Workman HDX Auto Page 4 − 17 Drive Train

IMPORTANT: To prevent speed control system con-

tamination, clean components before disassembly.

4. Remove speed control components as needed using

Figures 17, 19 and 20 as guides. If hydraulic hoses are

removed, discard banjo washers and replace during as-

sembly.

NOTE: If speed limiter assembly (item 2 in Fig. 17)

needs to be removed or disassembled, see Speed Lim-

iter Assembly and Speed Limiter Cover Service in this

section.

Assembly (Fig. 17)

1. Install all removed speed control components using

Figures 17, 19 and 20 as guides.

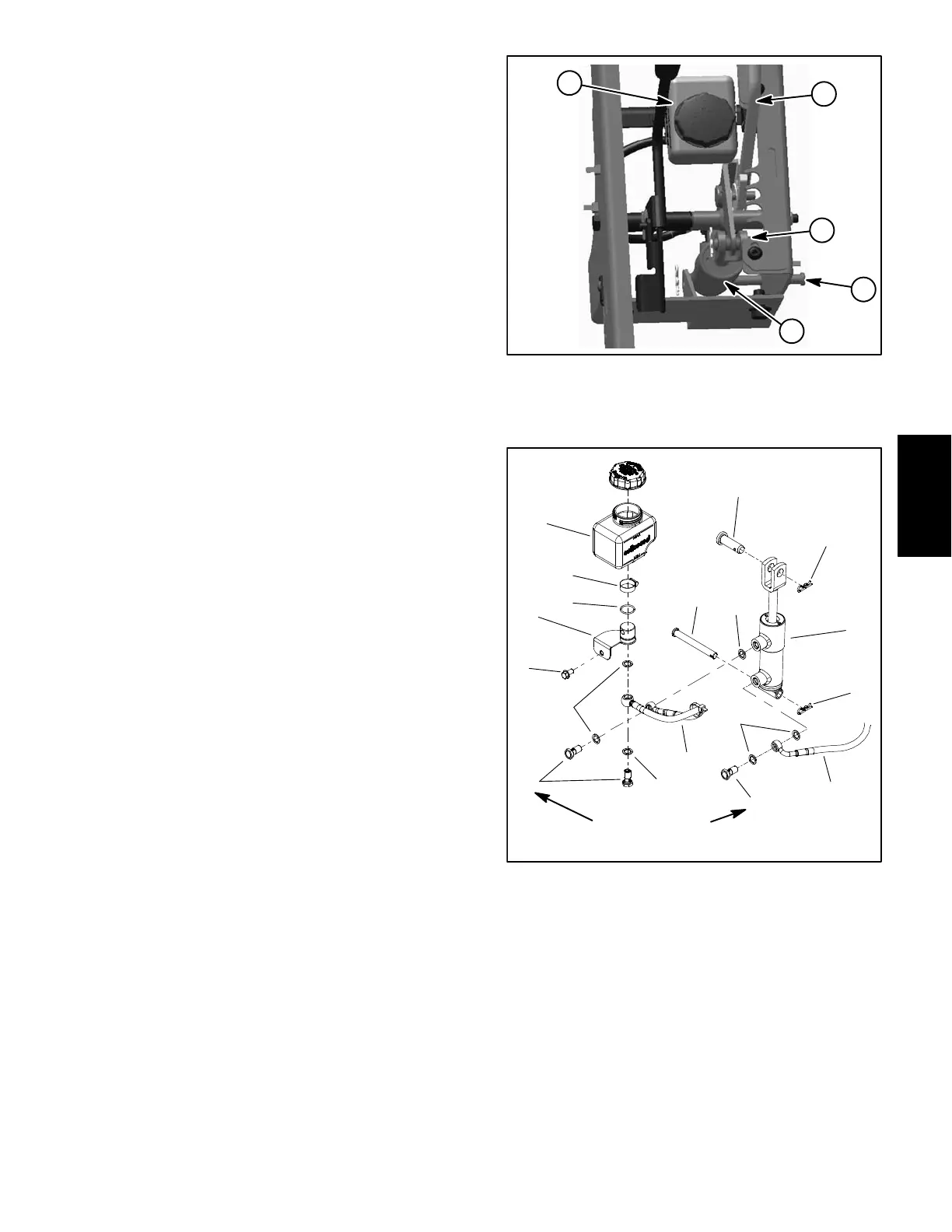

A. If banjo bolts (item 7 in Fig. 20) were removed

from reservoir fitting cylinder, use new banjo washers

(item 6 in Fig. 20) on both sides of hose fitting and

torque banjo bolt from 108 to 132 in−lb (12.3 to 14.9

N−m) during assembly.

2. If hydraulic system was opened during disassembly,

bleed speed control system (see Bleed Speed Control

System in this section).

IMPORTANT: Use DOT 3 brake fluid in the speed

control system.

3. Make sure that fluid level in speed control reservoir

is correct. Add DOT 3 brake fluid to reservoir as needed

to adjust level.

4. Install control plate to seat base and secure with six

(6) washer head screws. Install knobs to speed range

lever and hydraulic lift lever.

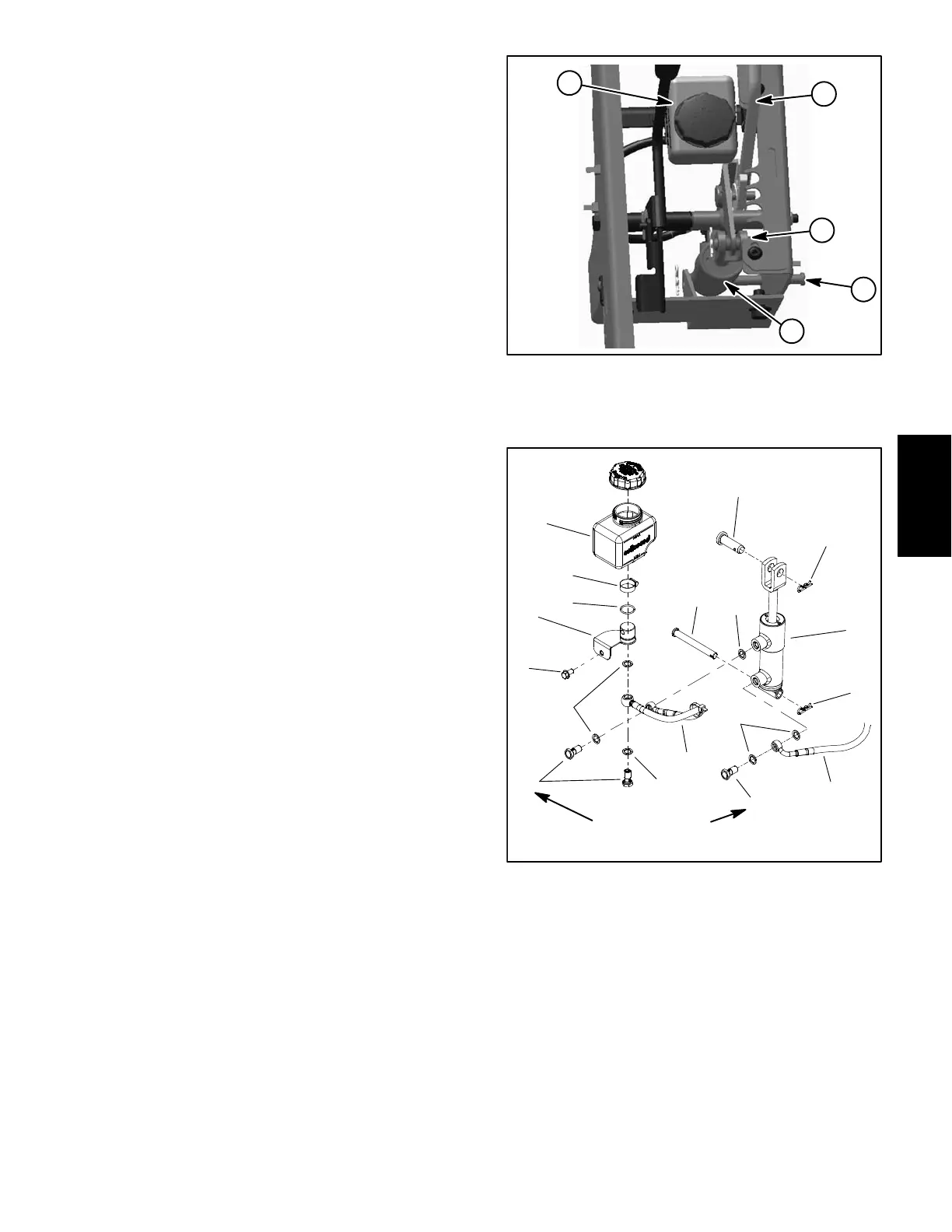

Figure 19

1

5

4

3

2

1. Speed range lever

2. Reservoir

3. Cylinder

4. Clevis pin

5. Clevis pin

Figure 20

1. Reservoir

2. Worm clamp

3. O−ring

4. Reservoir fitting

5. Washer head screw

6. Banjo washer

7. Banjo bolt

8. Hose

9. Cylinder

10. Clevis pin

11. Hair pin

12. Clevis pin

13. Speed control hose

2

3

6

8

9

10

11

13

1

5

7

12

4

6

6

7

11

6

108 to 132 in−lb

(12.3 to 14.9 N−m)

SafetyProduct Records

Drive Train

Loading...

Loading...