Operation7218−3/A1

Winterthur Gas & Diesel Ltd.

6/ 6

4. Blending on Board

You can use the Wärtsilä Blending on Board (BoB) system to adjust the BN of the

cylinder lubricating oil.

The system oil is used as a base oil and the correct additive package is added to

make an applicable cylinder lubricating oil. The BoB system gives the best results

related to the applicable neutralization and detergency properties of the cylinder

lubricating oil.

You can make different BN lubricating oils on board. With an applicable cylinder

lubricating oil it is not necessary to adjust the feed rate to different operation modes

(i.e. the base feed rate is not changed, but the cylinder oil BN is adjusted).

Use the BoB system together with an on-board monitoring system for the PU drain oil

(e.g. SEA-MateE B2000 blender combined with the SEA-MateE M2000 XRF

analyzer) to make a lubricating oil that has the correct BN. The correct BN improves

the corrosion protection, and the properties to clean the lubricating oil.

The BoB system is applicable for vessels that operate on a wide range of different

fuels (related to the fuel sulfur content) and operation modes.

As a general recommendation, refer to the data given in Table 1, but, adjust the

values as a function of the engine performance for each engine. For more data,

speak to or send a message to Wärtsilä Services Switzerland Ltd.

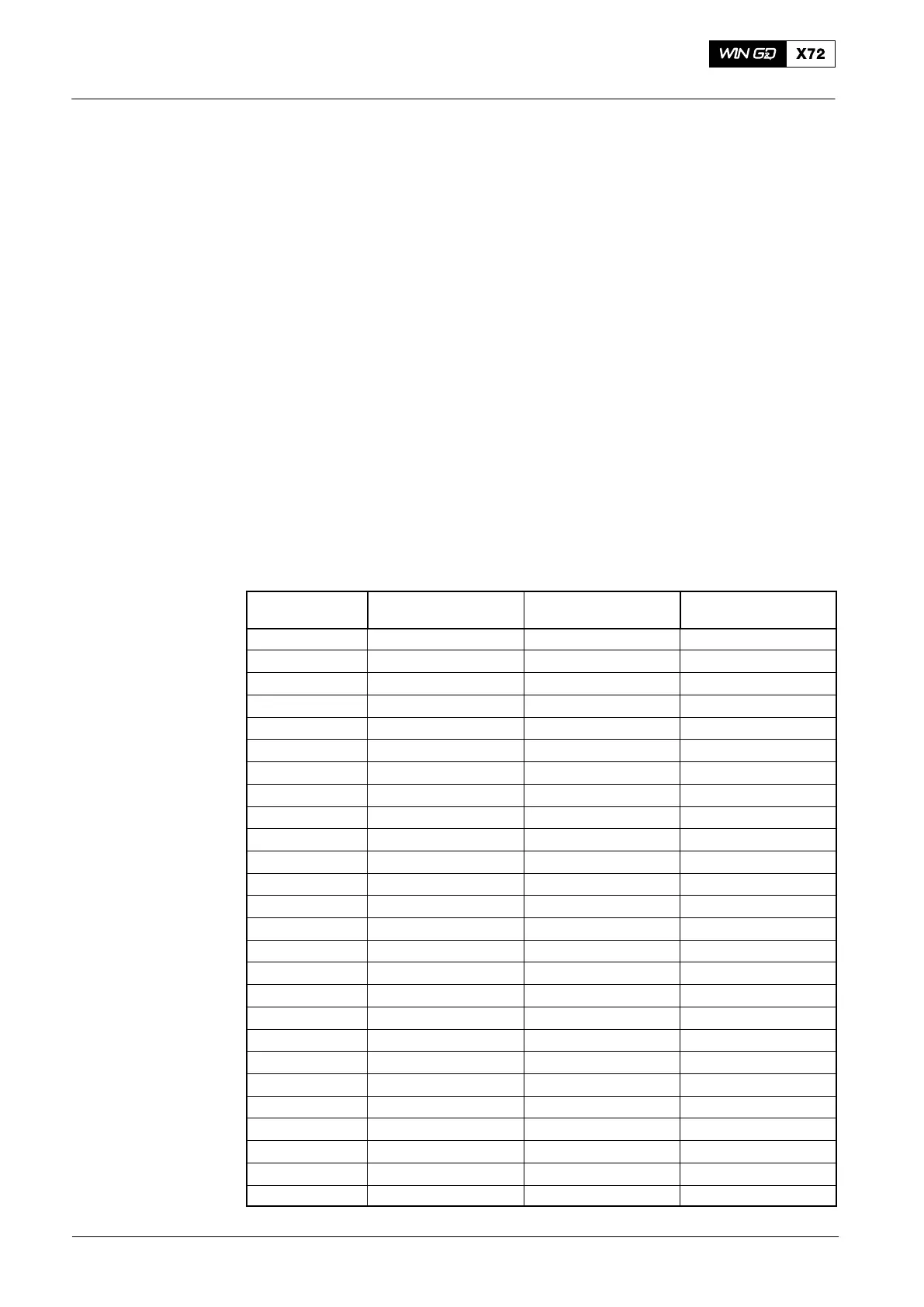

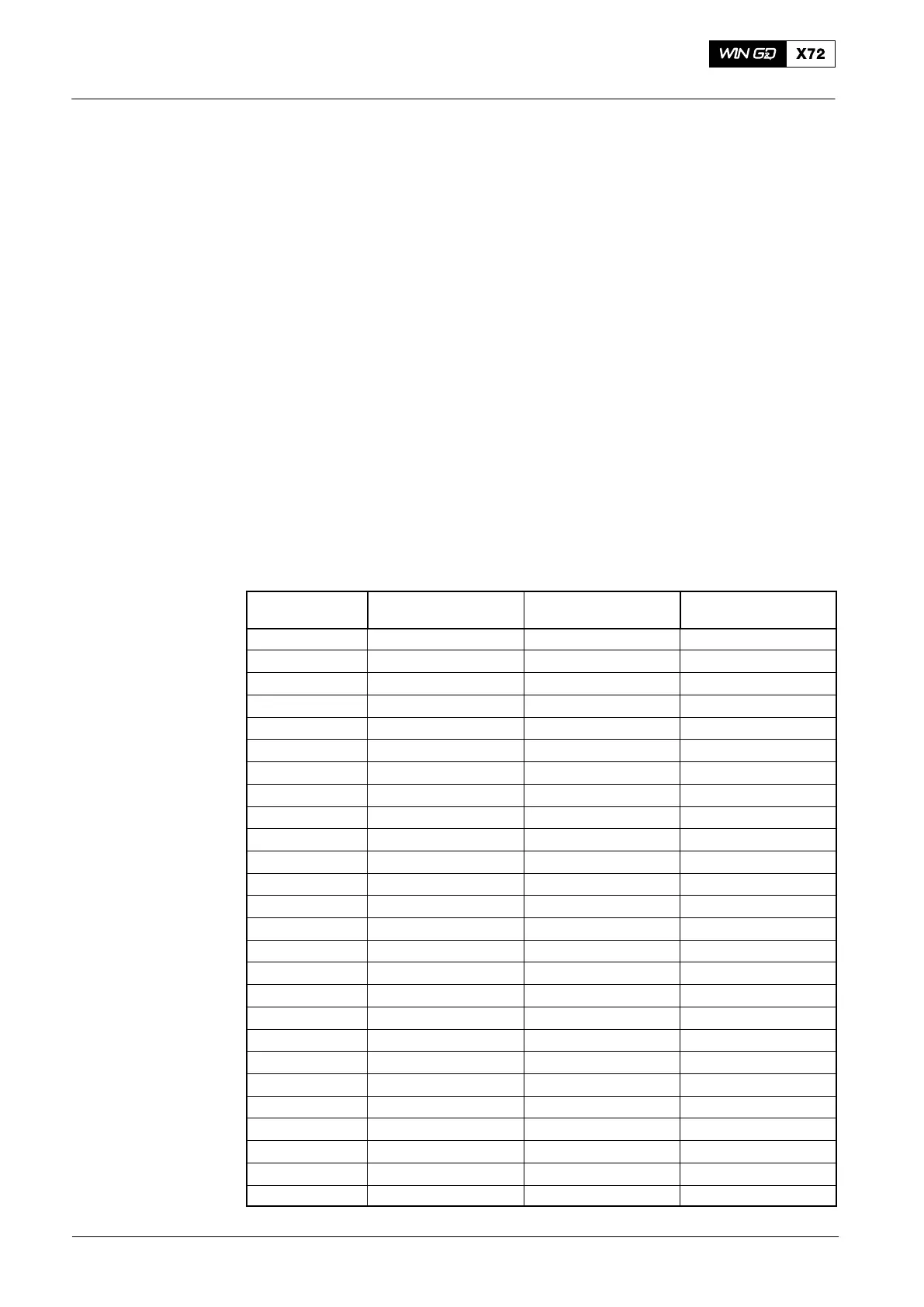

Table 1: BN Values Related to Sulfur Content for a Base Feed Rate of 0.8 g/kWh

Sulfur

Content [%]

Usual Operation

(above 60% CMCR)

Low Load Operation

(below 60% CMCR)

Safeguard Operation

1.0 40 40 40

1.1 40 40 40

1.2 40 40 40

1.3 40 40 40

1.4 40 40 40

1.5 40 40 50

1.6 50 50 50

1.7 50 50 50

1.8 50 50 60

1.9 50 50 60

2.0 50 50 60

2.1 50 50 60

2.2 50 70 60

2.3 50 70 70

2.4 50 70 70

2.5 50 70 70

2.6 50 70 70

2.7 50 70 80

2.8 50 70 80

2.9 51 72 80

3.0 53 75 90

3.1 55 77 90

3.2 57 80 90

3.3 59 82 100

3.4 61 85 100

3.5 63 87 100

2015-12

Feed Rate − Adjustment

Loading...

Loading...