Workman HDX Auto Page 4 − 29 Drive Train

Disassembly (Fig. 31)

1. Remove lock nut (item 3) from each of the shoulder

screws (item 2). Discard lock nuts after removal.

2. Slide shoulder screw from each of the clutch weights

(item 4) and then remove weights from clutch.

3. Clean all dust and debris from clutch components

with a soft bristle brush. If necessary, use water to re-

move dirt and dry immediately with compressed air to re-

move all dirt and water. Remove any remaining debris

with a fast drying contact or brake parts cleaner. Focus

debris removal on and around moving components.

Inspection

NOTE: If primary clutch wear or damage occurs, clutch

replacement may be necessary. Refer to your parts cat-

alog to identify individual primary clutch components

that are available.

1. Inspect the tapered ends of the engine crankshaft

and stationary sheave of primary clutch. If either is se-

verely damaged, replace component as damage to the

taper will allow loosening of the clutch during operation.

2. Clean and inspect shoulder screws (item 2). If the

shoulder area of the screws is worn or if the threads are

damaged, replace the screws.

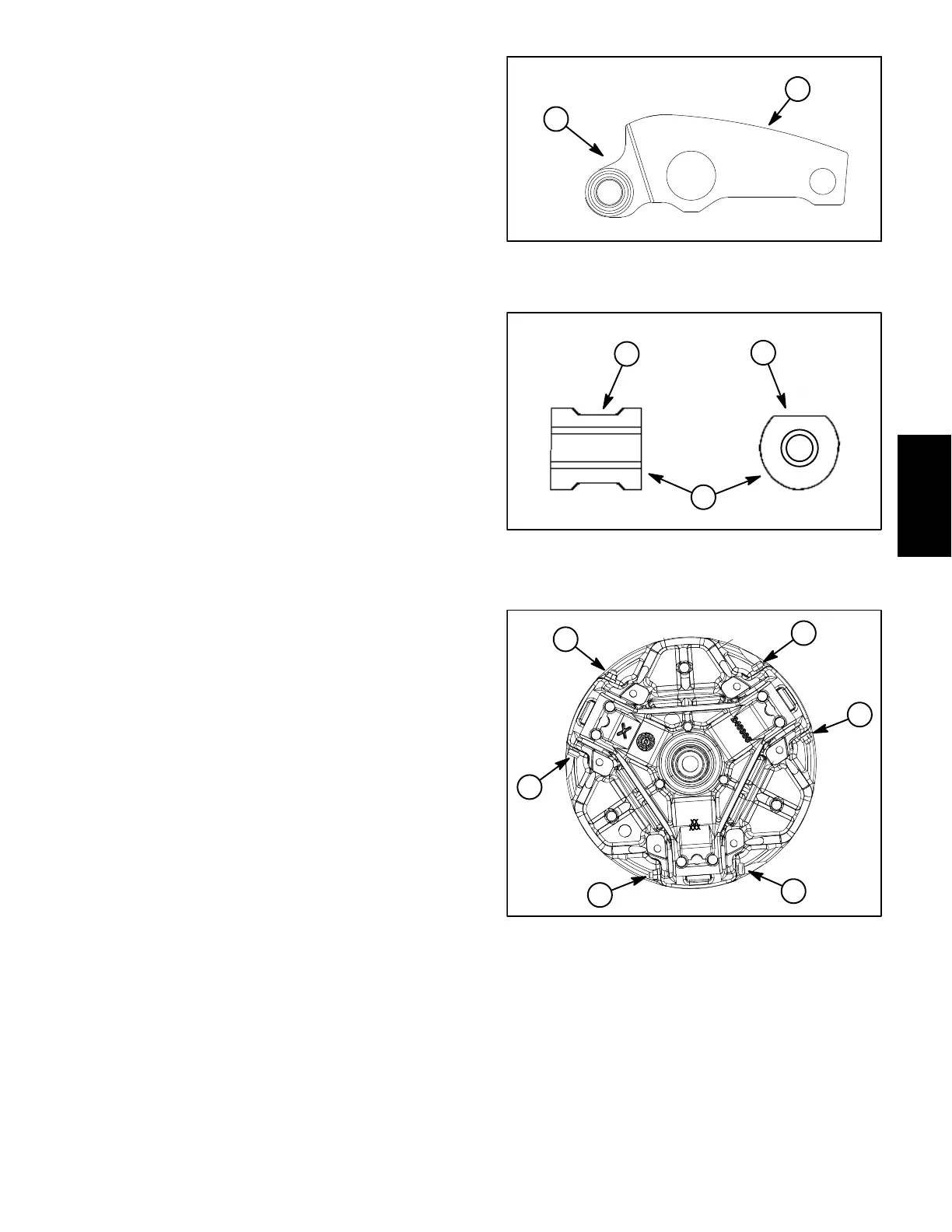

3. Check the contact surface of the clutch weights

(Fig.4). If surface is worn or damaged, replace all three

(3) clutch weights as a set.

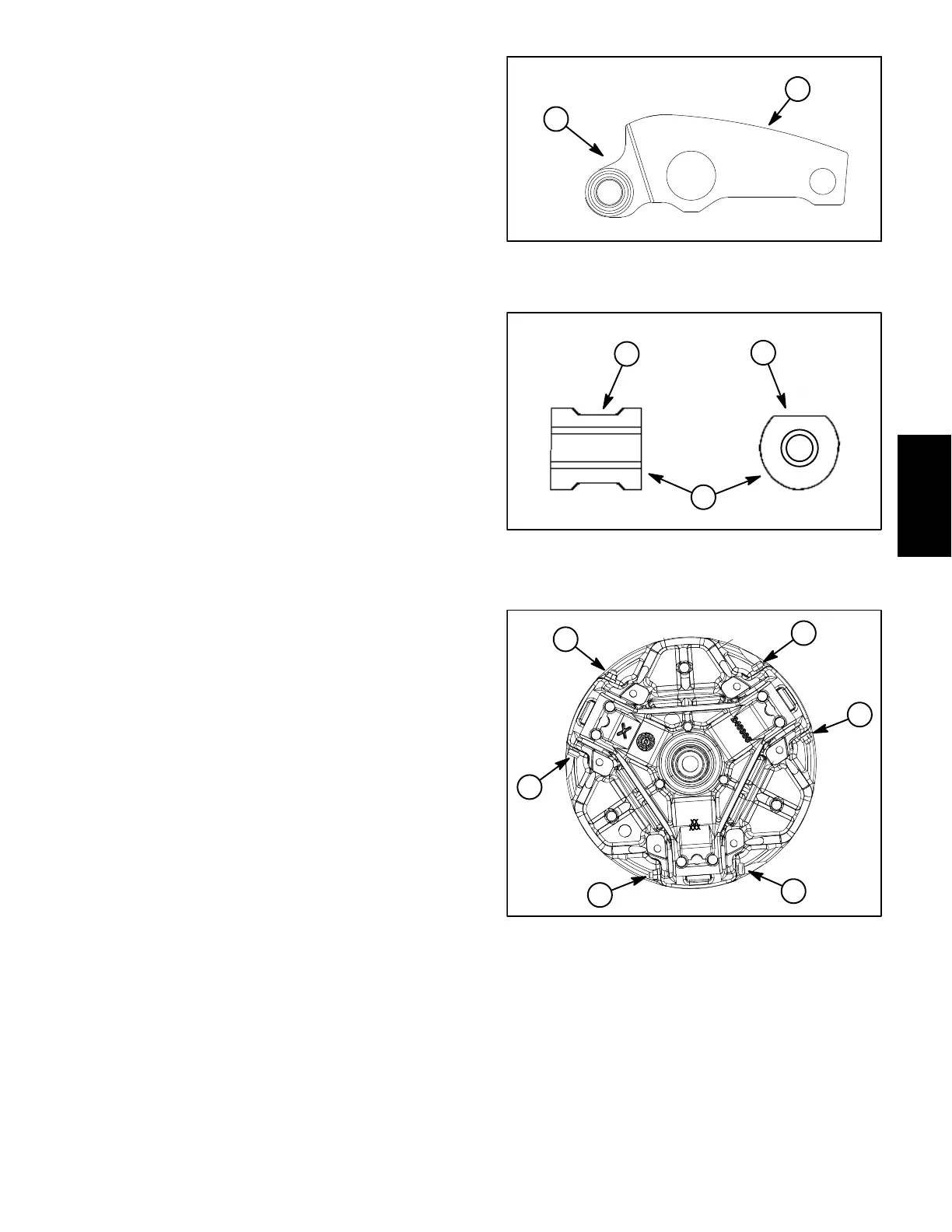

4. Check the rollers in the spider assembly for binding

or wear (Fig. 33). If binding or uneven wear is found, re-

place primary clutch assembly.

5. Check the belt contact surfaces of the movable and

stationary sheaves. Remove any belt material from

sheave faces with a fine abrasive pad or fine steel wool.

If sheave surfaces are worn, replace primary clutch.

Assembly (Fig. 31)

IMPORTANT: For proper clutch operation, DO NOT

lubricate clutch components during assembly.

IMPORTANT: To maintain the balance of the clutch,

all shoulder screws must be installed with their

threads pointing in a clockwise direction (Fig. 34).

1. Position clutch weights to moveable sheave and

slide shoulder screw into sheave and weight. Make sure

that screw threads are pointing in a clockwise direction.

2. Install new lock nuts on the shoulder screws. DO

NOT reuse removed lock nuts. Tighten nuts until they

contact screw shoulder and then torque nuts from 40 to

50 in−lb (4.6 to 5.6 N−m).

1. Clutch weight 2. Contact surface

Figure 32

2

1

1. Roller

2. Weight contact surface

3. Roller uneven wear

Figure 33

2

1

3

1. Shoulder screw head 2. Lock nut

Figure 34

2

1

1

1

2

2

SafetyProduct Records

Drive Train

Loading...

Loading...