6 Basic System Operation

6.3.1 Drawings (DWGs)

6-8

6.3 User Programs

This section explains the basic operation of the user program. The MP2100/MP2100M’s user programs include

ladder program and motion program. For details, refer to the following manuals.

• Machine Controller MP900 Series User’s Manual Ladder Programming

(Manual No.: SIEZ-C887-1.2)

• Machine Controller MP

User’s Manual Motion Programming

(Manual No.: SIEZ-C887-1.3)

• Machine Controller MP900 Series New Ladder Editor Programming Manual

(Manual No.: SIE-C887-13.1)

• Machine Controller MP900 Series New Ladder Editor User’s Manual

(Manual No.: SIE-C887-13.2)

6.3.1 Drawings (DWGs)

User programs are managed in units of programming called drawings. Each drawing is identified by a drawing

number (DWG No.). These drawings serve as the basis of user programs.

The drawings include parent drawings, child drawings, grandchild drawings, and operation error drawings.

Besides the drawings, there are functions that can be freely called from each drawing.

• Parent Drawings

Parent drawings are executed automatically by the system program when the execution condition is

established. See the following table for execution conditions.

• Child Drawings

Child drawings are executed by being called from a parent drawing using the SEE instruction.

• Grandchild Drawings

Grandchild drawings are executed by being called from a child drawing using the SEE instruction.

• Operation Error Drawings

Operation error drawings are executed automatically by the system program when an operation error

occurs.

• Functions

Functions are executed by being called from a parent, child, or grandchild drawing using the FSTART

instruction.

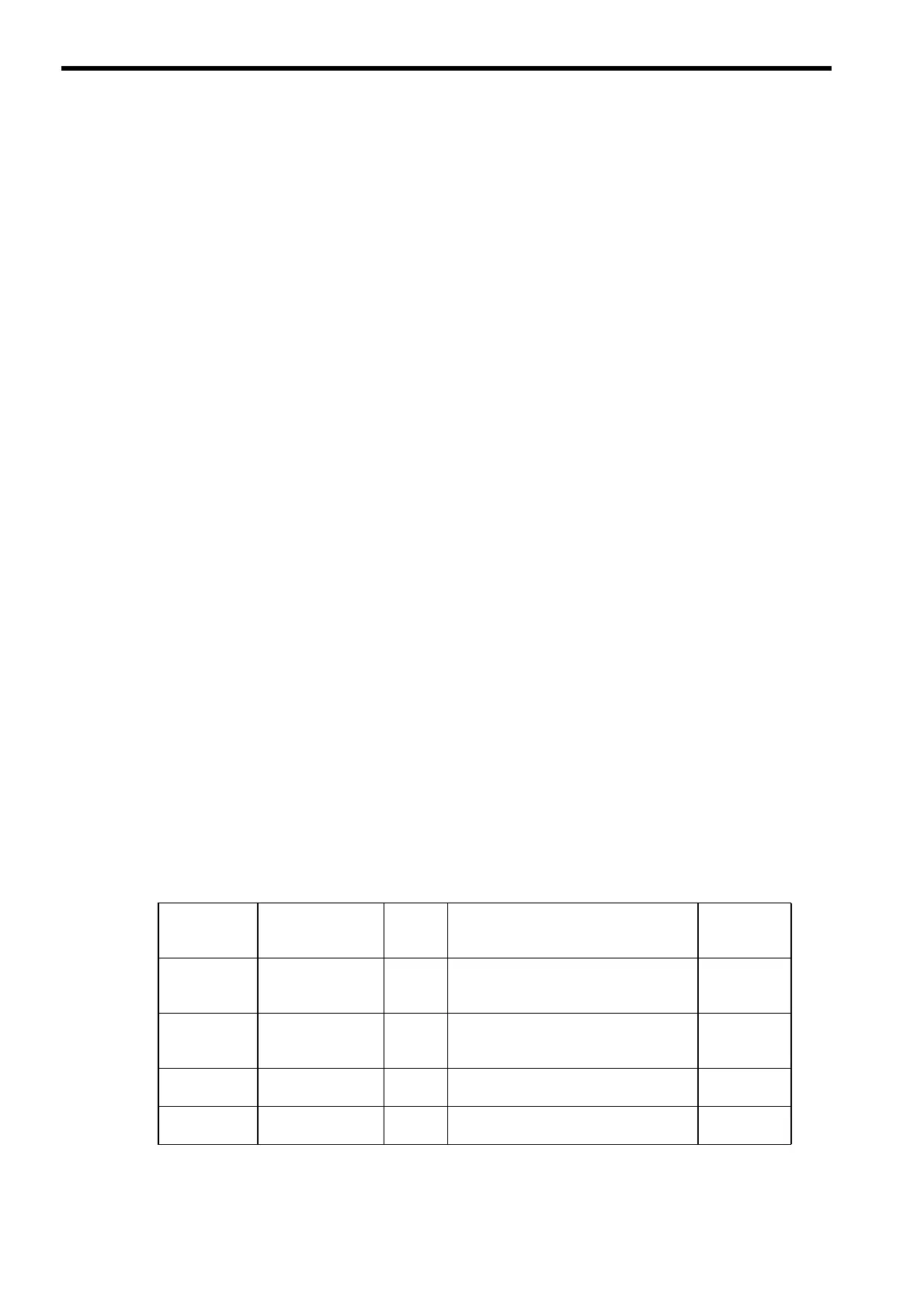

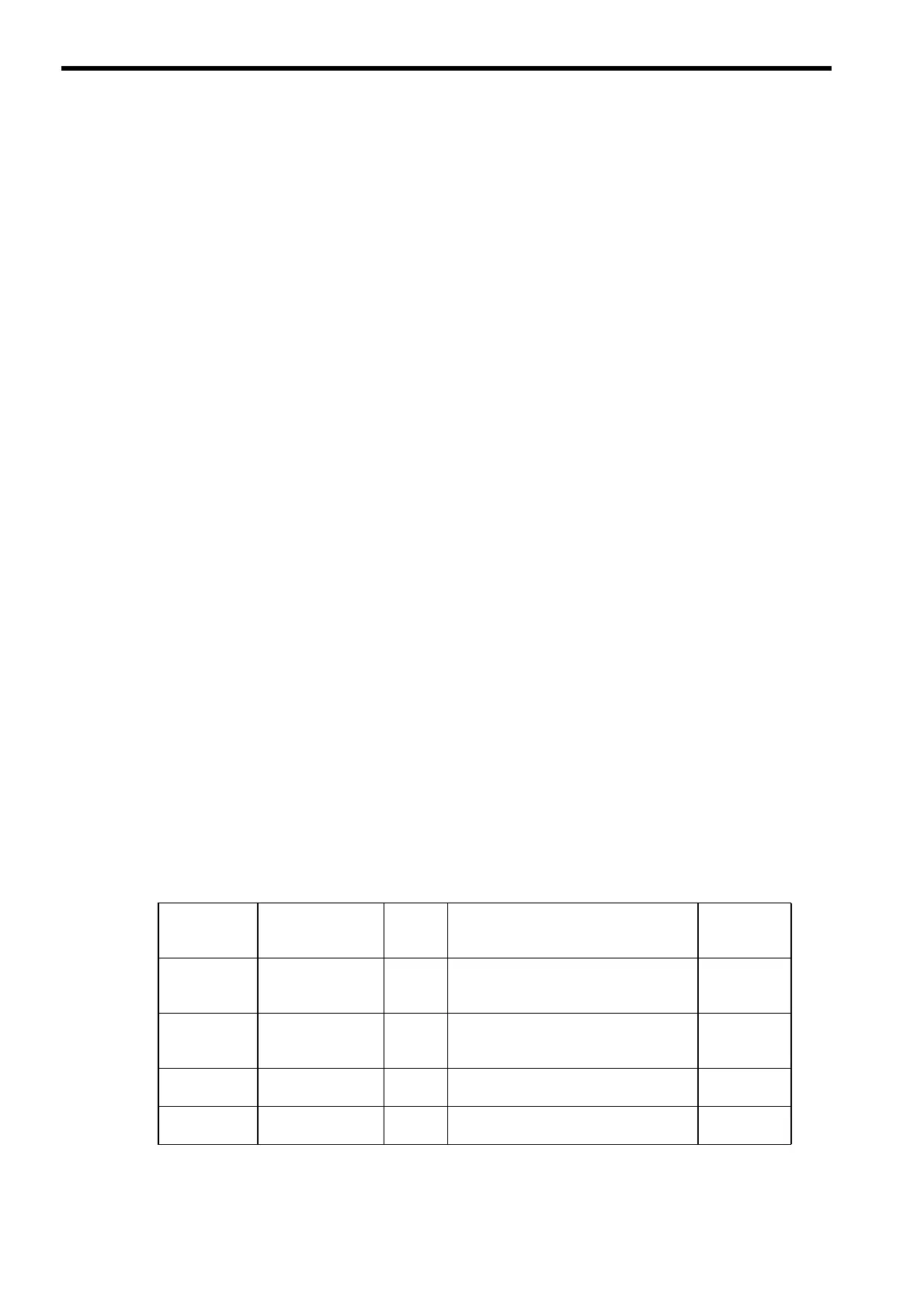

• Types and Priority Levels of Drawings

Drawings are classified by the first character of the drawing number (A, I, H, L) according to the purpose of

the process. The priority levels and execution conditions are as shown in the following table.

Type of

Parent

Drawing

Role of Drawing

Priority

Level

Execution Condition

Number of

Drawings

DWG.A

(drawing A)

Startup process

1

Started when power is turned ON (exe-

cuted once only when the power is turned

ON).

64

DWG.I

(drawing I)

Interrupt process

2

Executed by external interrupts, such as

Optional Module DI interrupts or counter

interrupts.

64

DWG.H

(drawing H)

High-speed scan

process

3

Started at a fixed interval (executed during

each high-speed scan).

200

DWG.L

(drawing L)

Low-speed scan

process

4

Started at a fixed interval (executed during

each low-speed scan).

500

Loading...

Loading...