Operation

0515−1/A1

Winterthur Gas & Diesel Ltd.

3/ 7

2.3.1 One Actuator is Defective

1) Do a check of the control signals from

the ECS and the electrical cables. If

necessary, replace the electrical

cables.

2) Make sure that the toothed rack (3)

moves freely (see Fig. 1).

3) Move the toothed rack (3) to the 0%

fuel position.

4) Install two distance pieces (6, tool

94555) to the toothed rack (3) on the

fuel pump (1) that has the defective

actuator.

5) Replace the defective actuator as soon

as possible (see the Maintenance

Manual, 5801−1 Regulating Linkage).

6) If different power outputs are

necessary, you can lock the actuator in

other positions (50% fuel, or 100% fuel)

see step 7 to step 9.

7) Remove the six screws from the cover

(2) then remove the cover.

8) For 50% fuel, do steps a) and step b):

a) Move the toothed rack (3) to the

50% fuel position.

b) Install one distance piece (6) on

each end of the toothed rack (3).

9) For 100% fuel, do step a) and step b):

a) Move the toothed rack to the

100% fuel position.

b) Install two distance pieces (6) on

the toothed rack.

Note: Fuel pressure control through the

PCV must be prevented if

possible.

Fig. 1: Fuel Pump Actuator

2014

Faults in High Pressure Fuel System

1

2

I

WCH00832

3

4

I

5

3

WCH00832

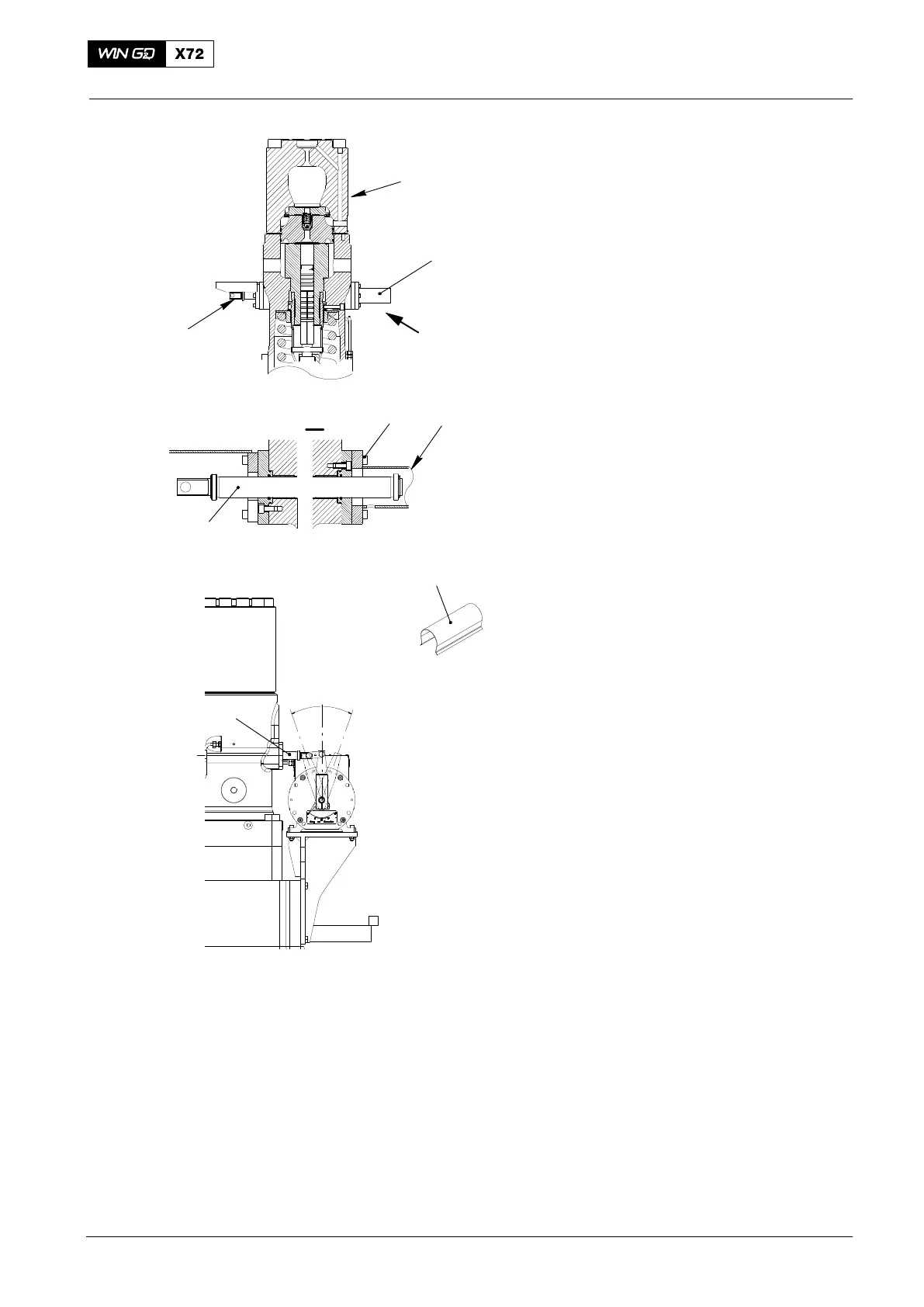

6

WCH02318

100%

50%

FUEL

0%

WCH02318

3

Actuator shown in

50% fuel position

94555

Loading...

Loading...