Operation0050−1/A1

Winterthur Gas & Diesel Ltd.

2/ 2

D The exhaust gases flow from the cylinders through the exhaust valves into an

exhaust gas manifold.

D The turbocharger constantly charges the gas pressure from the manifold.

D The scavenge air from the turbocharger flows through the air cooler and water

separator into the air receiver. This air then flows through air flaps and scavenge

ports when the pistons are almost at BDC.

D At low loads, independently operated auxiliary blowers supply air to the scavenge

air space.

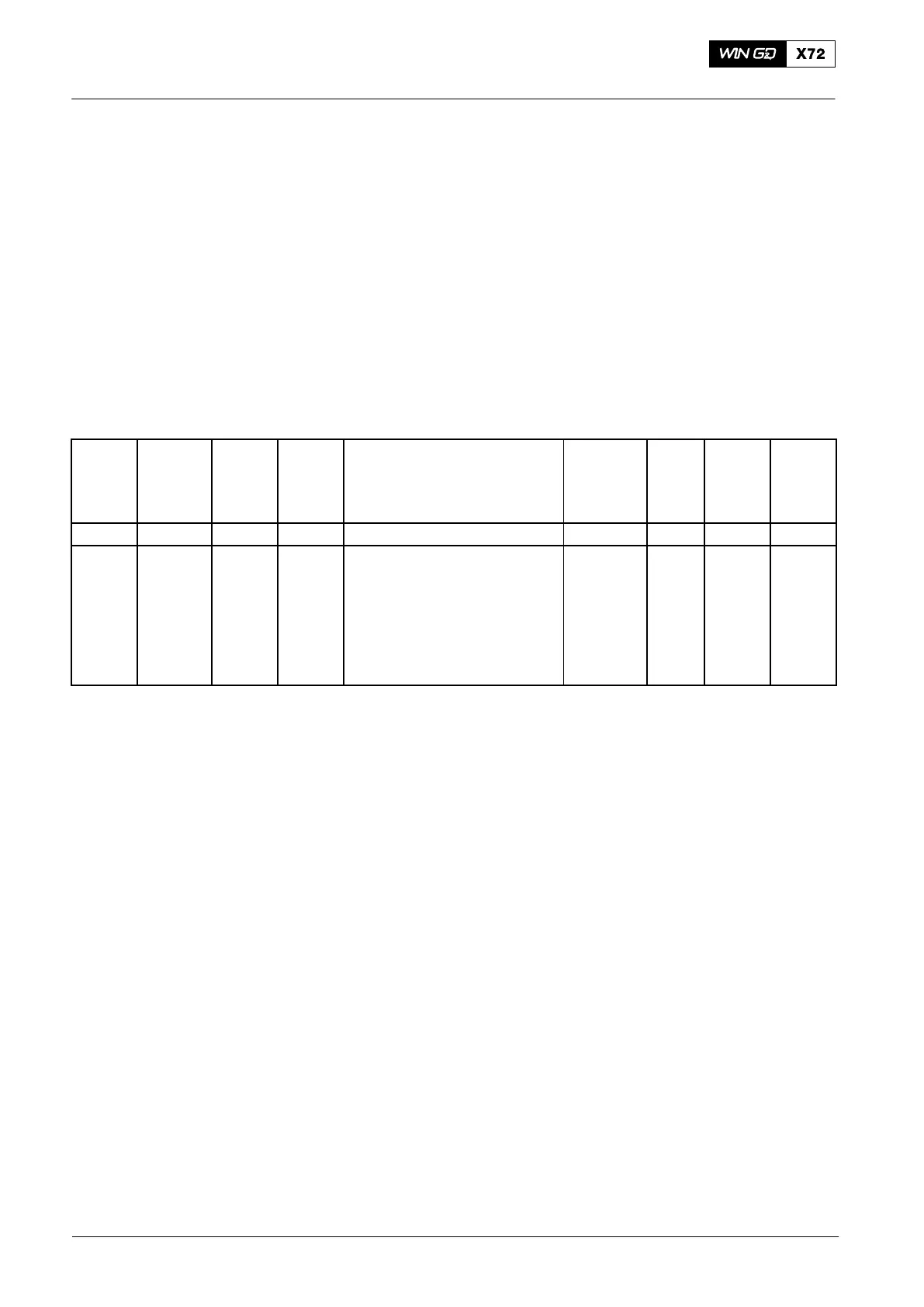

3. Standard Engine Data

The standard engine data is given in Table 1 below:

Table 1: Engine Data

Bore /

Stroke

Rating

Field

Corners

1)

Speed

n

Engine

Power

P

Specific Fuel Consumption

+5% Tolerance

100% P

2)

Standard Tuning

Number of

Cylinders

Mean

Piston

Speed

Mean

Effective

Pressure

Firing

Pressure

Guide

Values

3)

mm RPM kW/cyl g/kWh m/s bar bar

720

3086

R1+

R2+

R1

R2

R3

R4

89

89

84

84

66

66

3610

2700

3610

2700

2840

2120

167

161

168

161

168

161

4 to 8 9.2

9.2

8.6

8.6

6.8

6.8

19.4

14.5

20.5

15.4

20.5

15.4

168

168

168

168

168

168

1) R1+ to R4: Corner points of the field of permitted engine ratings.

2) For the nett calorific value 42.7 MJ/kg (10,200 kcal/kg) and ISO standard

conditions:

D Total barometric pressure: 1.0 bar

D Suction air temperature: 25° C

D Water temperature − scavenge air cooling: 25° C

D The fuel consumption values in g/kWh are the standard values

D For the SFC values of Delta tuning and Low load tuning, refer to the last

version of WinGTD

3) The firing pressure on an engine can be lower that the guide value given in the

table above.

2016−11

Short Description of the Engine

Loading...

Loading...