1756-6.5.3 - December 1999

Installing the ControlNet Network 2-7

Important:You can install or remove a module while chassis power is

applied.

Connecting the ControlNet

Network

Connect the 1756-CNB modules and the 1784-KTCX15 communication

interface card to the ControlNet network using taps (1786-TPS, -TPYS,

-TPR, -TPYR).

1. Remove and save the dust cap(s) from the ControlNet tap(s)

.

ATTENTION: When you insert or remove a module

while backplane power is on, an electrical arc may

occur. An electrical arc can cause personal injury or

property damage by:

• sending an erroneous signal to your system’s field

devices causing unintended machine motion or loss

of process control.

• causing an explosion in a hazardous environment.

Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating connectors.

Worn contacts may create electrical resistance that can

affect module operation.

When connecting a

ControlNet network, you

should also refer to the

ControlNet Cable System

Planning and Installation

Manual, publication number

1786-6.2.1.

!

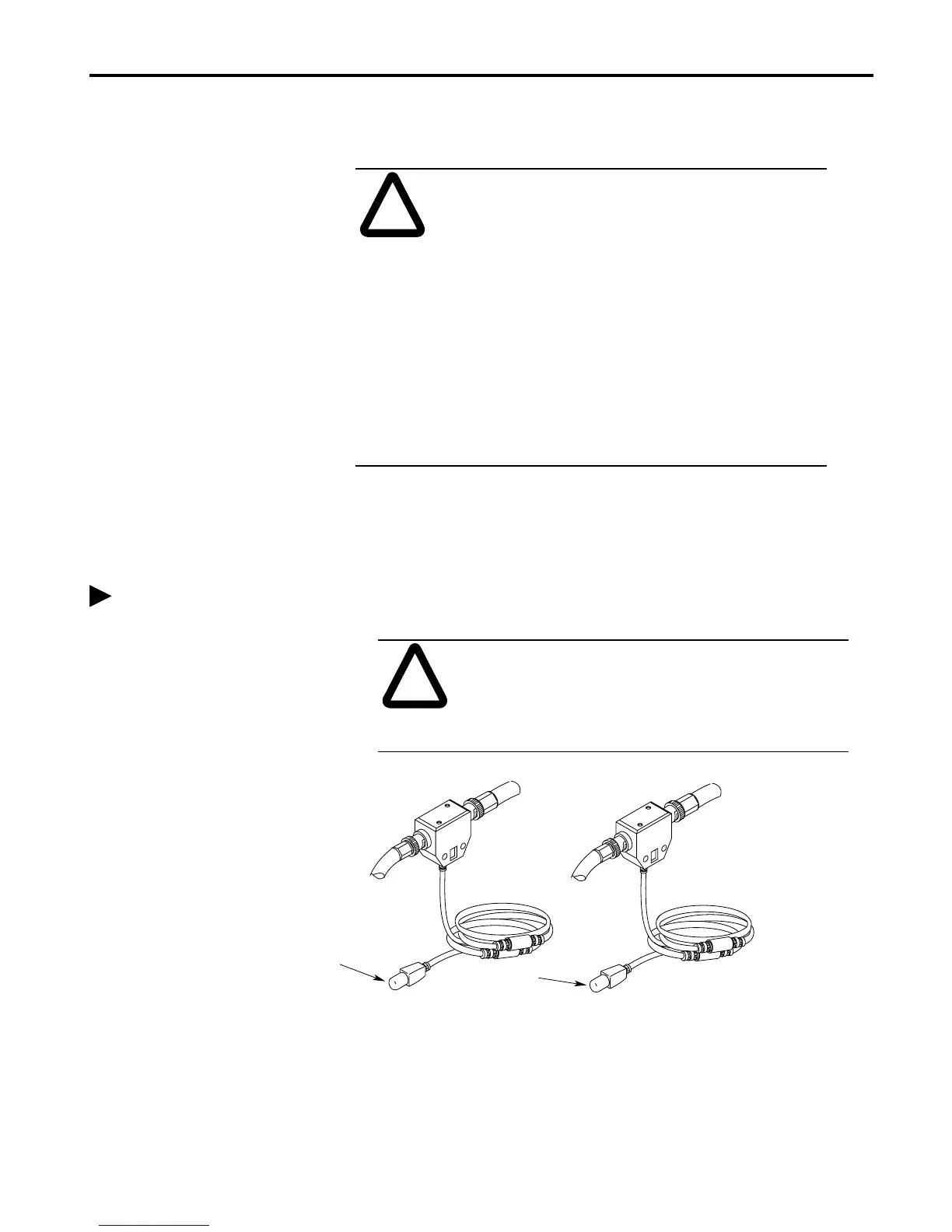

ATTENTION: Do not allow any metal portions of the

tap to contact any conductive material. If you

disconnect the tap from the module, place the dust cap

back on the connector to prevent the connector from

accidentally contacting a metallic grounded surface.

segment 1

segment 2

dust cap

dust cap

1756-CNB - segment 1

1756-CNBR - segments 1 and 2

Loading...

Loading...