Operation0820−1/A1

Winterthur Gas & Diesel Ltd.

4/ 7

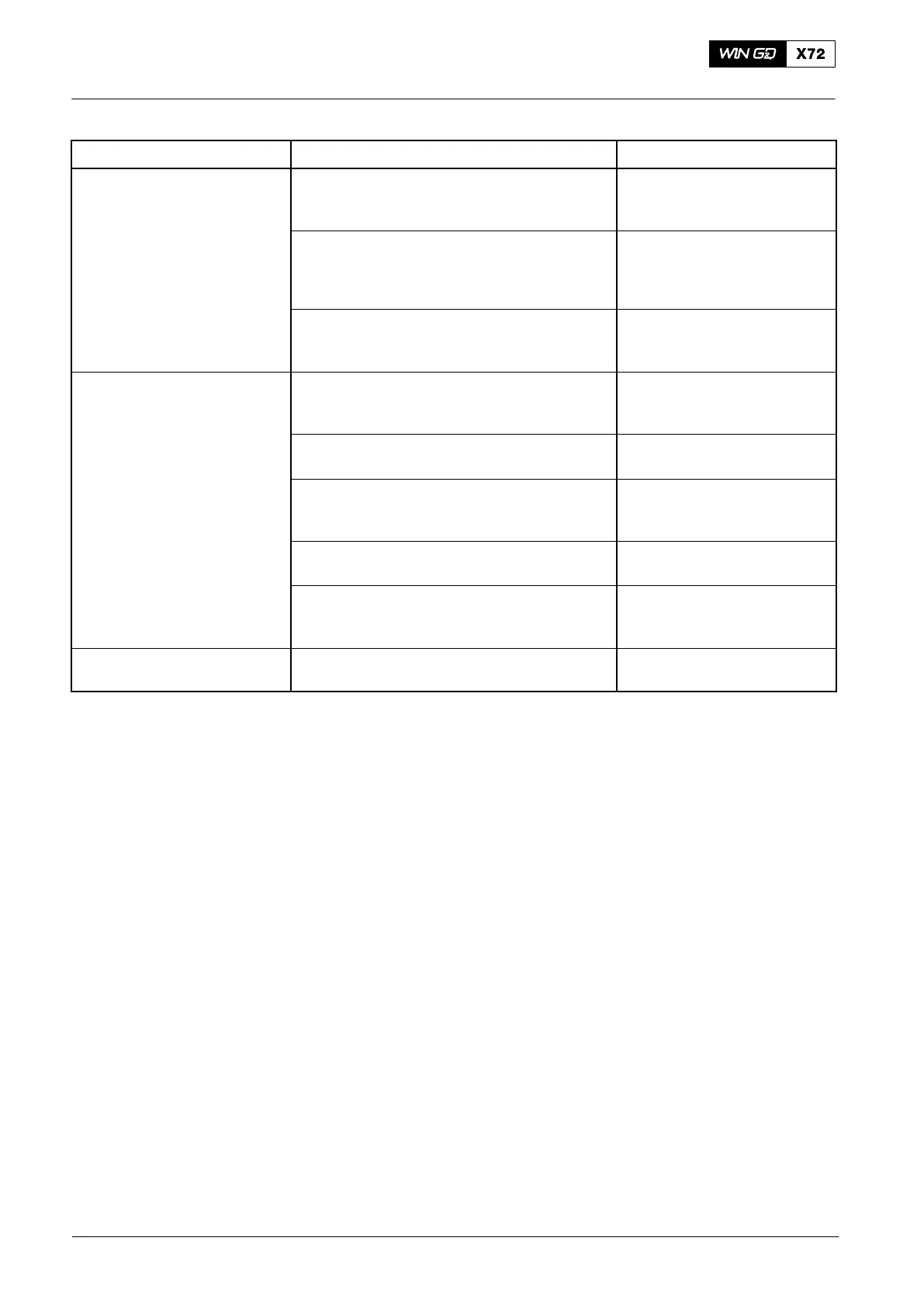

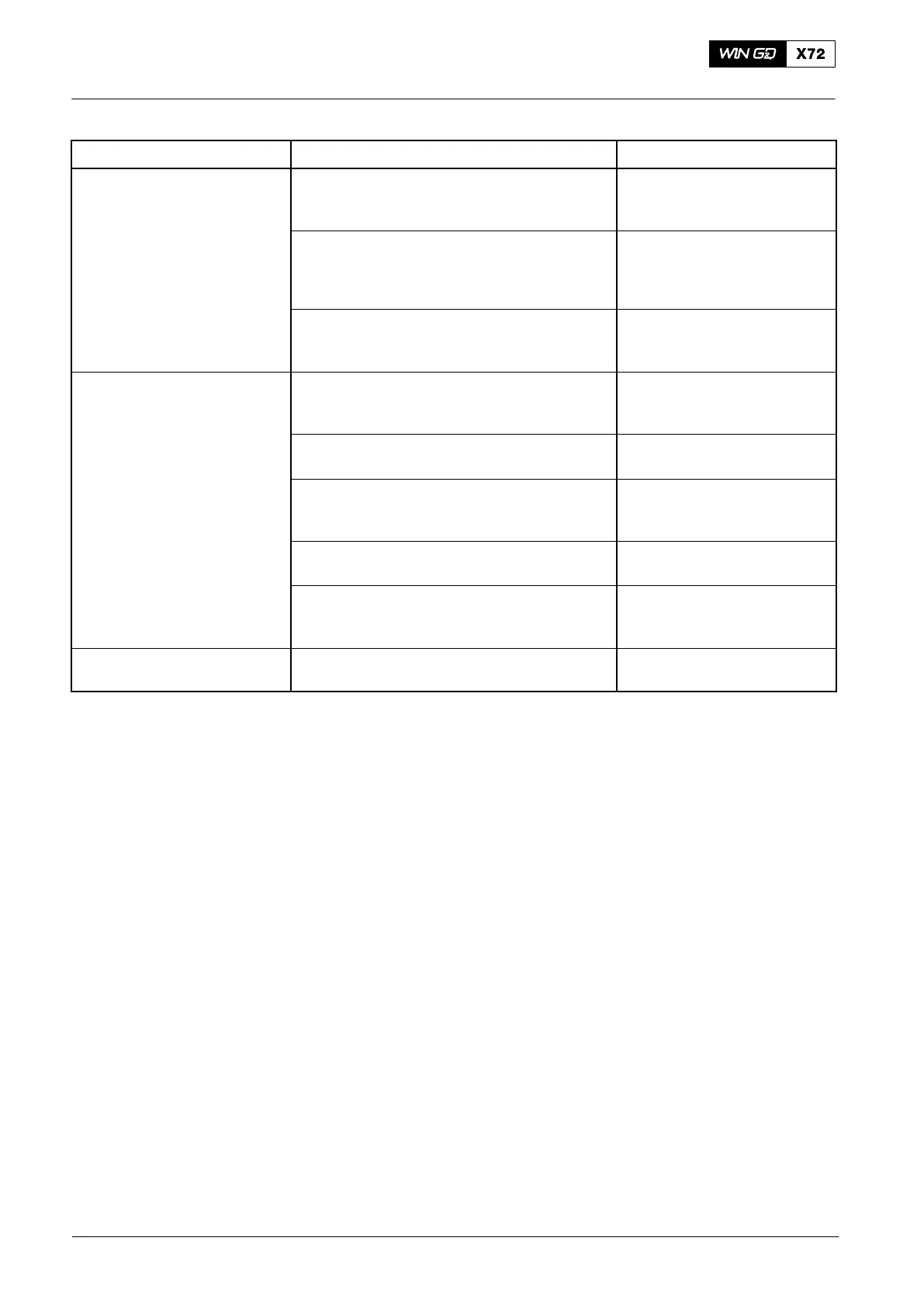

Problem Possible Causes Procedure

Irregular operation of the

cylinder cooling water system

Air collects in the cooling spaces or in the

pipes because pressure release is not

sufficient

Release the pressure

Pressure increases and

decreases quickly

There is a decrease of static pressure at the

inlet to the cooling water pump because of a

blockage in the return pipe or the expansion

tank has drained

See the plant instructions

The exhaust gases go into the cooling water

because of a crack in the cylinder liner,

cylinder cover, valve cage

See 0545−1 Operation with

Water Leakage into the

Combustion Chamber.

Increased cooling water

temperature at the outlet of a

cylinder

The shut-off valves in the pipes of the related

cylinders were accidentally closed, or

defective

Open the shut-off valves or

replace them.

The pressure in the cooling spaces is not

sufficiently released

Release the pressure

The cooling water pipes or water channels

are blocked. The water flow is not sufficient.

See Cooling 0760−1 Cooling

Water / Cooling Water

Treatment

The piston is too hot See 0840−1 Problems and

Damage with Engine Parts.

The exhaust gases go into the cooling water

because of a crack (cylinder liner, cylinder

cover, valve cage)

See 0545−1 Operation with

Water Leakage into the Com-

bustion Chamber

Increased cooling water

temperature on all cylinders

Plant side is defective (regulating valve,

cooling water cooler etc.)

See plant instructions

2. Cylinder Lubrication

If the cylinder lubrication does not operate correctly, the piston rings and cylinder

liners will wear quickly. Also, the piston can seize. Only in emergencies, and then at

decreased power and only for the minimum possible time, can an engine operate

without cylinder lubrication.

If the cylinder lubricating system does not operate correctly, this causes failure

indications to show in the ECS, which are then shown in the alarm and monitoring

system.

2014

Irregular Operation

Loading...

Loading...