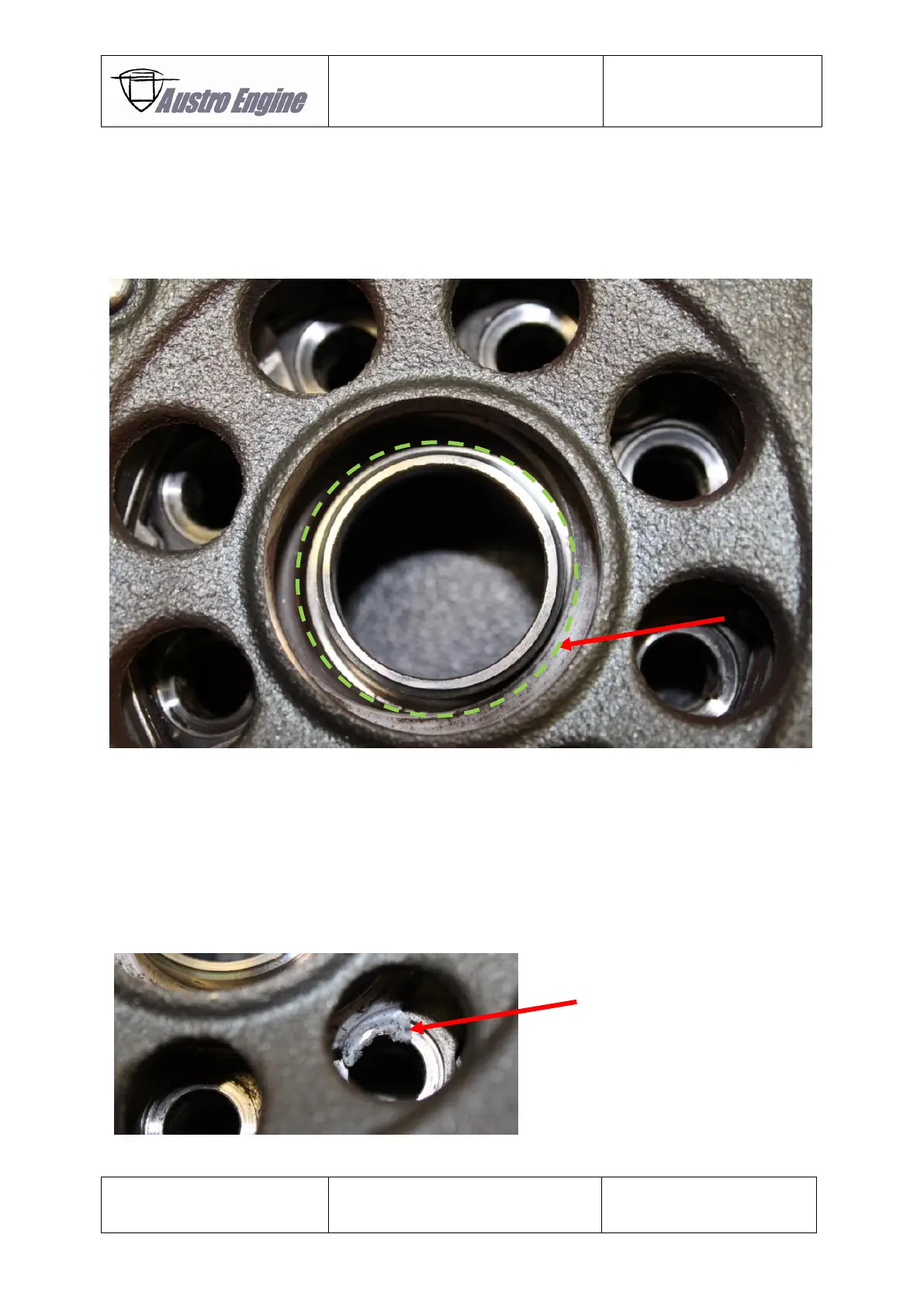

Bearing Friction Ring:

The friction ring has to be in the correct position. If the friction ring has contact to the bearing

bushing as seen in the following figure the ring has to be repositioned. Therefore lift the secondary

mass slightly thus the ring can be repositioned with a small screwdriver. The correct position is

reached when the inner diameter of the ring has approximately the same gap to the outside diameter

of the notch in the primary mass as demonstrated with the green dotted line in Fig. 85 – 42.

Fig. 85 - 42 Bearing Friction Ring

If the friction ring is covered by the secondary mass thus the inner diameter can not be seen

completely the ring has to be repositioned. Therefore lift the secondary mass slightly thus the ring can

be repositioned with a small screwdriver. The correct position is reached when the inner diameter of

the ring has approximately the same gap to the outside diameter of the notch in the primary mass as

demonstrated with the green dotted line in Fig. 85 – 42.

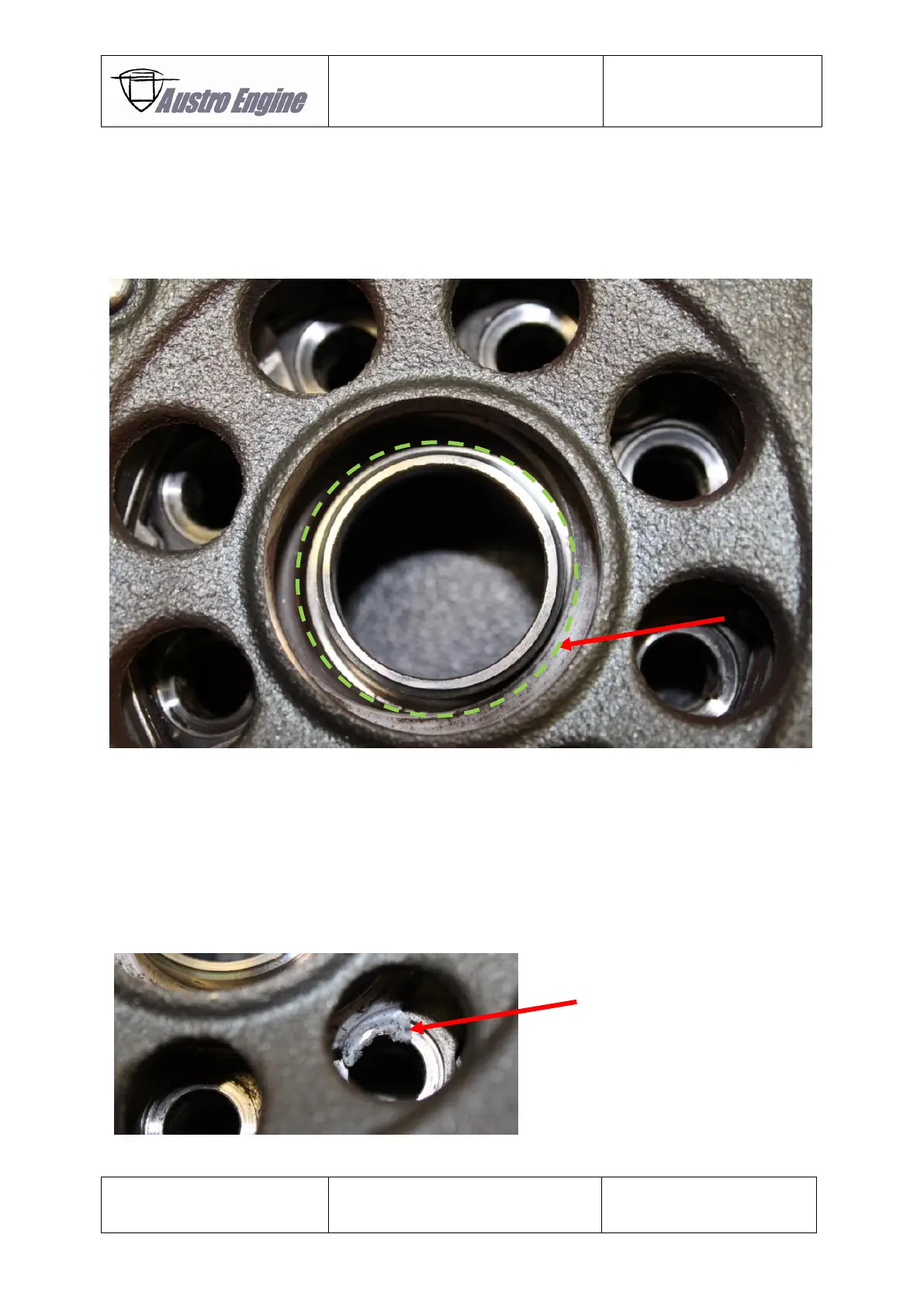

If the friction ring is not in the correct position the ring can be damaged when the Two-Mass-Flywheel

is mounted at the test rig for mechanical investigation. This damage is seen in the following figure.

Fig. 85 - 43

Loading...

Loading...