Operation

1132−1/A1

Winterthur Gas & Diesel Ltd.

1/ 1

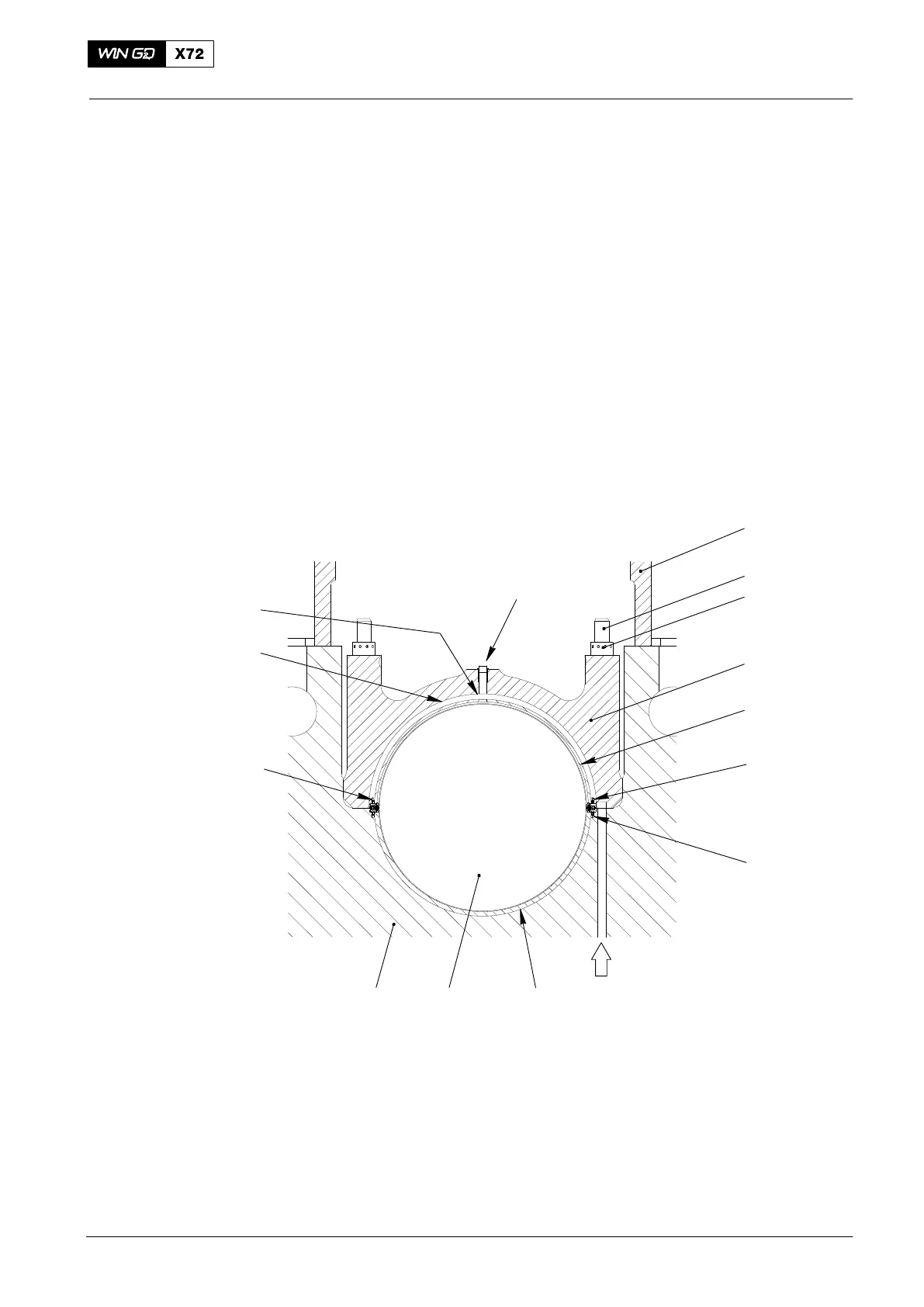

Main Bearing

1. General

The main bearing has a bottom bearing shell (7, Fig. 1) and a top bearing shell (5).

The bottom main bearing shell (7) is is installed in the bearing girder (9) of the

bedplate and the top main bearing shell (5) in the bearing cover (4). The screws (6)

engage and hold the top bearing shell and bottom bearing shell in position.

The spring dowel pin (10) helps to get the bearing cover (4) in position.

The elastic studs (2) have a non-hardening locking compound applied to the threads.

Hydraulic tension is applied to the elastic studs during the install procedure. The

round nuts (3) keep the bearing cover (4) against the bearing girder (9).

2. Lubrication

Oil flows from the bedplate through the oil inlet (OI) to the main bearings. The oil flows

through the grooves (OG) and bores (OB) to the running surface of the main bearing.

WCH01197

OI

OB

OG

10

9

8

7

6

6

5

4

2

3

1

11

Fig. 1: Main Bearing

1 Column 9 Bearing girder

2 Elastic stud 10 Spring dowel pin

3 Round nut 11 Plug

4 Bearing cover

5 Top main bearing shell

6 Screw OI Oil inlet

7 Bottom main bearing shell OG Oil groove

8 Crankshaft OB Oil bore

2014

Loading...

Loading...