152

FUEL SYSTEM

FUEL COMPONENT SERVICING

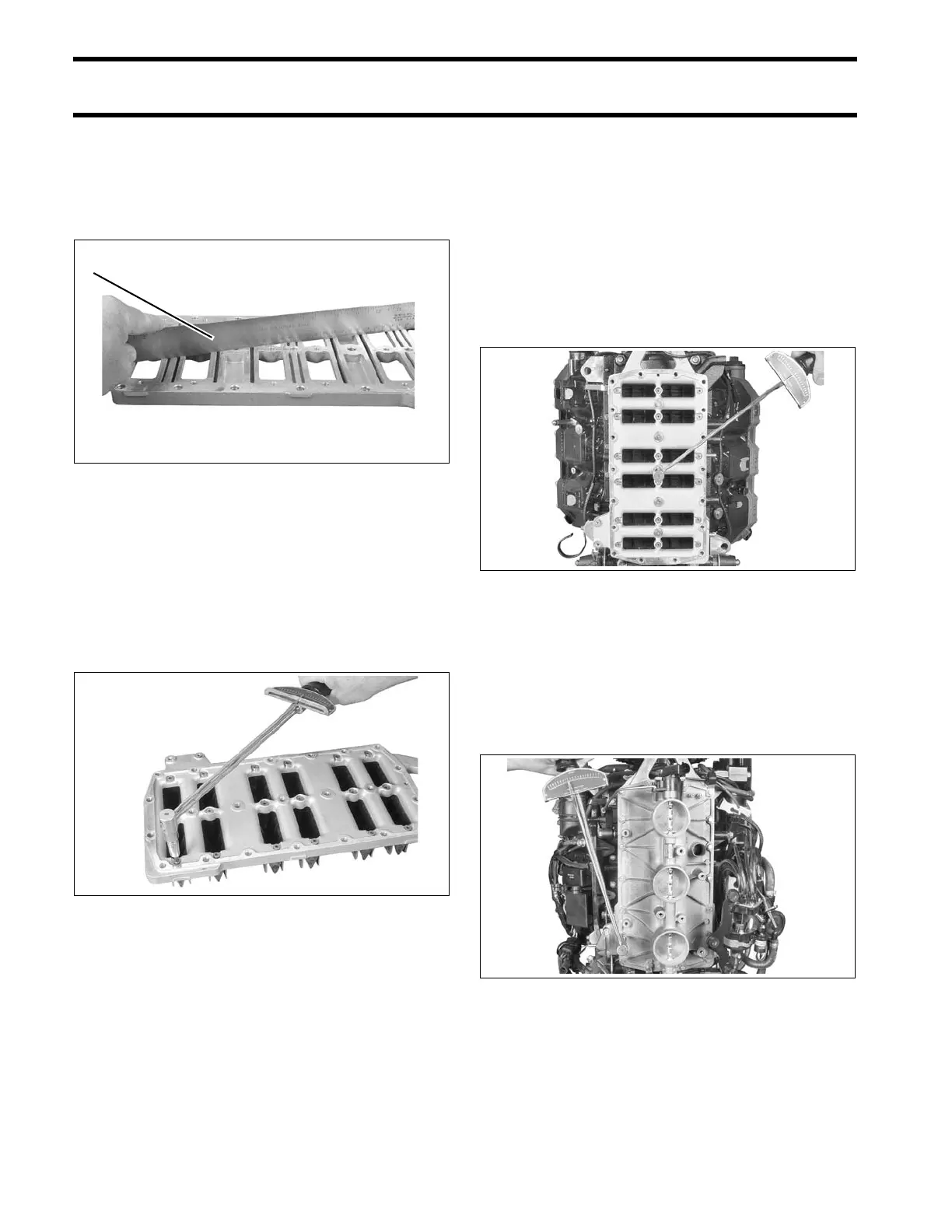

Inspect the int ake manifold . All gasket su rfaces

must be cleaned, smooth, and free of nicks. Use a

machinist’s st raight-edge an d a feeler gaug e to

check flatness in all directions. Surface mu st be

flat, ±0.004 in. (0.10 mm).

Assembly

Remove old adhesive from reed valve ret aining

screws.

Prime screw th reads with Locquic Primer and let

dry. Apply Nut Lock to threads. Position reed valve

on reed plate an d install screws. T ighten screws

to a torque of 30 to 42 in. lbs. (3.5 to 4.7 N·m).

Installation

Install ga sket on reed plate assembly . DO NOT

use sealer on the gasket.

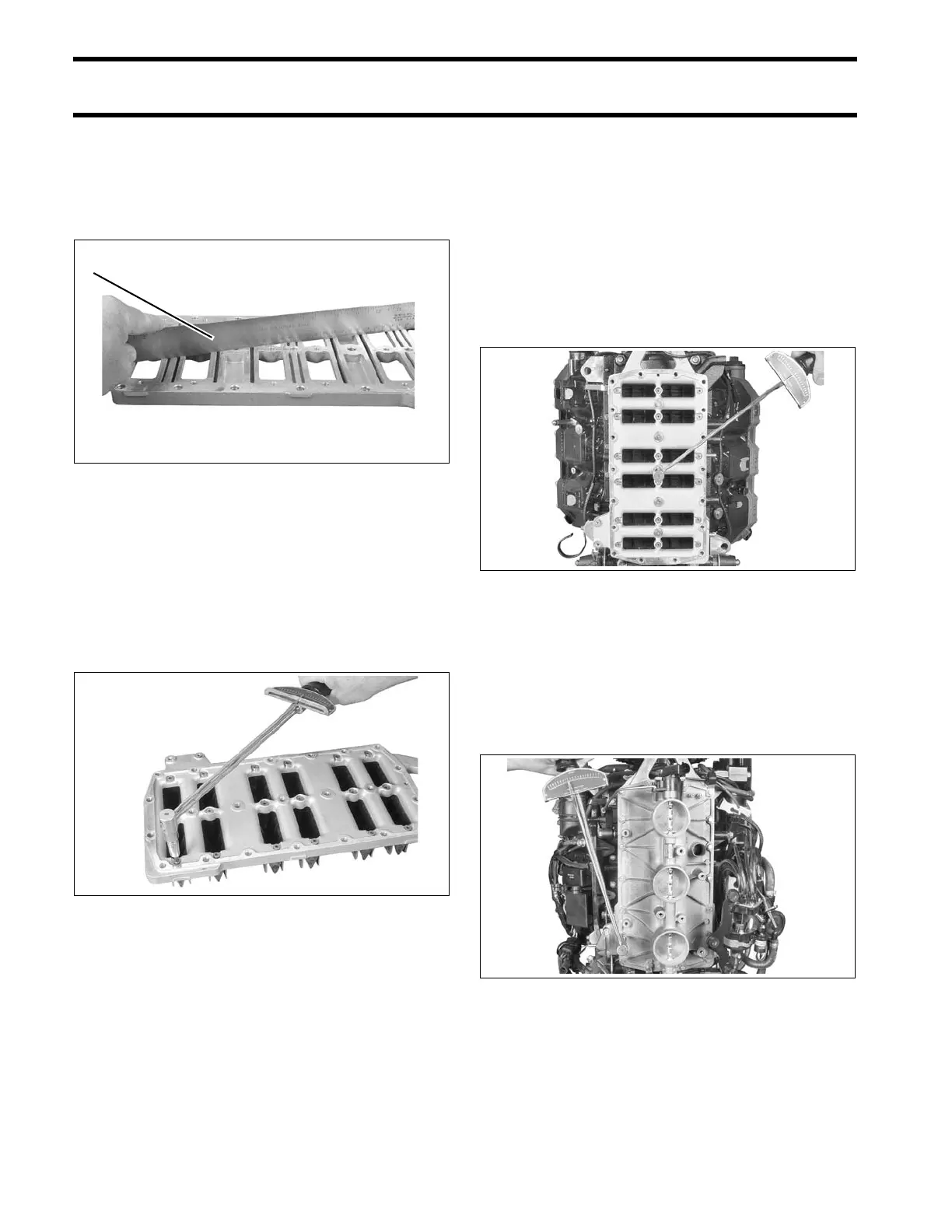

Place reed plate assembly on cylinder/crankcase.

Apply Nut Lock to screws. Install all screws.

Tighten the cente r screws first and exp and o ut-

ward. Tighten in st ages to a final to rque of 96 to

120 in. lbs. (11 to 13.5 N·m).

Place gasket on throttle body. Install throttle body,

with o il pump bracket on reed plate and inst all

screws.

Tighten the cente r screws first and exp and o ut-

ward. Final torque is 60 to 84 in. lbs. (7 to 9 .5

N·m).

Install crankshaft position sensor.

Install vapor separator vent hose and oil recircula-

tion hose. Secure with tie straps.

1. Straight-edge 004193

004194

004205

004257

Loading...

Loading...