SmartPAC 2 User Manual 1126700

Preventive Maintenance Monitor A-3

1

For SmartPAC (without WPC), “run hours” refers to the length of time that SmartPAC is “on”. For SmartPAC with

WPC, it means how long the motor is “on”. (The version of SmartPAC that you currently have is without WPC. Con-

tact Wintriss Controls if you require WPC.)

2

Ch. cycles 1 through 16 can be used only if you have a 16-channel ProCamPAC. Only ch. cycles 1 through 8 can be

used for an 8-channel configuration.

3

These are only available if you have SmartPAC with WPC and if you have wired and assigned press functions to the

user-definable inputs. (The version of SmartPAC that you currently have is without WPC. Contact Wintriss Controls

if you require WPC.)

4

“Press overload” is only available with the AutoSetPAC option.

Installing the PM Monitor

For New Systems from the Factory

If you purchased a SmartPAC 2 system with the PM Monitor pre-installed at the factory, you

can proceed directly to Using the PM Monitor in Initialization Mode, page A-4.

For Existing Systems

If you ordered the PM Monitor options separately (in other words, if you already had a

SmartPAC 2, and you were just adding the PM option), you must first physically upgrade

your SmartPAC 2 system for compatibility. To upgrade your SmartPAC 2 firmware, refer to

Appendix B.

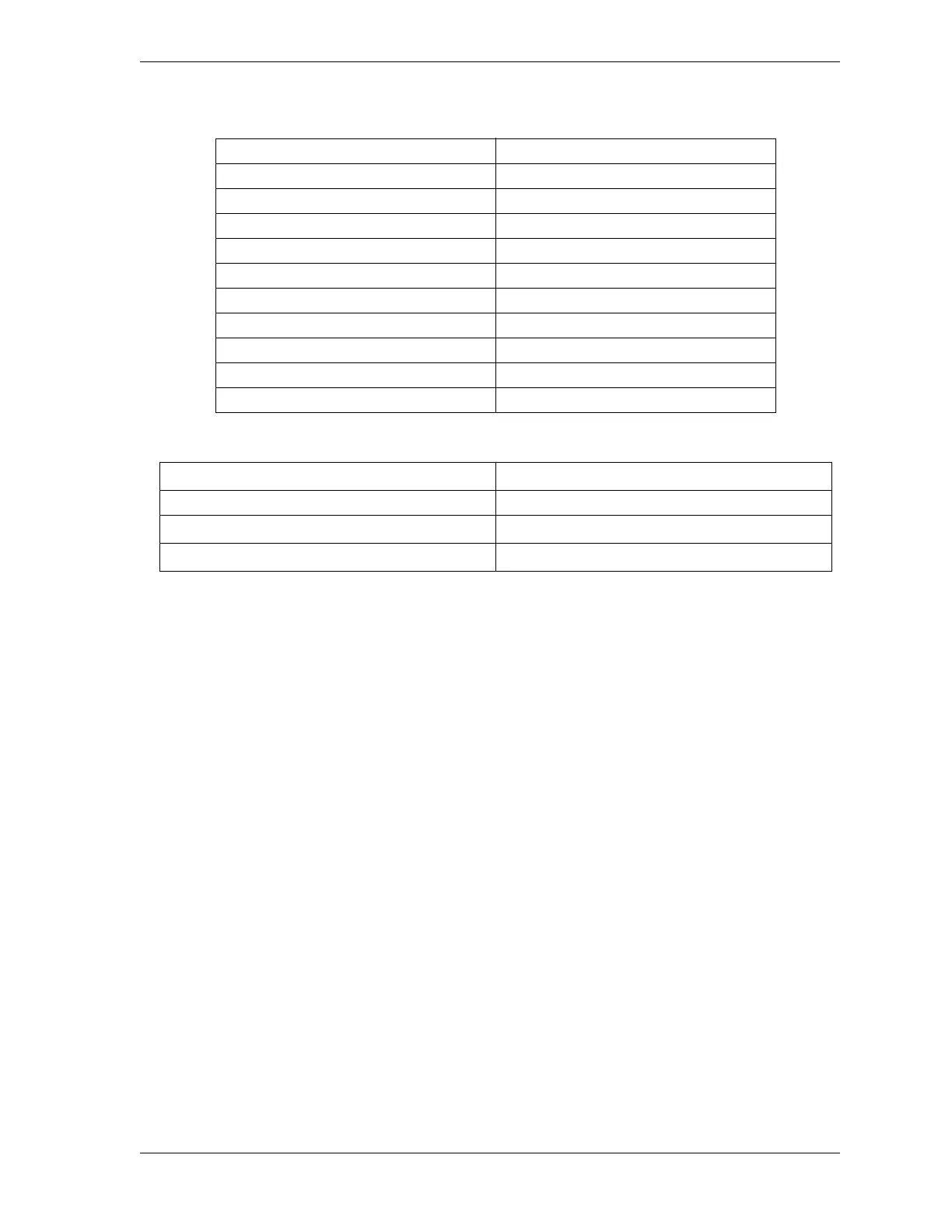

Table A-1. Preventive Maintenance Items

air rotary seals back shaft bearing (1 through 4)

brake bull gear

clutch valve conveyor (1 through 6)

counterbalance system drive belts

DSV feeder

flywheel bearing gibs

lube filter lube motor

lube system main bearing (1 through 4)

main motor oil level

pilot solenoid pinion key

pitman bearing (1 through 4) “Custom” name

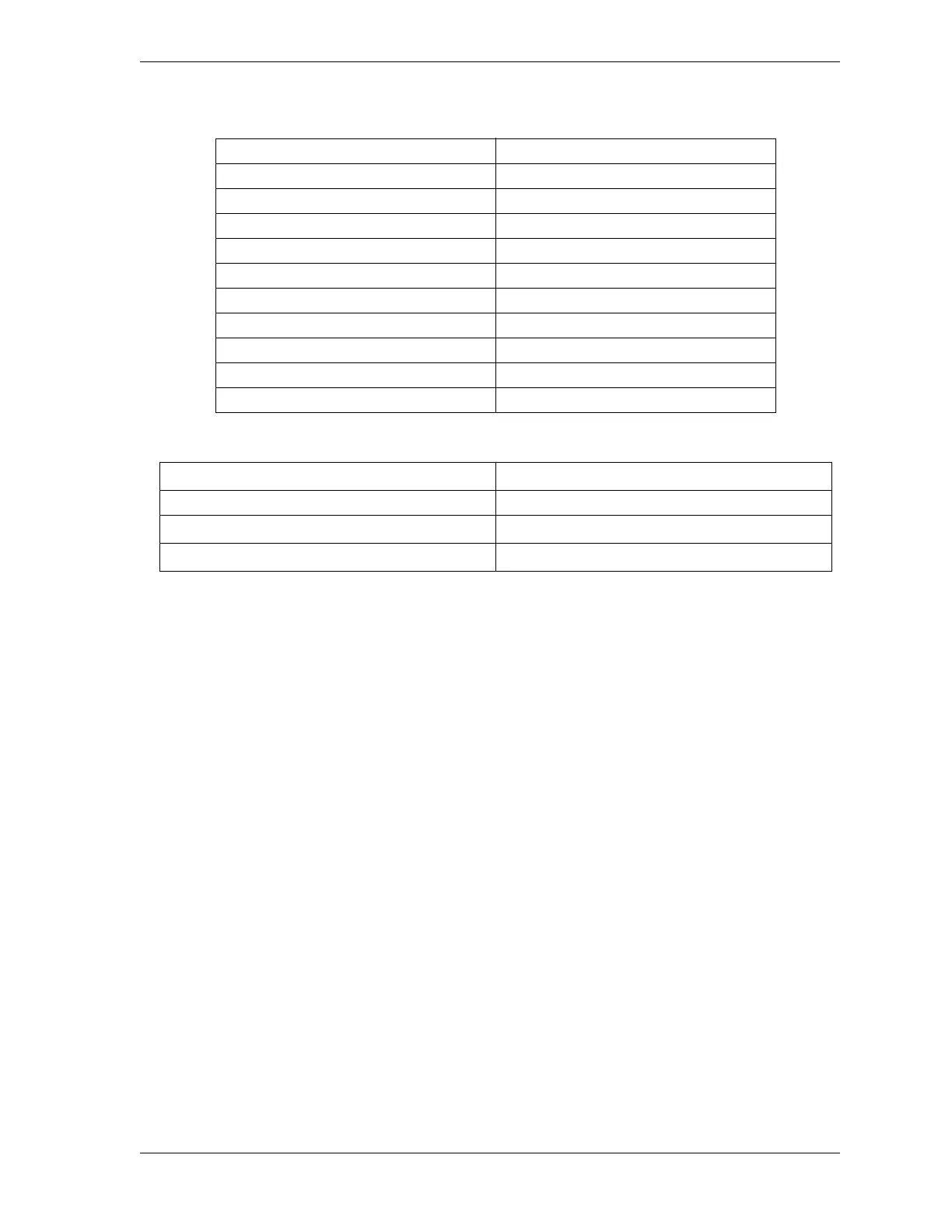

Table A-2. PM Tracking Units

run hours

1

days

weeks months

die changes

ch. cycles (1 through 16)

2

WPC press control faults, F50-F58

3

press overloads

4

Loading...

Loading...