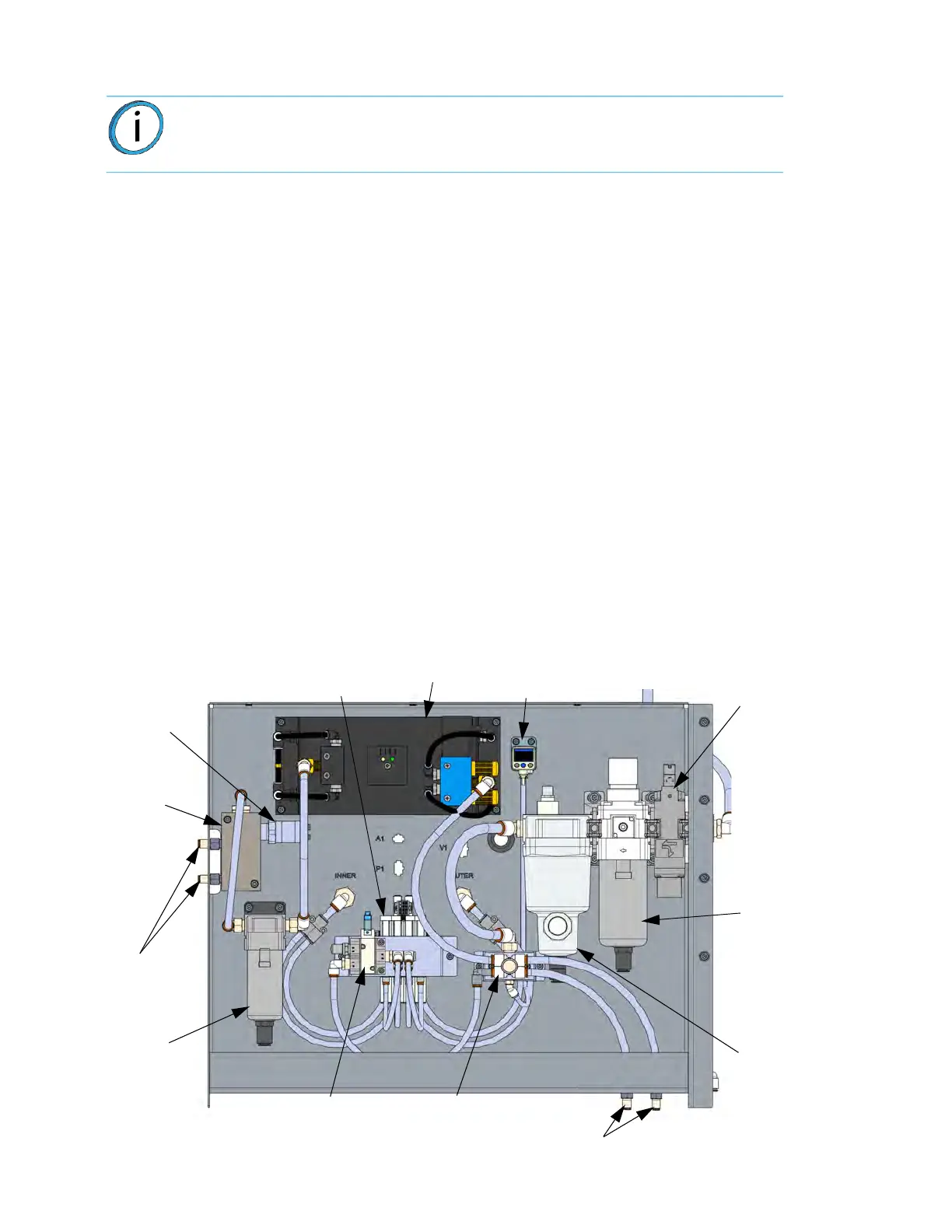

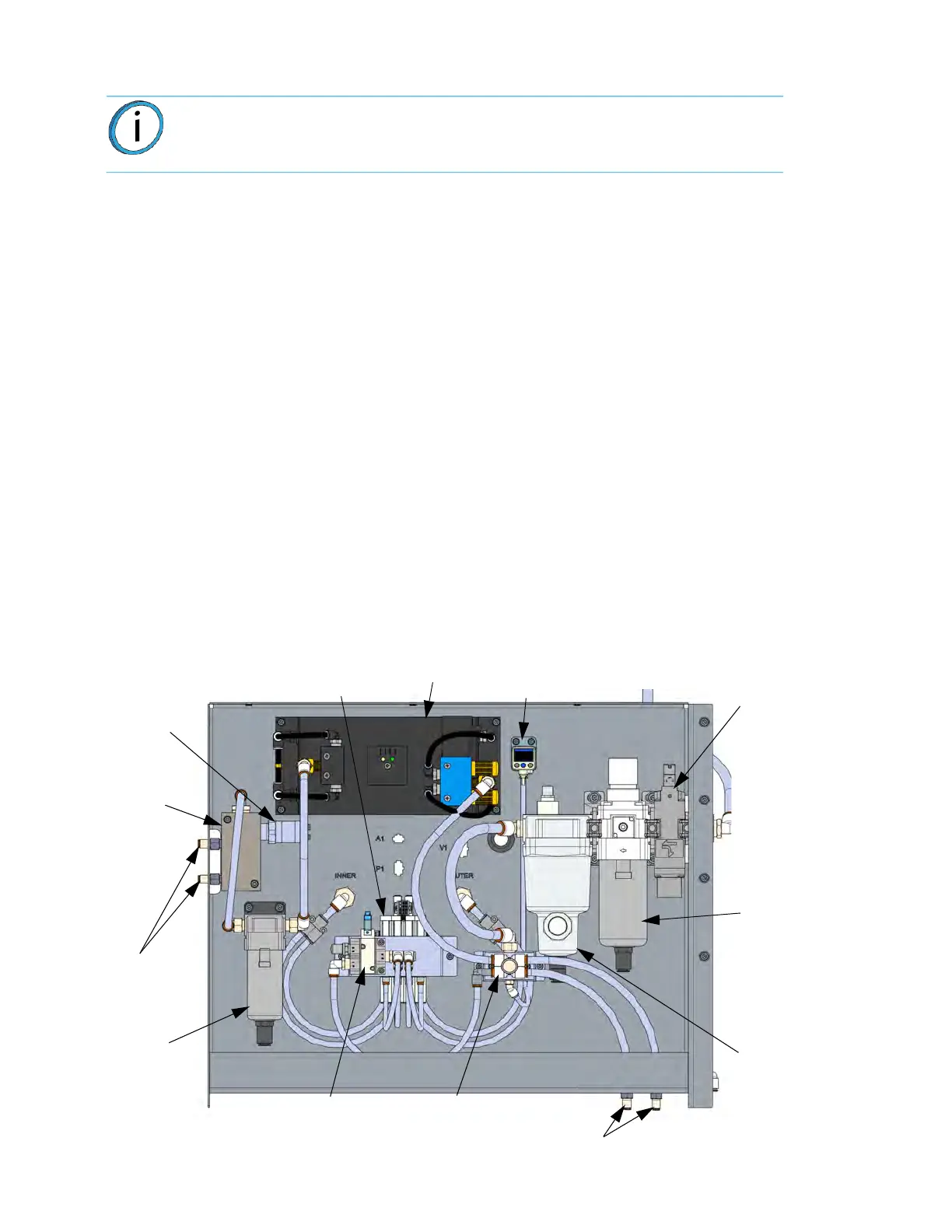

AUXILIARY PANEL GEN III

The auxiliary panel is located on the right side of the system and accessed from the access panels. With the

MAC board interface and control, the auxiliary panel provides two primary functions; vacuum generation and air

drying. These functions are performed using an external compressed air source (non-lubricated) at 90-120 psi).

Because of the large build area offered by the F900, two separate vacuum zones on the vacuum platen are

provided. The zones are identified as the “inner” and “outer” and permit use of either large or small build sheets.

Dried air is supplied to the filament feed path of the system making sure that material delivered to the head does

not become contaminated by moisture that could cause part quality issues.

Auxiliary Panel Components:

• Vacuum Generators & Vacuum Switches With Digital Displays

•

Air Dryer

•

Pressure Switch With Digital Display

•

Main Air Supply Solenoid Valve

•

Pressure Regulator & Particulate Filter

•

Micro-mist Separating Dust & Oil Filter

•

Camera & Lights Cooling Flow Control Orifices

•

Distribution Manifold

•

Vacuum Supply Solenoid Valve

•

Dry Air Dust Filter

•

Dry Air Flow Control Orifices

•

Dew Point Sampling Manifold

•

Dew Point Sensor

Fi

gure 8-3: Au

xiliary Panel Components

Note: The following description and diagram represent Gen III versions serial

number > 2000 or any other printer that is upgraded to an F900.

Air Dryer

with Digital Displays

Pressure Switch

with Digital Display

Main Air Supply

Solenoid Valve

Pressure

Regulator &

Particulate

Filter

Micro-Mist

Separating

Dust & Oil

Filter

Camera & Lights

Cooling Flow

Control Orifices

Distribution

Manifold

Vacuum Supply

Solenoid Valve

Dry Air

Dust Filter

Dry Air

Flow

Control

Orifices

Dew Point

Sensor

Dew Point

Sampling

Manifold

Vacuum Generators & Switches

Loading...

Loading...