26

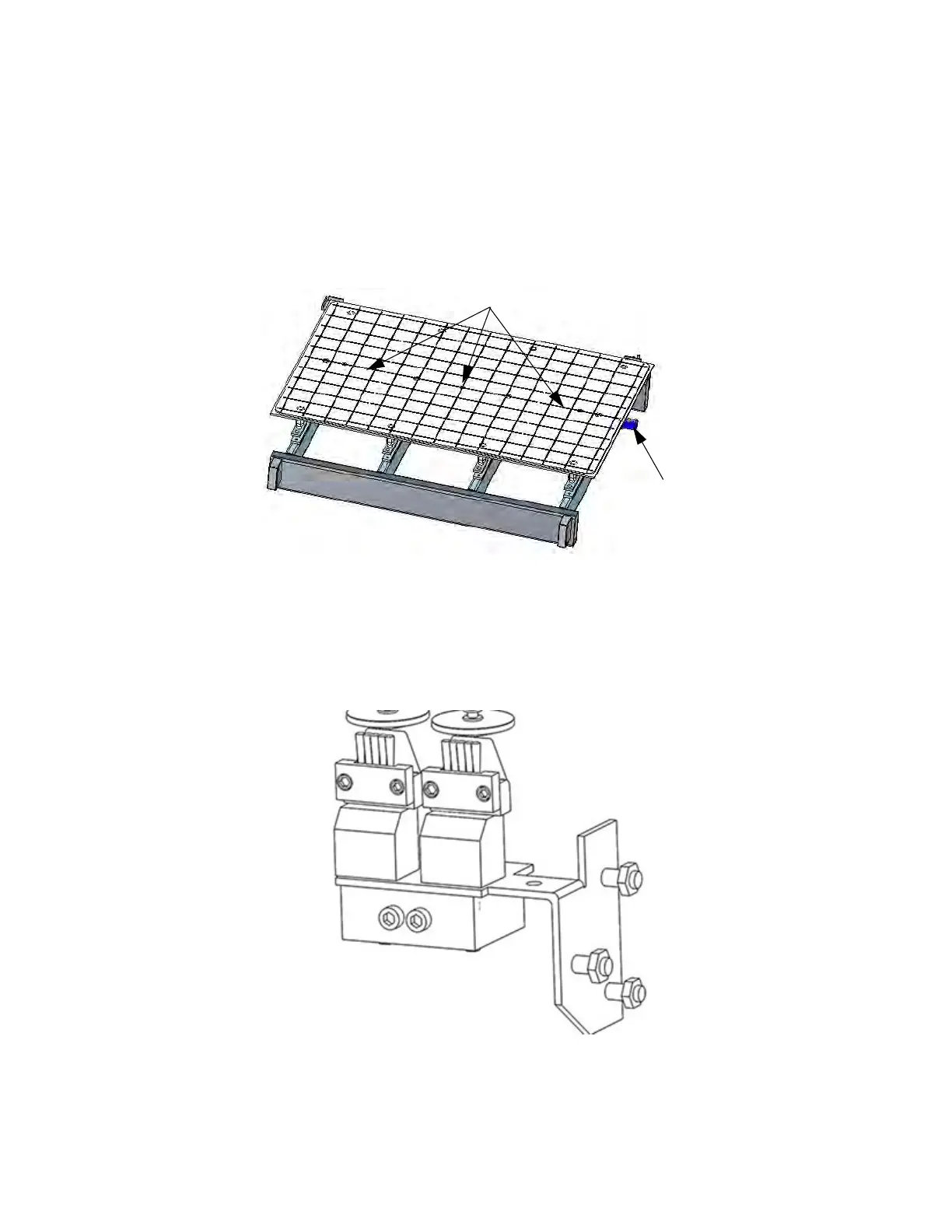

PLATEN

The platen is the surface on which parts are built. A plastic build sheet is held to the 36 in. (91.4 cm) X 24 in.

(61.0 cm) aluminum platen by the vacuum source. The platen has a waffle pattern system into the top surface.

This allows vacuum to pull across the entire surface. A small build sheet 16 in. (40.6 cm) X 18.5 in.

(47.0 cm) can be used in the center zone of the platen.

Debris screens (not a customer removal part) are placed across the vacuum ports to prevent material particles

f

r

om entering the vacuum lines.

Figure 2-14: Va

cuum Platen Components

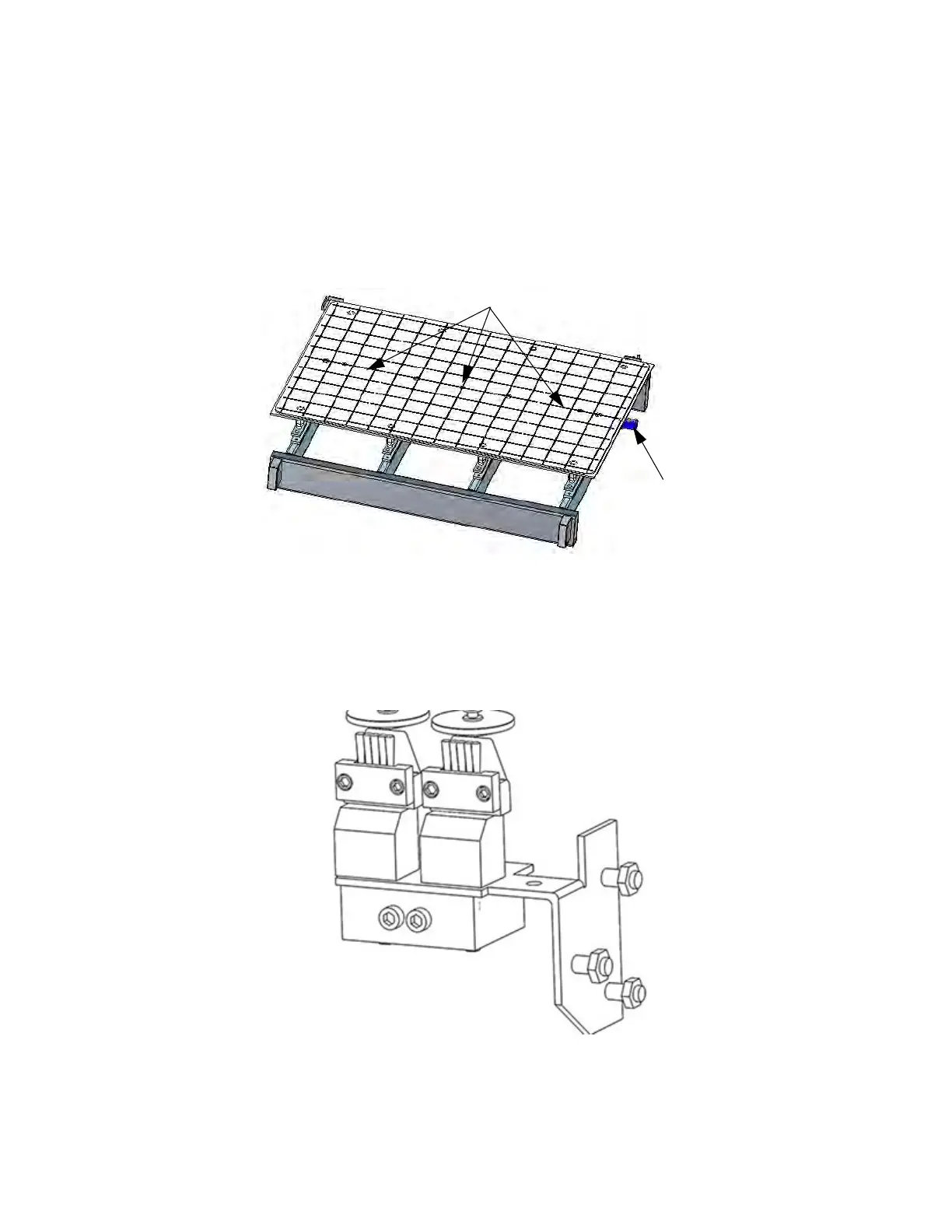

The Tip Cleaning Assembly is located to the front, right side of the oven. The assembly consists of two flicker/

br

ush assemblies (1 for each tip) and a debris chute. The flicker/brush assemblies keep the liquefier tips free of

debris and material buildup. The debris chute directs debris into the purge bucket located under the tip cleaning

assembly.

Figure 2-15: Ti

p Cleaning Assembly

Tip Sensor

Vacuum Ports

and Debris Screens

Loading...

Loading...