Operation

0820−1/A1

Winterthur Gas & Diesel Ltd.

3/ 7

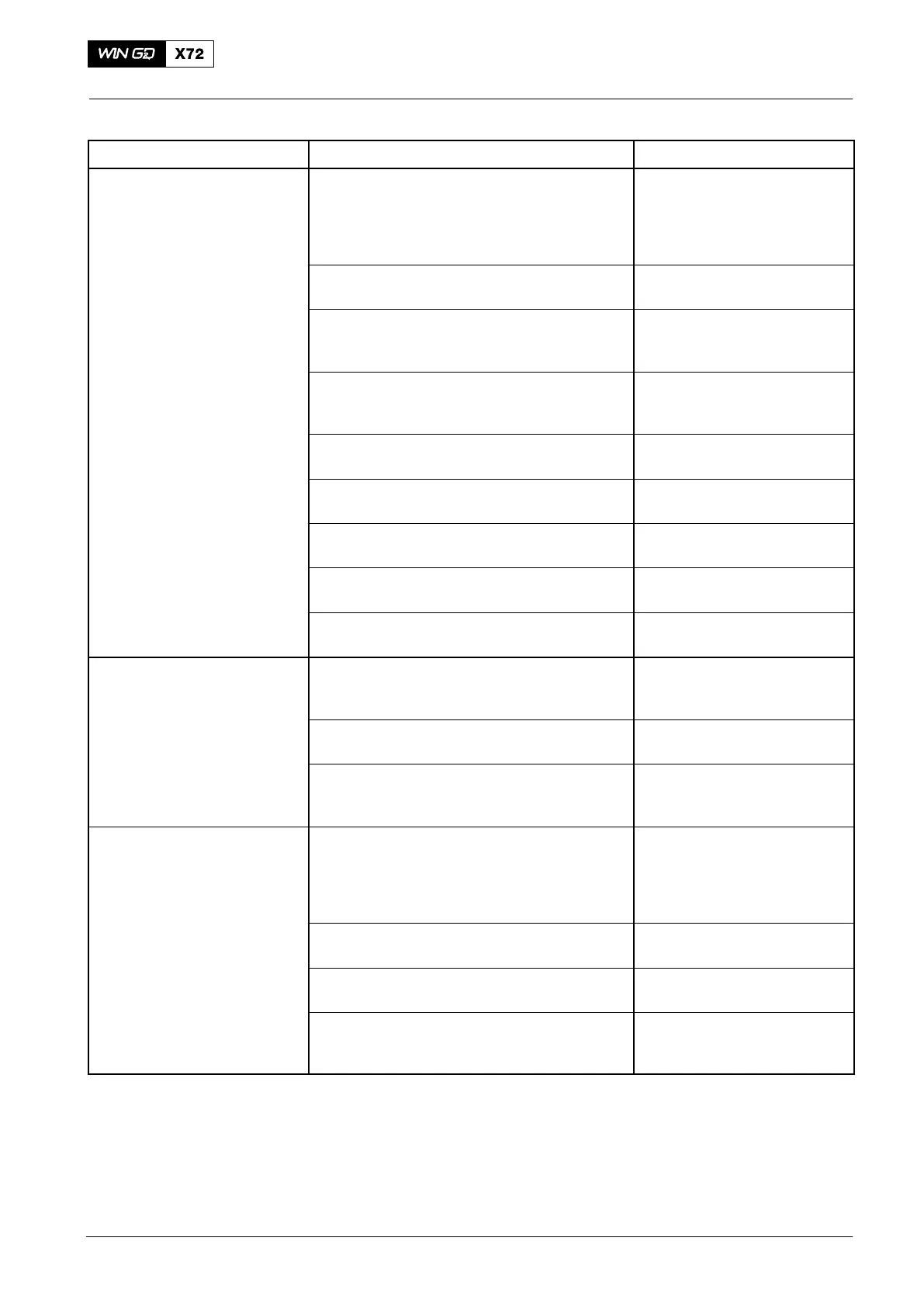

Problem Possible Causes Procedure

There is smoke from the

exhaust

Air supply is not sufficient. Unwanted material

in: the exhaust side or air side of the

turbocharger, scavenge air cooler, air flaps in

the receiver, scavenge ports in cylinder liners

or in the exhaust boiler

See Scavenge air pressure

decreases

The engine has too much load Decrease the fuel injection

quantity

The engine operates with too much cylinder

lubricating oil

See 7218−1, paragraph 6.4

Adjustment − lubricating oil

feed rate

Injection nozzles do not completely change

the fuel into a spray, e.g. because there

trumpets, worn or blocked spray holes

Clean the parts. Do a check

to adjust the parts, or replace

the parts

The fuel is incorrect, or the viscosity is too

high (not not sufficiently heated)

See 0270−1 paragraph 2

The compression pressure too low. The

piston rings have leaks, exhaust valve leaks

Replace the piston rings,

grind the valve seat and head

Bores in upper housing of the exhaust valve

are clogged. Exhaust valves close too late

Do a check and clean the

parts

The servo oil pressure is too low, the servo

oil pump control is defective, oil leakage

Do a check of the oil flow.

Find and repair the leaks

An auxiliary blower operates at part load, or

the two auxiliary blowers do no operate.

Set the auxiliary blowers to on

Engine operates irregularly or

misfires at times, on one or all

cylinders

There is high water quantity in the fuel See 0720−1, paragraph 2

Treatment of HFO and

treatment plant

The fuel temperature upstream of the fuel

pumps is too low or too high

See 0270−1, paragraph 2

The pressure in the fuel rail is too low. The

pressure control valve is defective. One of

the fuel pumps does not supply fuel

See 0515−1, paragraph 5. Do

a check of the pressure

transmitter.

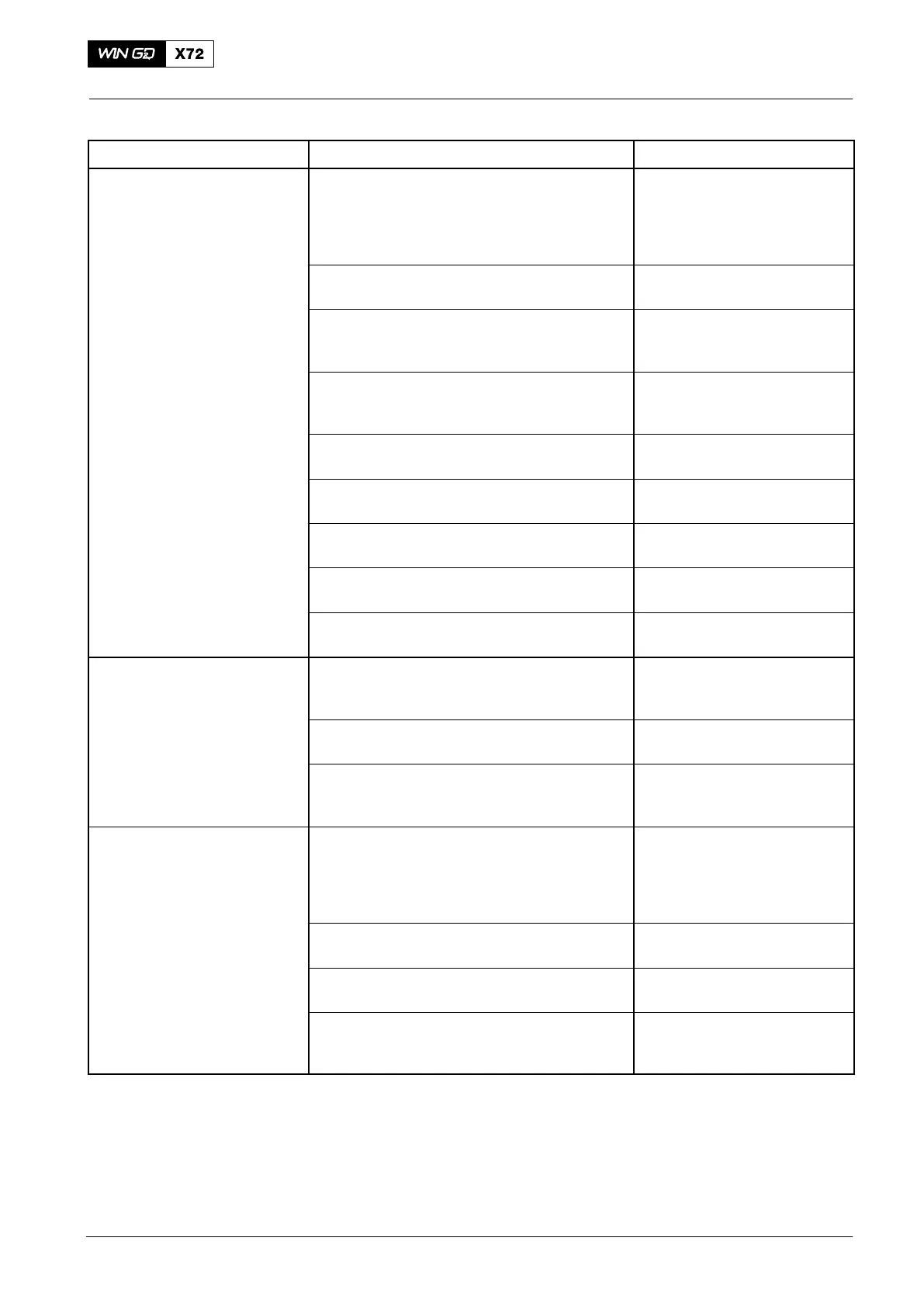

The engine stops without

operator input (without a

shut-down indication)

The fuel daily tank is empty, or fuel supply is

stopped. The fuel filters are blocked. The

booster pump is defective. Defective

switching. The fuel rail pressure is too low.

The fuel system leaks.

Fill the daily tank. Clean the

filter. Find other causes and

repair the defects. Find and

repair leaks.

There is no electrical power supply to the

engine control system (ECS)

Repair the cause and start

the ECS

The speed setting system is defective, e.g.

broken cables

Repair the fault

The engine stops in heavy sea Set the Heavy Sea Mode to

on (see 4002−2, paragraph

3.10 User parameters)

2014

Irregular Operation

Loading...

Loading...