Modbus TCP gateway

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

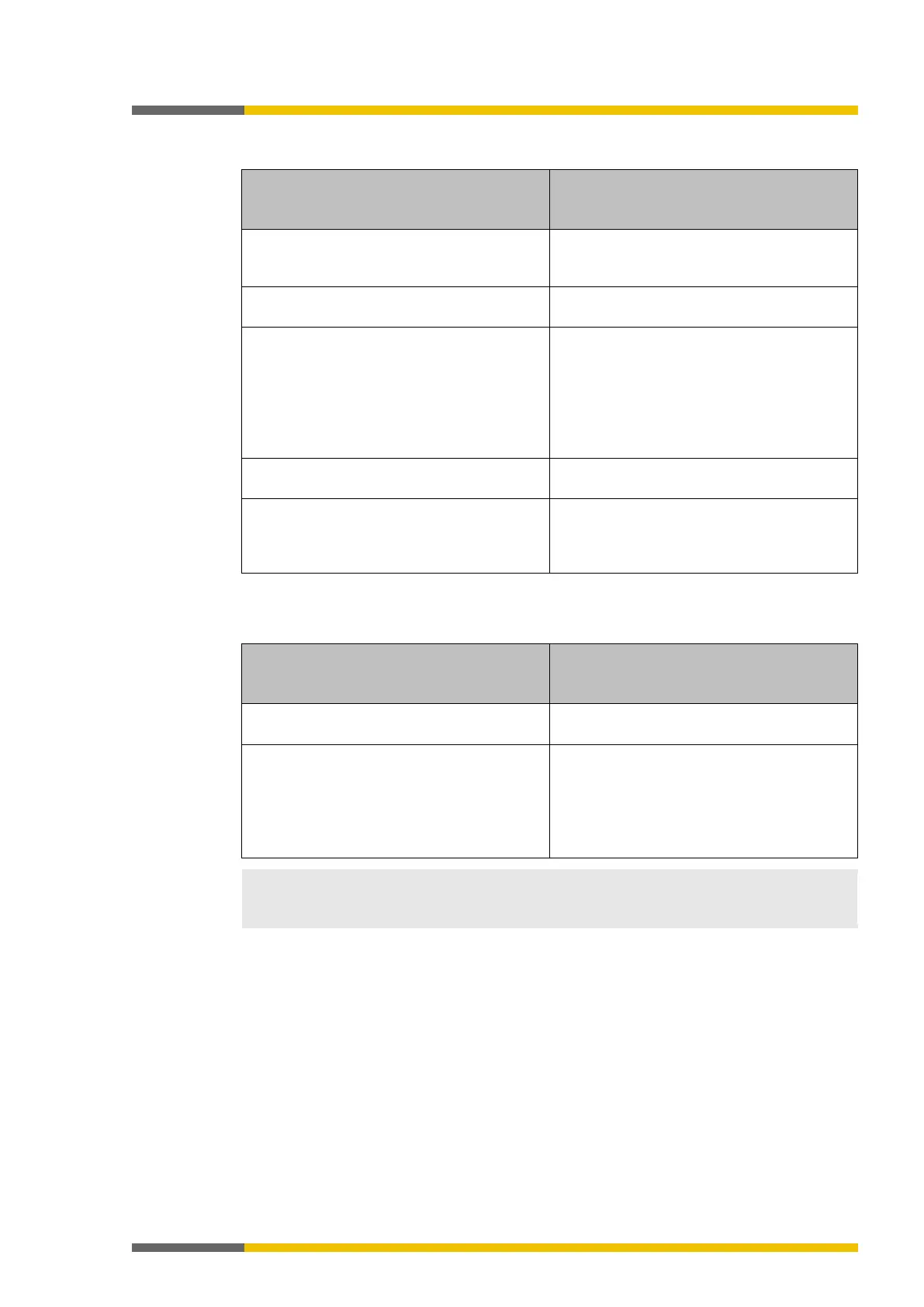

Gateway is master

Table 19: Configuration directive – gateway as master

Essential settings in the gateway configura-

tion (via SP-COP2-ENI)

Settings required for the PLC program

and/or in the Modbus TCP configuration

tool

Choose

Gateway writes to tag/file

and/or

Gateway reads from register

to configure

–

Se

lect which data are to be written to the PLC

or read from it.

–

Define where the selected data in the PLC

memory are to be written to: Enter the regis-

ter address(es).

Example: "40001" and/or you can determine

from which location in the PLC memory the

sele

cted data are to be read: Enter the register

addresses.

Ensure that the addresses allocated in the

samosPRO

are available and that they contain

the data intended for the samosPRO- system.

Choose how often these data are to be

–

Define from and to where the data in the

Modbus-TCP network are to be read and

written: Enter the IP address and the slot

number of the PLC controller.

–

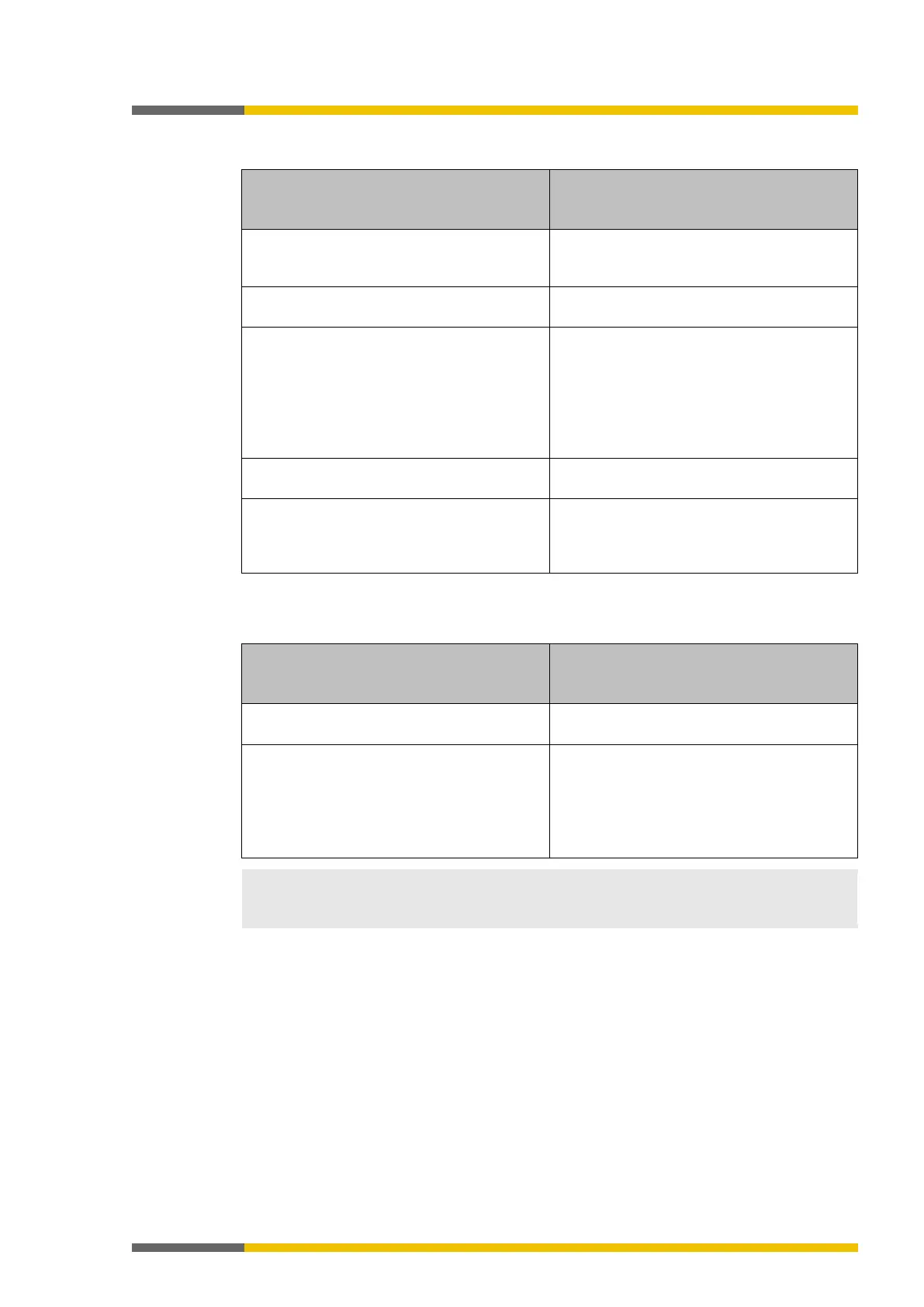

Gateway as slave

Table 20: Configuration directive – gateway as slave

Essential settings in the gateway configura-

tion (via SP-COP2-ENI)

Settings required for the PLC program

and/or in the Modbus TCP configuration

tool

Select

and

in the

gateway configuration dialog.

–

– Select which data are to be written to the

gateway or read from it.

Ensure that the PLC program writes the data

into the addresses allocated to the gateway

(see Table "

Data addressing for the SP-COP2-

ENI as recipient [ch. 6.3, p. 58]

").

The address settings for the Modbus TCP gateway are 1-based. Please subtract 1 from the

register address set in samosPLAN5+ for a 0-based address setting.

Example: Register 1100 corresponds to the Modbus address 1099.

Loading...

Loading...