Chapter 5 Parameter Introductions

150

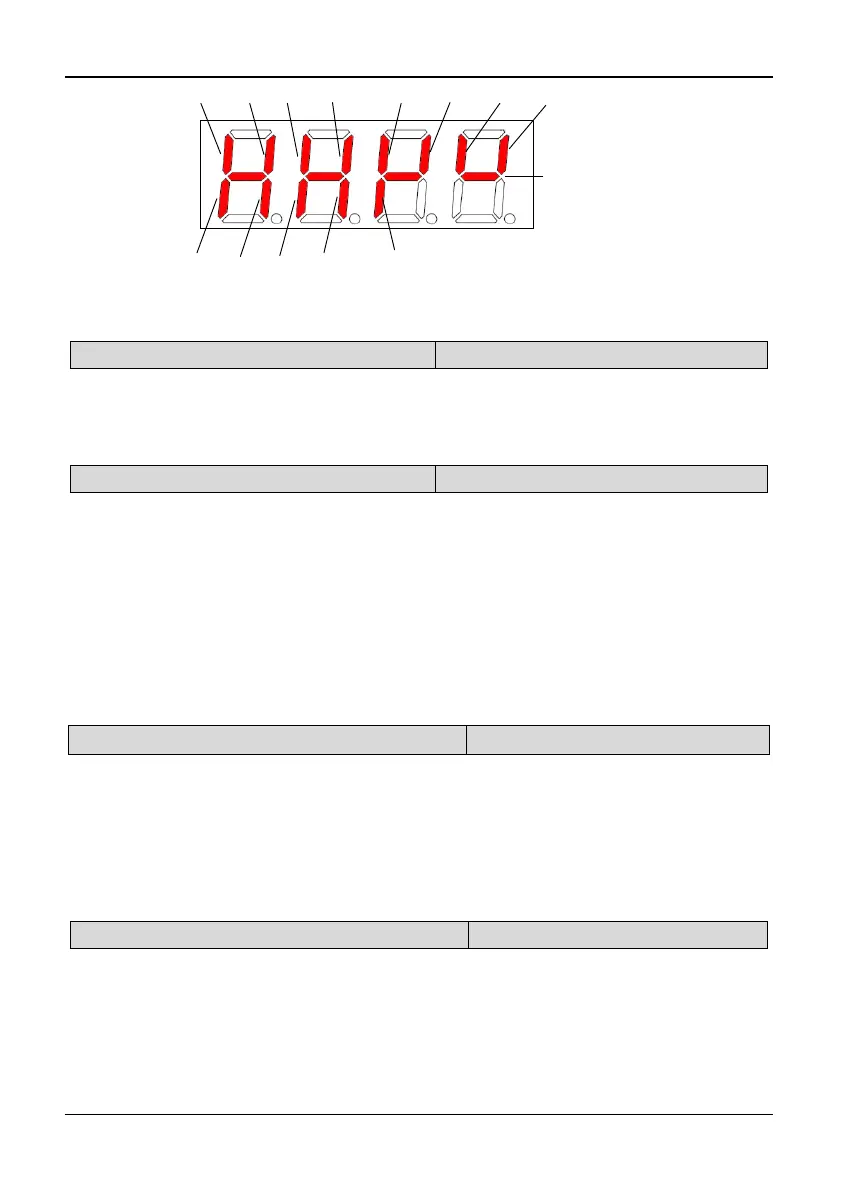

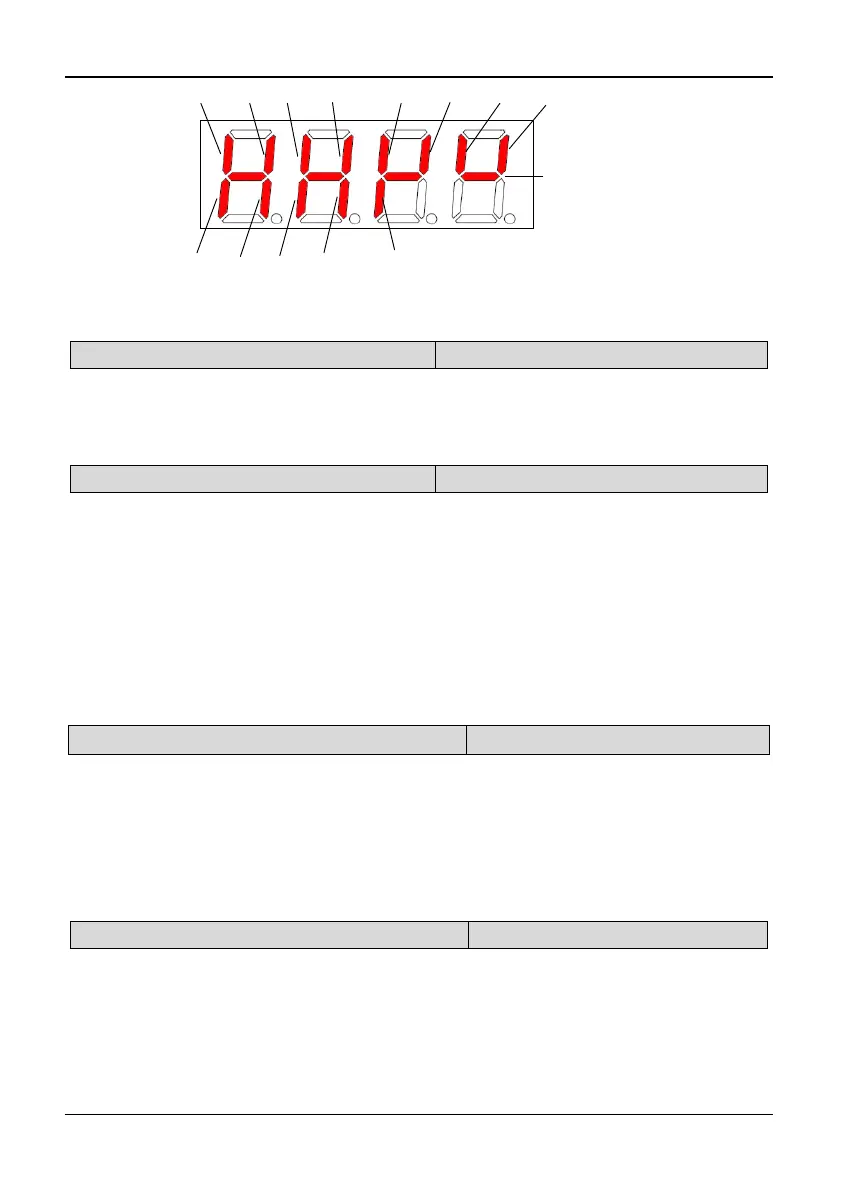

X3 X5 X7 X8X6X4X2X1

Y1 Relay1

TA/TB/TC

Relay2

BRA/BRB/BRC

Y2DO

Always on

Fig. 5-12-2Terminal status diagram of 35R5GB/37R5PB~3500G

PC.19 Actual length (m)

Range: 0,1【0】

0: No display 1: Display

Note:

If PC.19 is set to 1, the actual length will be displayed in monitoring state, and all

unit indicators will be off. If it is set to 0, actual length will not be displayed.

PC.20 Power on display

Range: 1~19【1】

PC.20 is used to set the first display parameter at power on. The setting value is from

1 to 19, corresponding to PC.01~PC.19 respectively. If the display property of the

first display parameter is 0 (PC. XX=0, XX is the value of PC.20), the keyboard will

search from the current settings of PC.20 (PC. XX) to the last (PC.19) and then back

to go on search from 1 (PC.01) to the value of PC.20, until the setting value is 1. In

addition, keep this display object as the first monitoring object.

Power on display selection will take a priority display of PC.01 ~ PC.19 absolutely;

and only takes affect at the boot time. When there is an error, an alarm or a

communication CALL to be displayed, the error will display at first, then the alarm or

the CALL, and the power on display selection will not work.

PC.21 Rotating speed display coefficient

Range: 0.1~999.9%【100.0%】

Note:

PC.21 (Rotating Speed display coefficient) is used to correct the bias of displayed

rotating speed and it has no influence on actual speed.

Rotate speed = actual rotate speed × PC.21 (PG)

Rotate speed=120 × Operating Frequency ÷ PA.00 × PC.21 (non-PG)

Reference speed= PID reference speed × PC.21 (PG)

Reference speed=120*reference frequency÷PA.00×PC.21 (non-PG)

PC.22 Linear speed display coefficient

Range: 0.1~999.9%【100.0%】

Note:

PC.22 (Linear speed coefficient) is used to correct the bias of displayed line speed

and it has no influence on actual speed.

Linear speed = Running frequency × PC.22 (non PG)

Linear speed = rotate speed × PC.22 (PG)

Reference linear speed= reference frequency* PC.22 (non PG)

Loading...

Loading...