Chapter 5 Parameter Introductions

91

P1.11 DC injection braking current at

stop

Range: This value depends on the inverter

model【0.0%】

P1.12 DC injection braking time at stop

Range: 0.0~30.0s【0.0s】

Note:

DC injection braking is injecting DC current to motor, to let it stop quickly, and

keep the spindle of motor in standstill until finished DC injection braking

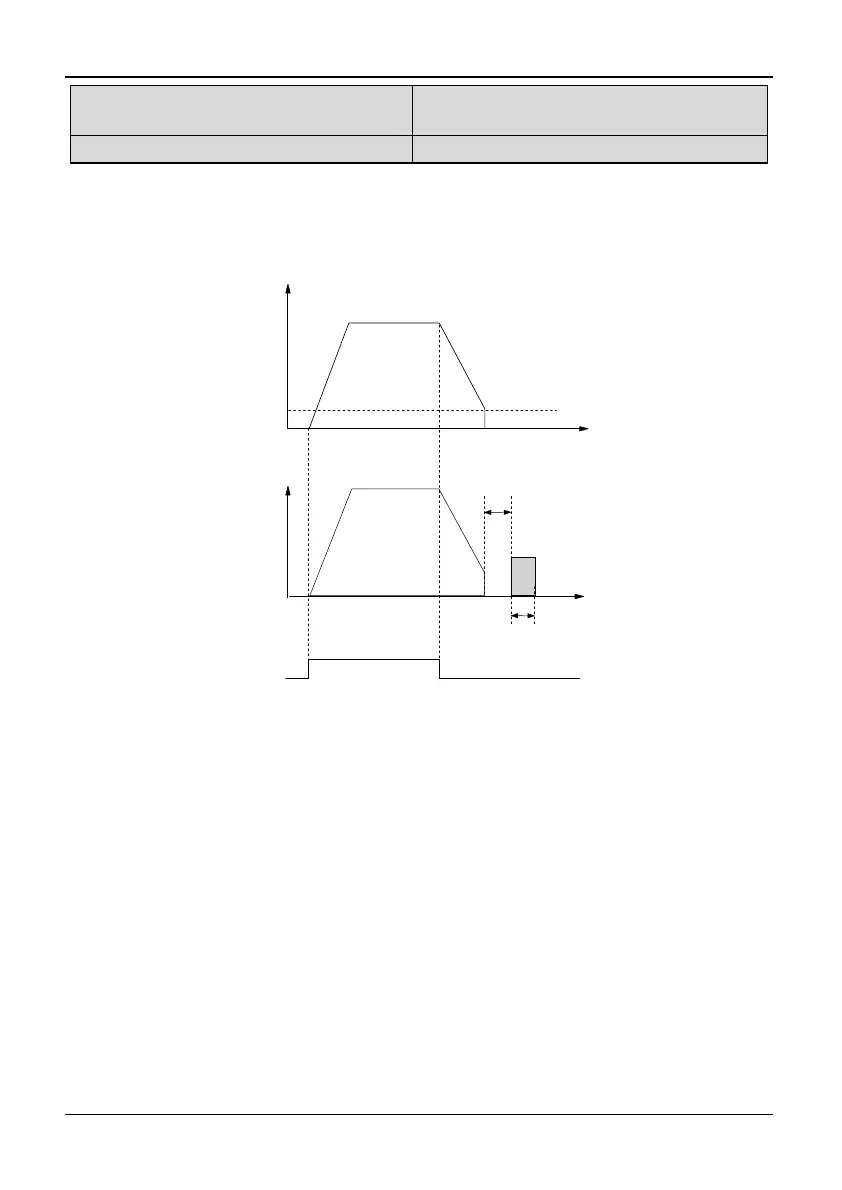

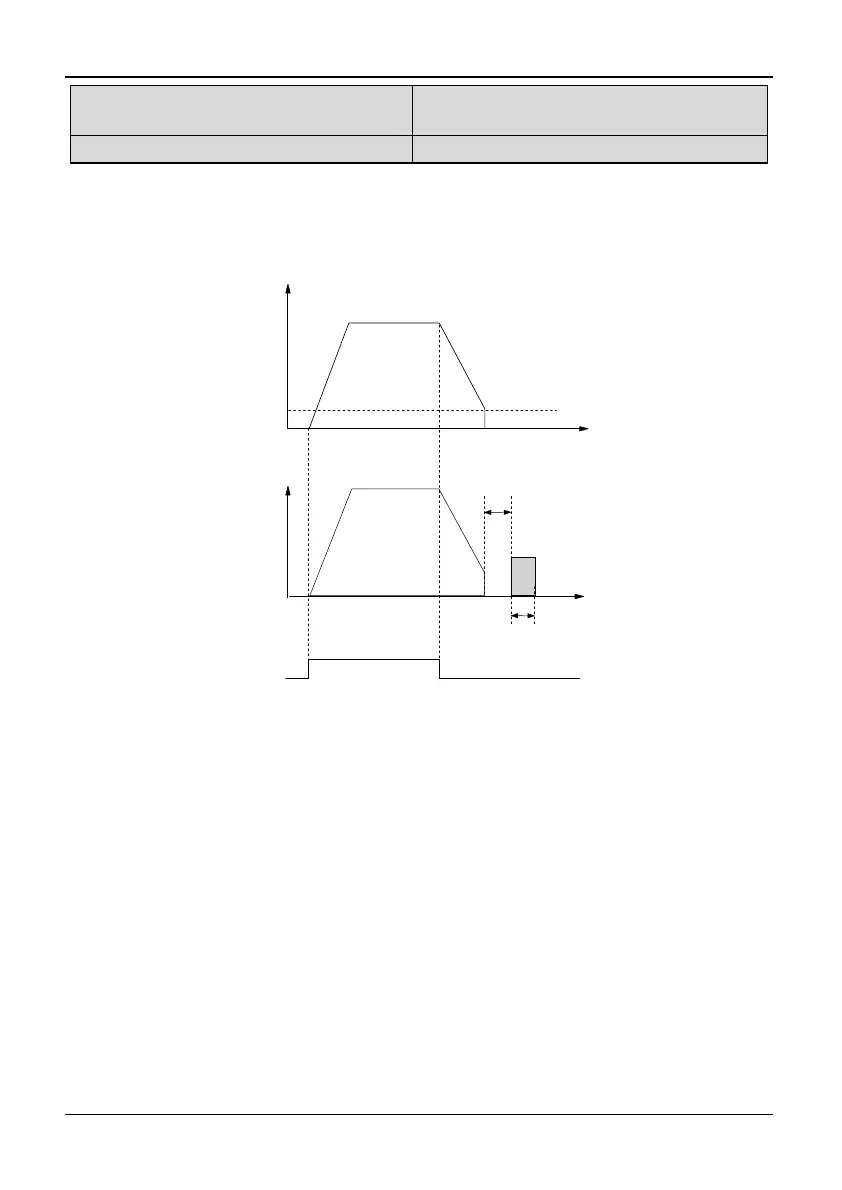

Output Freq.

DC injection braking

frequency at stop

Output Voltage

(

effective value

)

Braking

Energy

Time

Running

command

Waiting time for DC

injection braking at

stop

DC injection

braking time

Fig. 5-1-6 DC injection braking

DC injection braking frequency at stop is the frequency at which DC injection

braking action begins when the inverter in Dec-to-stop process. In the process of

constant rate deceleration, if the output frequency is at or below the “DC injection

braking frequency at stop, the DC injection braking function will startup.

DC injection braking current at stop is a relative percentage of inverter rated

current. The DC injection braking function disables when the braking time is 0.0s.

The setting range of Type G is 0.0~100.0%, and Type P is 0.0~80.0%.

DC injection braking time is the DC injection braking holding time. This time

cannot be set too long; otherwise, it will cause the inverter overheating. When the

DC injection braking time is set to zero, the DC injection braking function disables.

Tips:

This function will start up after inverter receives stop command. Usually, it is used to

improve the stop precision and not for deceleration braking in common running. If

faster stop is required, braking energy regeneration unit should be fitted, or the inverter

that has the function of brake energy regeneration should be selected.

Loading...

Loading...