Chapter6 Troubleshooting

170

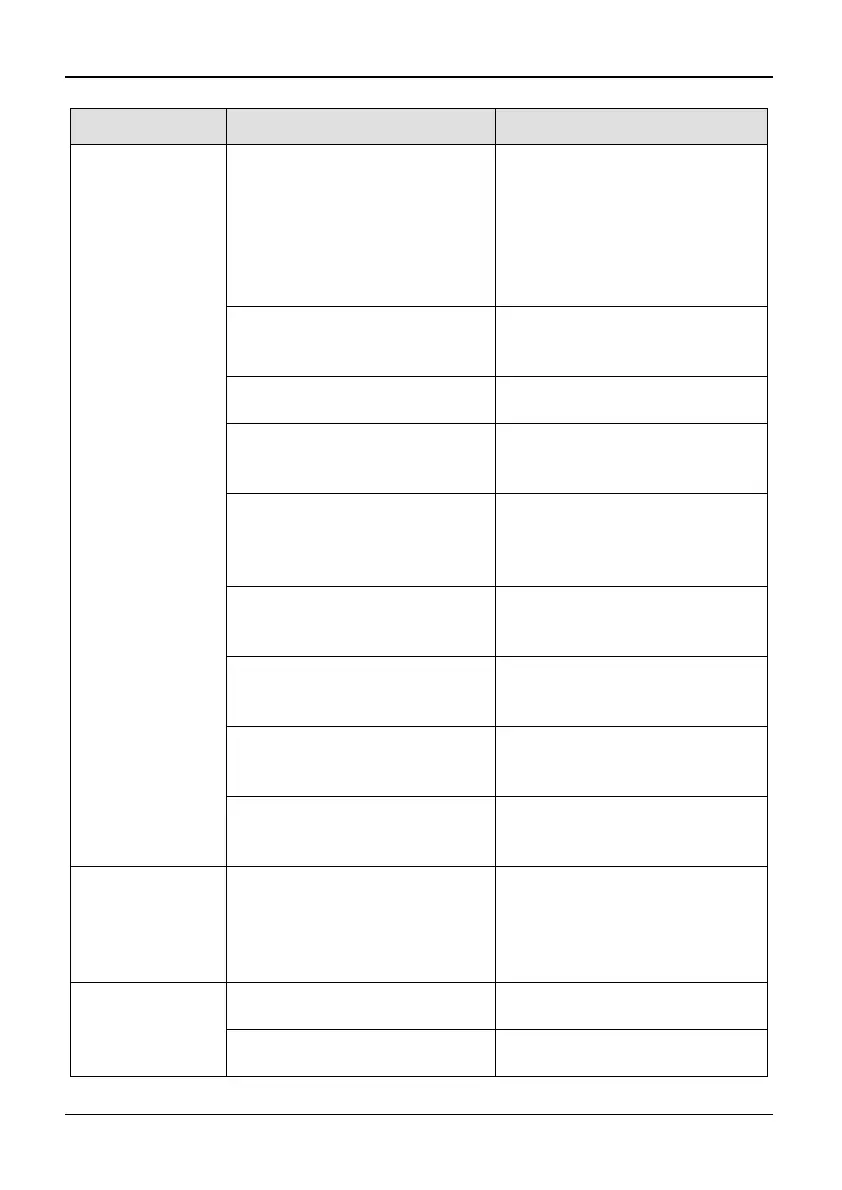

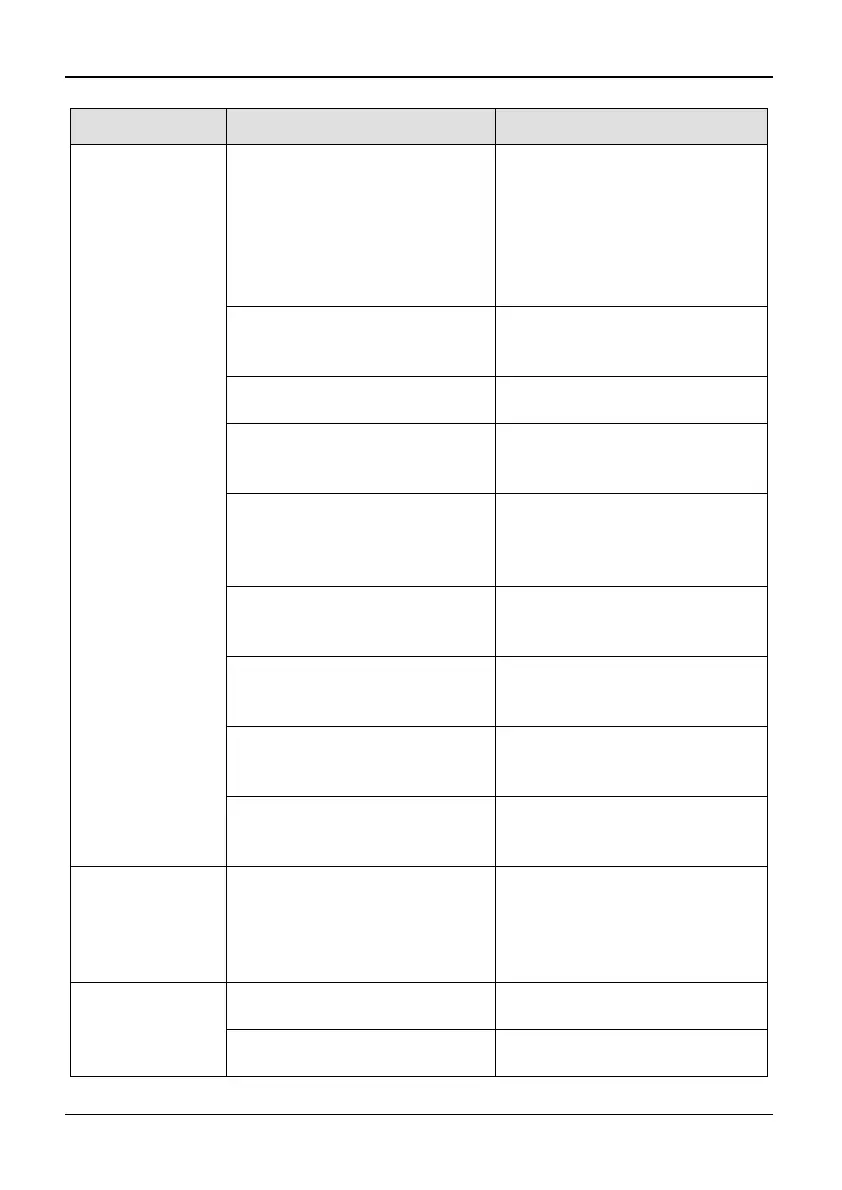

Table 6-3 Motor fault and corrective measure

Fault Content of checking Corrective measure

The motor

doesn’t work

Whether the power supply

connect to terminals R, S, T.

Whether charge LED lit

●Turn on the current

●Cut the current and then turn

on again

●Check voltage of power

supply

●Be sure the bolts fasten

terminals firmly

Use a rectifying voltmeter to

test whether the voltage of

terminals U, V, W is correct

●Cut the current and then turn

on again

Whether the motor is locked

for over loading

●Reduce the load and remove

the lock

Is there any fault code

displayed on the keyboard?

Is indicator TRIP flashing?

●Fault code referred in Table

6-1

Is there any running command

●Check whether operating

terminal connection and

connection between 24V and

PLC are firm

Whether prohibit reverse

operation setting is according

with running direction.

●Set reverse operation enable

or change the direction order

of motor

Whether terminals operating

signal cut first and then close

after fault.

●Cut terminals operating

signal first and then close

Whether frequency reference

voltage has been given by

analog input

●Check frequency reference

voltage

Whether the setting of run

command mode selection is

correct

●Select correct mode

Motor’s

rotation

direction is

contrary

Whether the connection of

terminals U, V, W is correct

●Switch the motor’s

connection of terminals U, V,

W

●Adjust parameter value of

P2.25

Motor rotate but

can’t shift

Whether the connection of

frequency circuit is correct

●Correct the connection

Whether the load is too heavy

●Reduce the load or increase

Acc/Dec time

Loading...

Loading...