Operation

3140−1/A1

Winterthur Gas & Diesel Ltd.

1/ 2

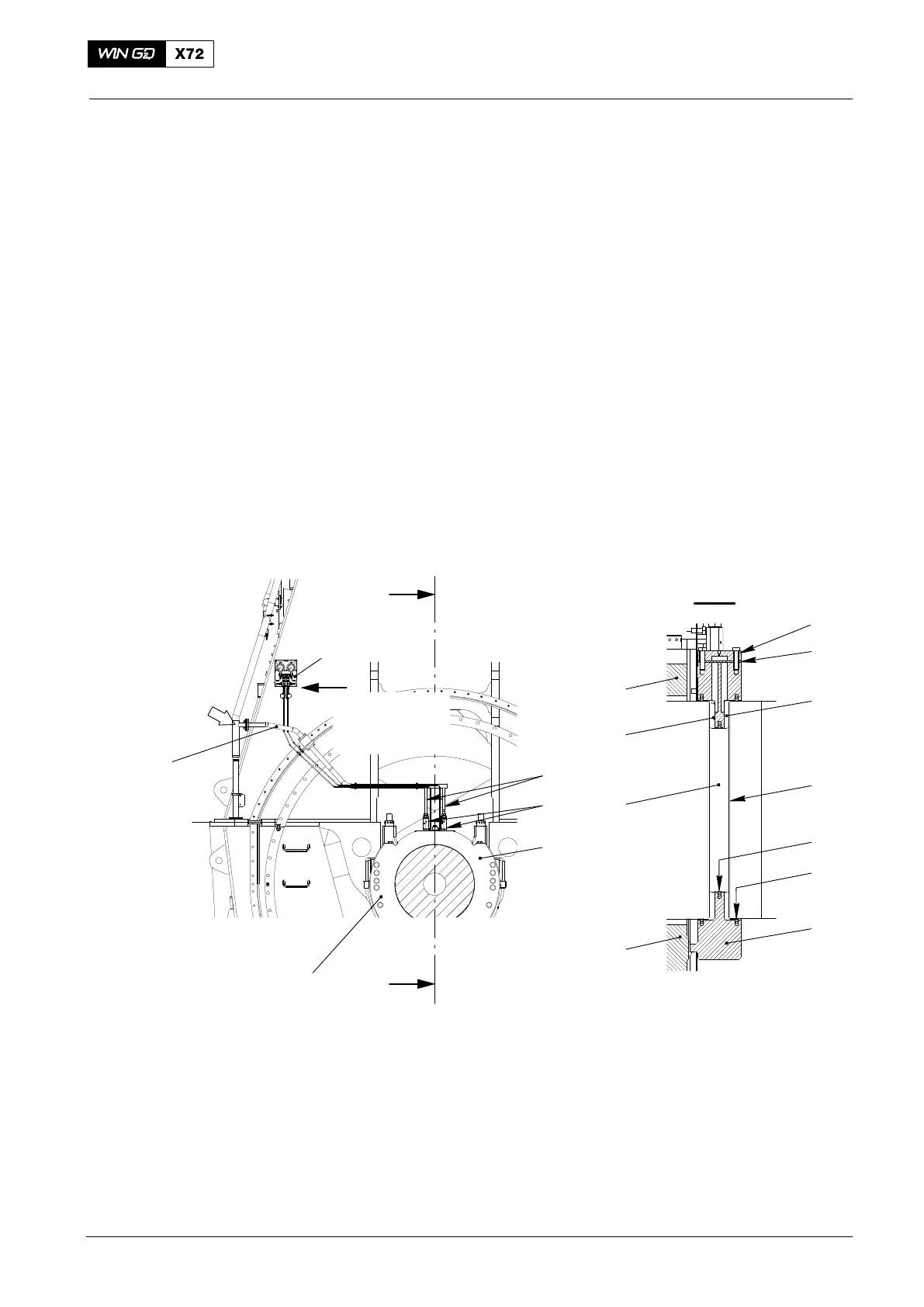

Axial Damper

1. General

The engine has a built-in axial damper. The function of the axial damper is to

decrease the axial vibrations.

The axial damper includes a top cylinder half (3, Fig. 1) and a bottom cylinder half (4)

attached with bolts to the last bearing girder.

2. Function

Bearing oil flows from the oil inlet (OI) through the oil pipe (5) into the two inlet pipes

(1). The bearing oil then flows through the non-return valves (2) into the groove in the

crankshaft (10) (i.e. into the annular spaces (9) on each side of the middle part of the

cylinder halves (3) and (4)).

Most of the oil can only flow through the pressure reducing nozzle (7) from one

annular space (9) to the other when the crankshaft turns.

The remaining oil drains because of the radial and axial clearances of the sealing

rings (11) and (12) and the vent bore in the pressure reducing nozzle (7).

Note: Do not operate the engine when there is no oil supply to the axial damper.

7

8

10

9

9

15

11

12

13

14

16

WCH01218

I - I

OI

I

I

5

6

1

2

3

4

WCH01218

II

For View II

see Fig. 2

Fig. 1: Axial Damper

1 Inlet pipes 10 Groove in crankshaft

2 Non-return valves 11 Large sealing ring

3 Top cylinder half 12 Small sealing ring

4 Bottom cylinder half 13 Vibration damper

5 Oil pipe 14 Bearing girder (part of bedplate)

6 Axial damper monitor 15 Crankshaft

7 Pressure reducing nozzle 16 Bearing cover

8 Orifice

9 Annular space OI Oil inlet

2014

Loading...

Loading...