A-12

Appendix A Scanner

®

2000 microEFM

Turbine Flowmeter Input 2

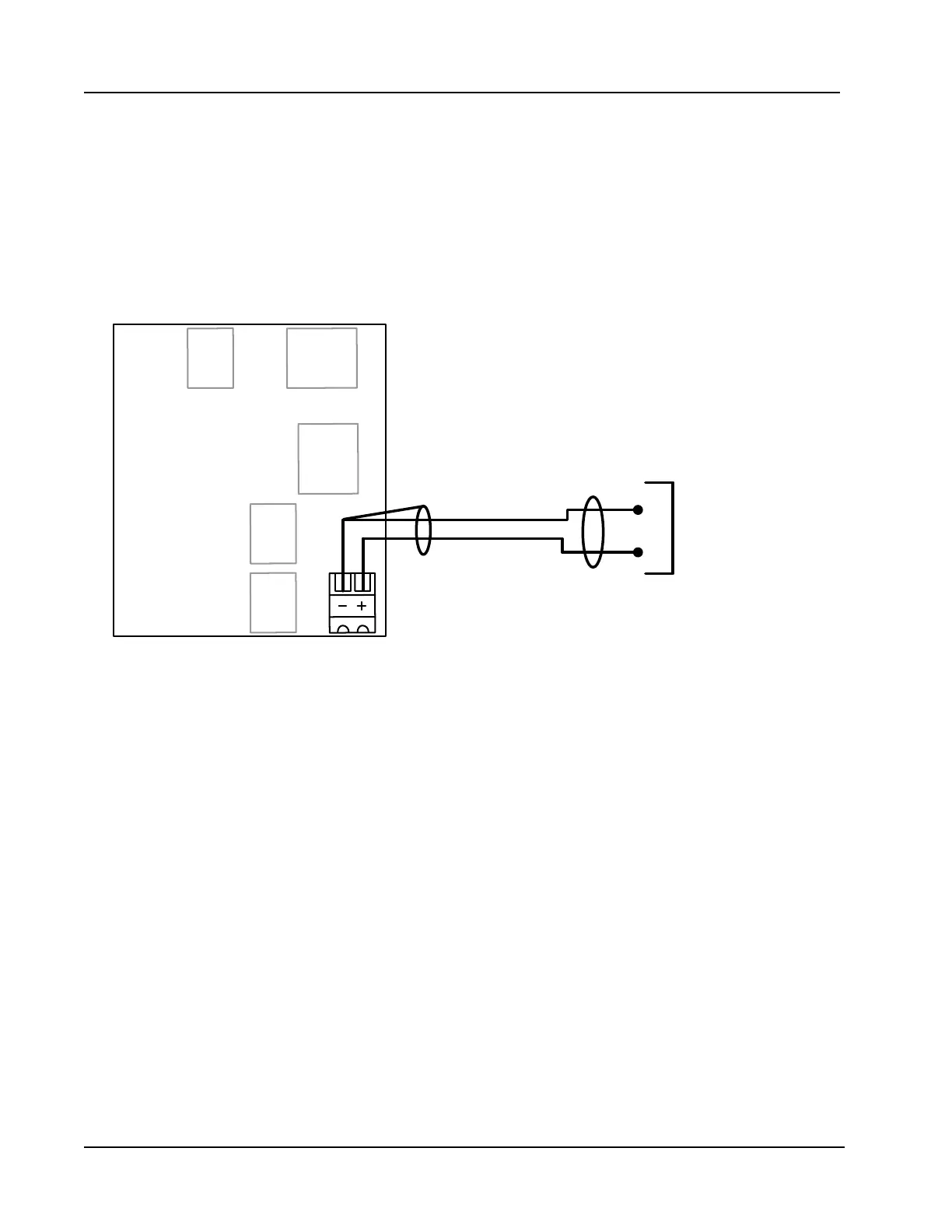

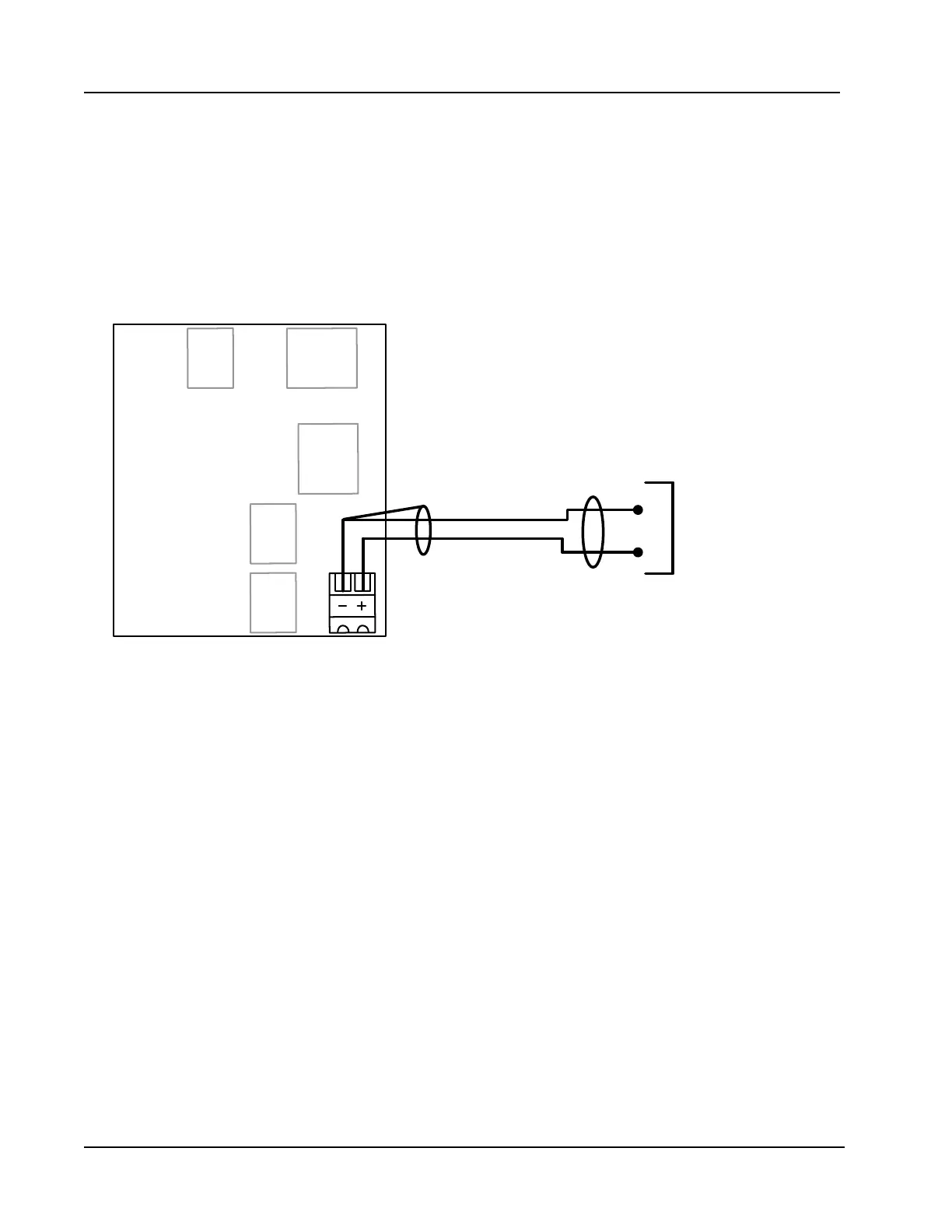

Turbine Input 2 (Figure A.17) accepts a turbine owmeter input signal generated by a magnetic pickup.

The Scanner 2000 can be congured to use this signal to calculate and display instantaneous ow rates and

accumulated totals. Turbine Input 2 is in addition to the turbine input on the main circuit board. When the

expansion board is installed, a differential pressure ow run and two turbine runs can be monitored and

logged simultaneously.

TURBINE

MAGNETIC PICKUP

B

A

2827

RED

BLACK

TB9

TB8 TB7

TB6

TB4

TB5

TURBINE INPUT (TB9)

Expansion

Board PN:

9A-30160014

Figure A.17—Turbine Input 2 wiring

Analog (4-20 mA) Output

The 4-20 mA output provides a linear current output that can be congured using ModWorX Pro software to

represent any parameter in the holding registers. This output requires a two-conductor cable to be connected

to an 8 to 30 VDC power supply (voltage required is dependent on loop resistance) and a current readout

device to be located in the remote location. See the ModWorX Pro Software User Manual for information on

conguring zero and full-scale values using ModWorX Pro software.

The graph below the wiring diagram in Figure A.18, page A-13 shows the minimum voltage required to power the

instrument for a given loop resistance. In addition, the mathematical relationship between loop voltage and

load resistance is given. For example, if a power supply voltage of 24 volts is available to power the current

loop, the maximum load resistance would be 800 ohms.

Loading...

Loading...