Operation

0590−1/A1

Winterthur Gas & Diesel Ltd.

1/ 2

Defective Turbocharger

1. General

If a turbocharger becomes defective, you must shut down the engine as quickly as

possible to prevent damage.

If repair or replacement of a turbocharger is not immediately possible, the engine can

operate in Emergency Operation at decreased load after the procedure below is

completed.

In Emergency Operation, you must operate the engine only for as long as necessary

(see 0500−1, paragraph 2 Decreased Power Output).

The loads (outputs) given are guidance values, which are related to the condition of

the engine. It is possible that these values will be decreased.

2. Defective Conditions

2.1 Condition One

One turbocharger is defective.

2.1.1 Procedure

The engine load output is approximately

50% of the CMCR. This is related to the

output of the auxiliary blowers.

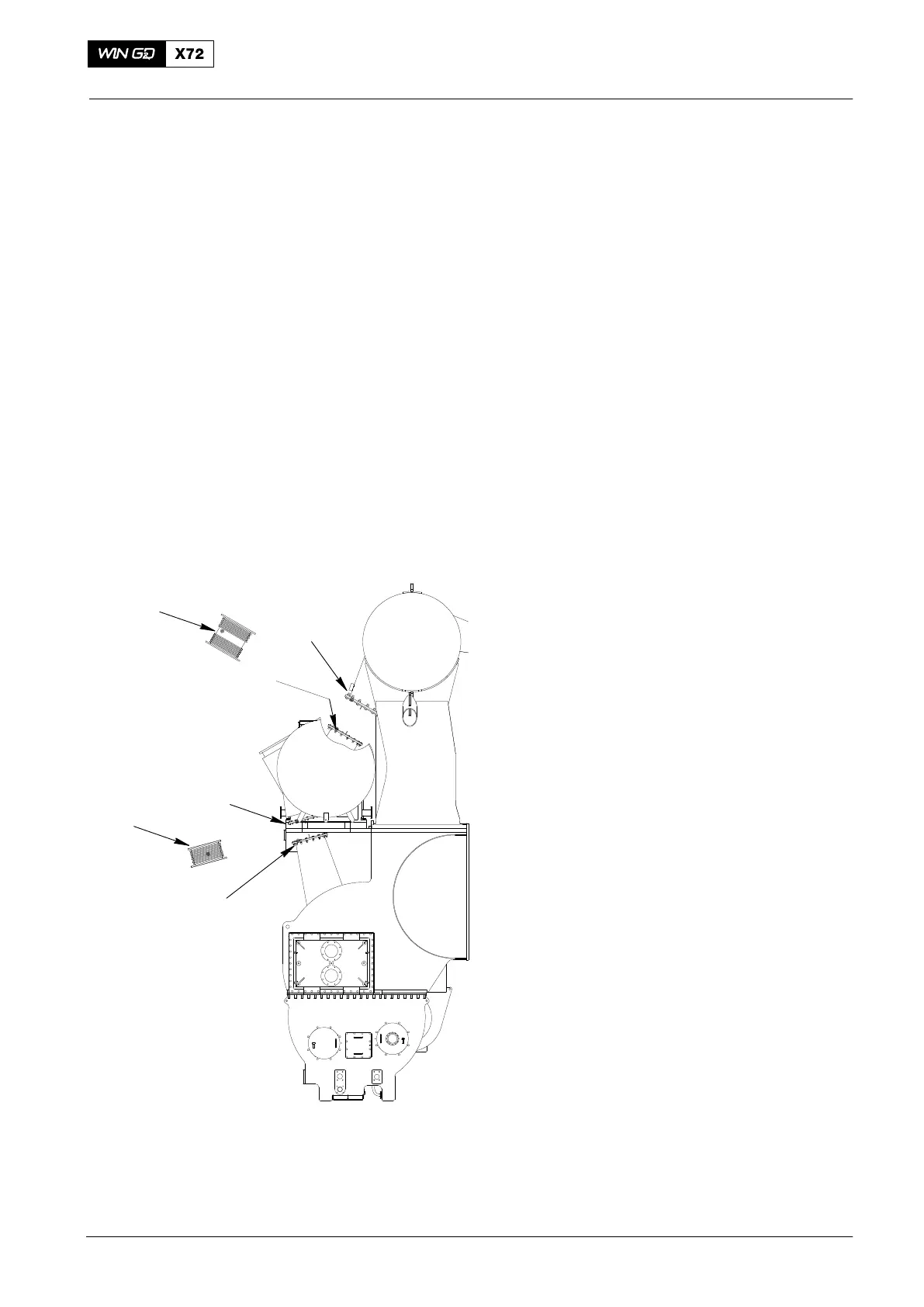

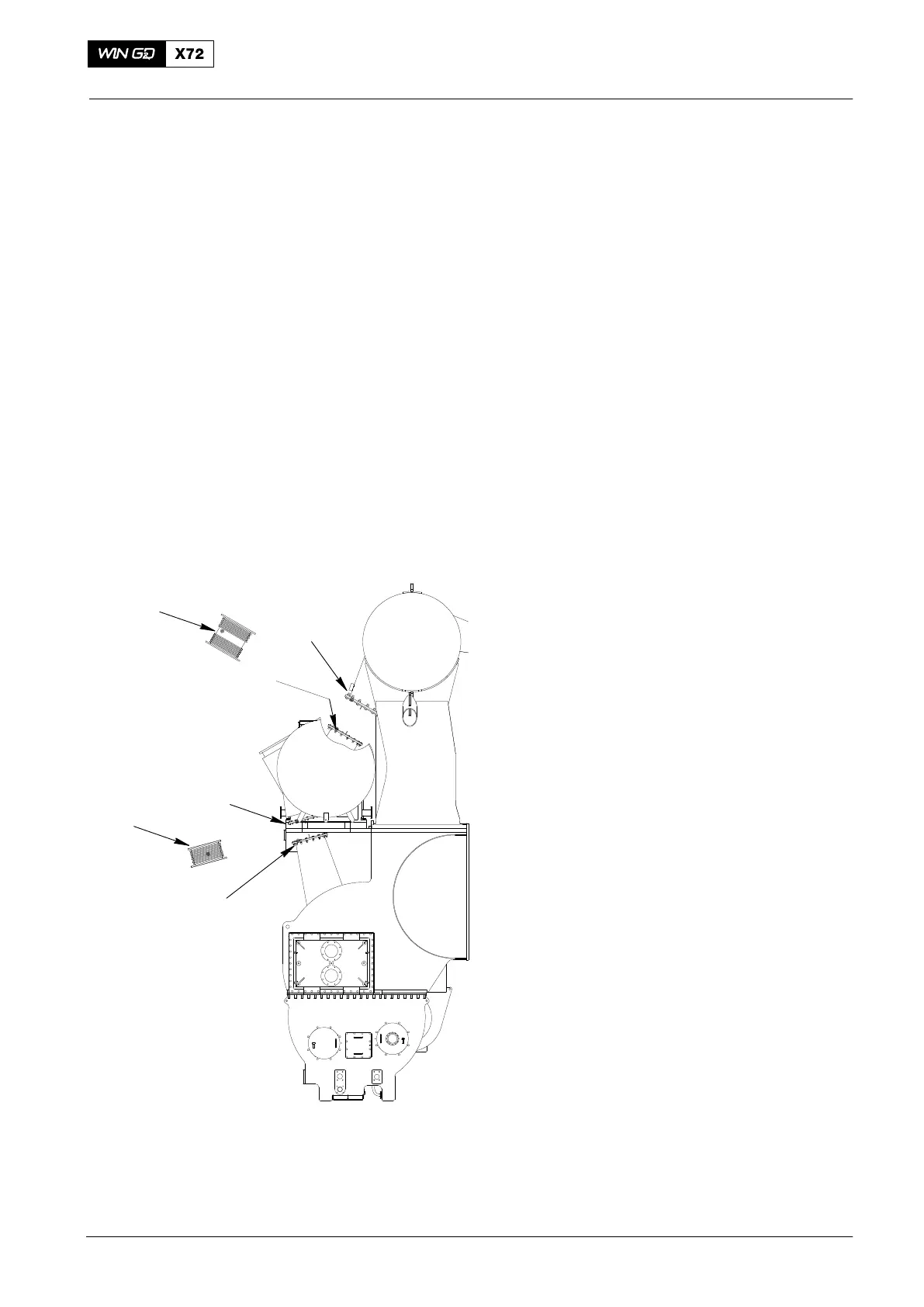

1) Lock the rotor of the turbocharger (see

the turbocharger manual).

2) Remove the expansion joint (6, Fig. 1)

from the defective turbocharger and the

exhaust manifold.

3) Install the blind flanges (1) and (2, tool

94653).

4) Remove the expansion joint (5) from

the defective turbocharger air outlet

and the diffusor.

Note: Install the blind flange (3) only if

air flows in through a suction duct.

5) Install the blind flanges (3, tool 94655)

and (4, tool 94653).

The scavenge air pressure, turbocharger

speed and firing pressures must not be

higher than during usual operation.

Note: Before you start the turbocharger,

make sure that you remove the

plugs from the oil supply pipes.

2014

Operation during Unusual Conditions

1

2

3

4

6

5

Fig. 1: Defective Condition One

Loading...

Loading...