Modbus TCP gateway

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

Configuration of the Modbus-TCP interface to the PLC - how the

data are transferred

910785291

Application characteristics for Modbus TCP:

• Support of standard addressing conventions for Modbus TCP.

• Master and slave operation

Requirements for the PLC for Modbus TCP:

• The PLC must support the Modbus TCP protocol.

• The PLC must either support the Read Holding Registers and Write Multiple Registers

commands or the Read/Write Multiple Registers command.

The configuration steps in this section determine how the data are to be transmitted to the

higher-level PLC.

There are two different methods of transmission for each transmission direction, i.e. sa-

mosPRO COMPACT

and

samosPRO:

• Receiving method Polling/PLC requests (gateway as slave)

This method allows the PLC regularly to request data using polling.

When this method is used, the data are returned in the response to the data request. The

PLC requests data by accessing the receiving data address of the SP-COP2-ENI module via

a read-holding-register telegram.

• The master receiving method gateway writes to the PLC (auto-update, gateway as master)

When the SP-EN-MOD module sends data to the PLC, these are immediately written to a

memory location in the PLC.

• Slave transmission method - PLC writes (gateway as slave)

With this method, the PLC sends telegrams to the SP-COP2-ENI module to write to the

output data sets. For this purpose, the PLC writes data into defined addresses.

• The master transmission method gateway reads from the PLC (auto-update, gateway as

master)

With the master transmission method, the SP-COP2-ENI module polls the PLC for the out-

put data sets.

The configuration is regarded as faulty when the IP address of the PLC is zero and the read

transfer mode and/or write transfer mode has been set for the master.

The number of possible connections to the PLC depends on whether the SP-COP2-ENI module

is operated as a master or as a slave. Depending on the setting, up to 6 PLCs can simultaneou-

sly address the SP-COP2-ENI module.

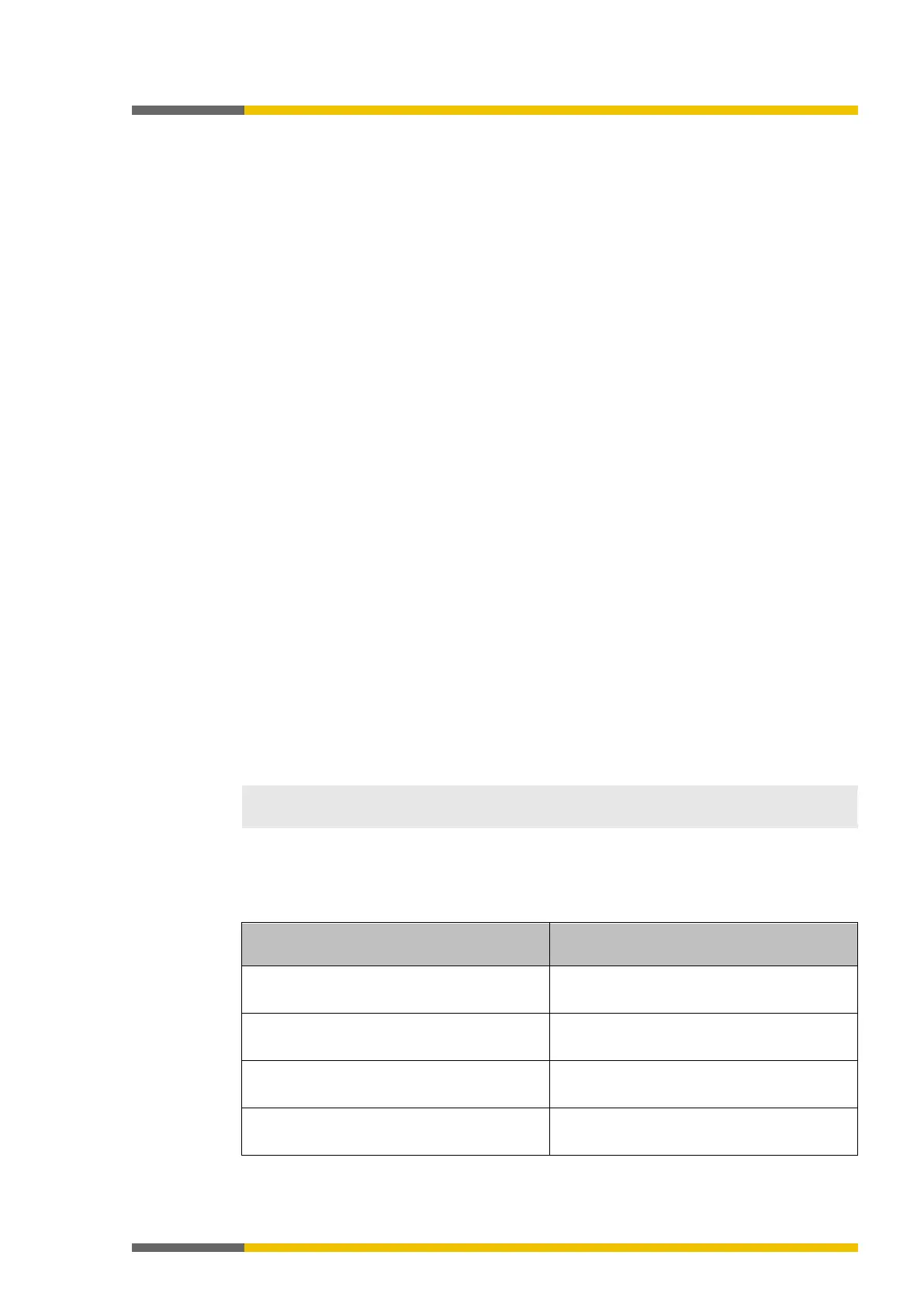

Table 18: Maximum number of possible Modbus TCP connections for the individual operating modes

Operating mode of the SP-COP2-ENI modu-

le

Maximum number of connections

Output data (to the PLC): Gateway writes

Input data (from PLC): Gateway reads

1 outgoing connection

Output data (to the PLC): Gateway writes

Input data (from PLC): PLC writes

1 outgoing connection

Output data (to the PLC): PLC reads

Input data (from PLC): Gateway reads

6 outgoing connections

Output data (to the PLC): PLC reads

Input data (from PLC): PLC writes

6 outgoing connections

The following table describes the configuration, depending on the transmission method:

Loading...

Loading...