Chapter 9 Maintenance and Inspections | VP3000

608

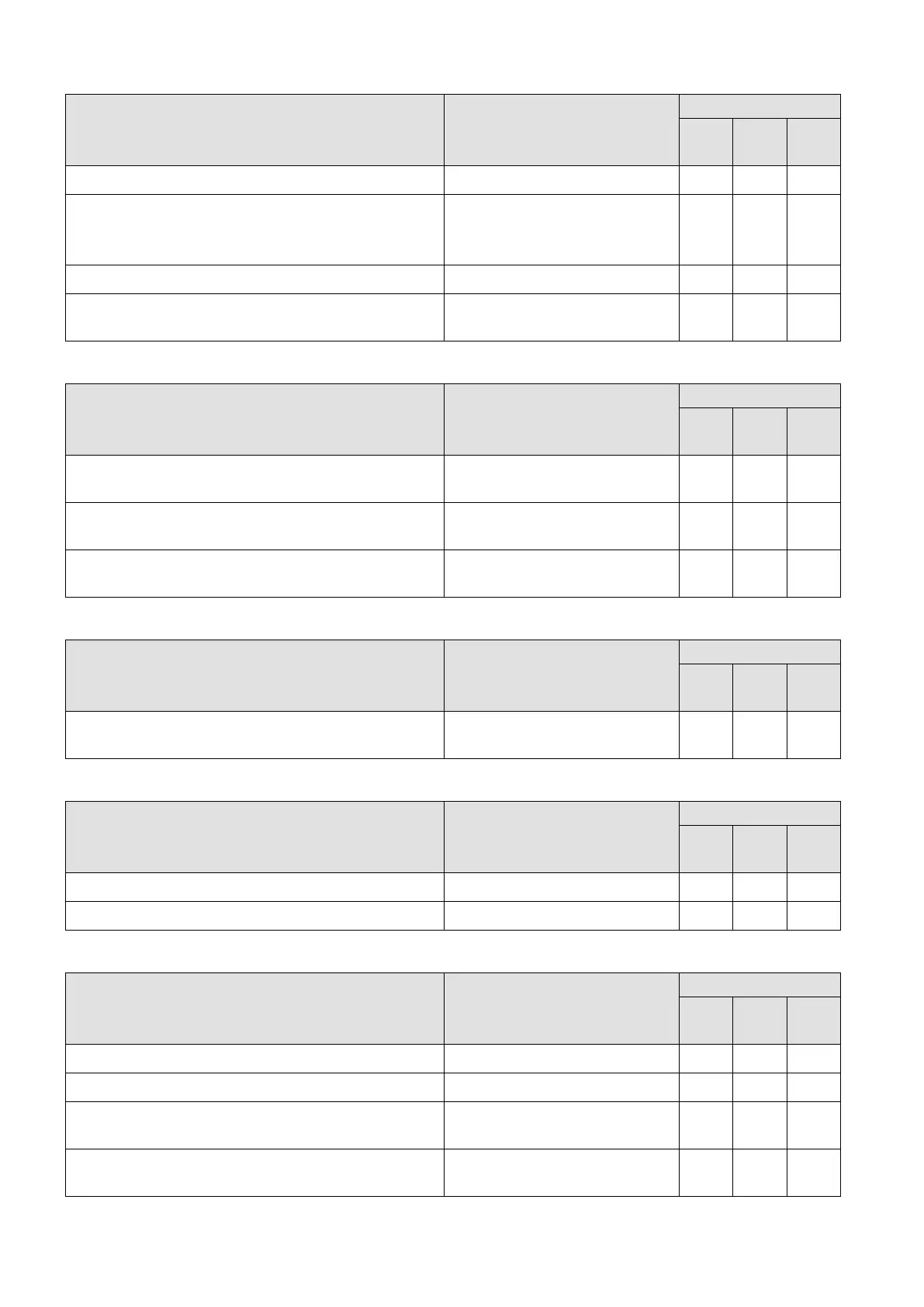

⚫ Main Circuit - Terminal and wiring

Check for any loose or missing screws

If there is any deformed, cracked, or damaged

machinery / insulation, or any color changed due

to overheating and aging.

Check for any dust or dirt

Check for wiring insulation damage or color

changed

⚫ Main Circuit - Filter Capacity

Check for any leakage of liquid, color changed,

cracking or deformation

Check if the safety valve is not removed or is

obviously expanded

Measure the static capacity when required

Measure with equipment with

standard specifications

⚫ Main Circuit - Transformer and Reactor

Check for any abnormal vibrations or peculiar

odors

Visual and auditory inspection

⚫ Main Circuit - Electromagnetic Contactor and Relay

Check for any vibration sounds

If the contact works correctly

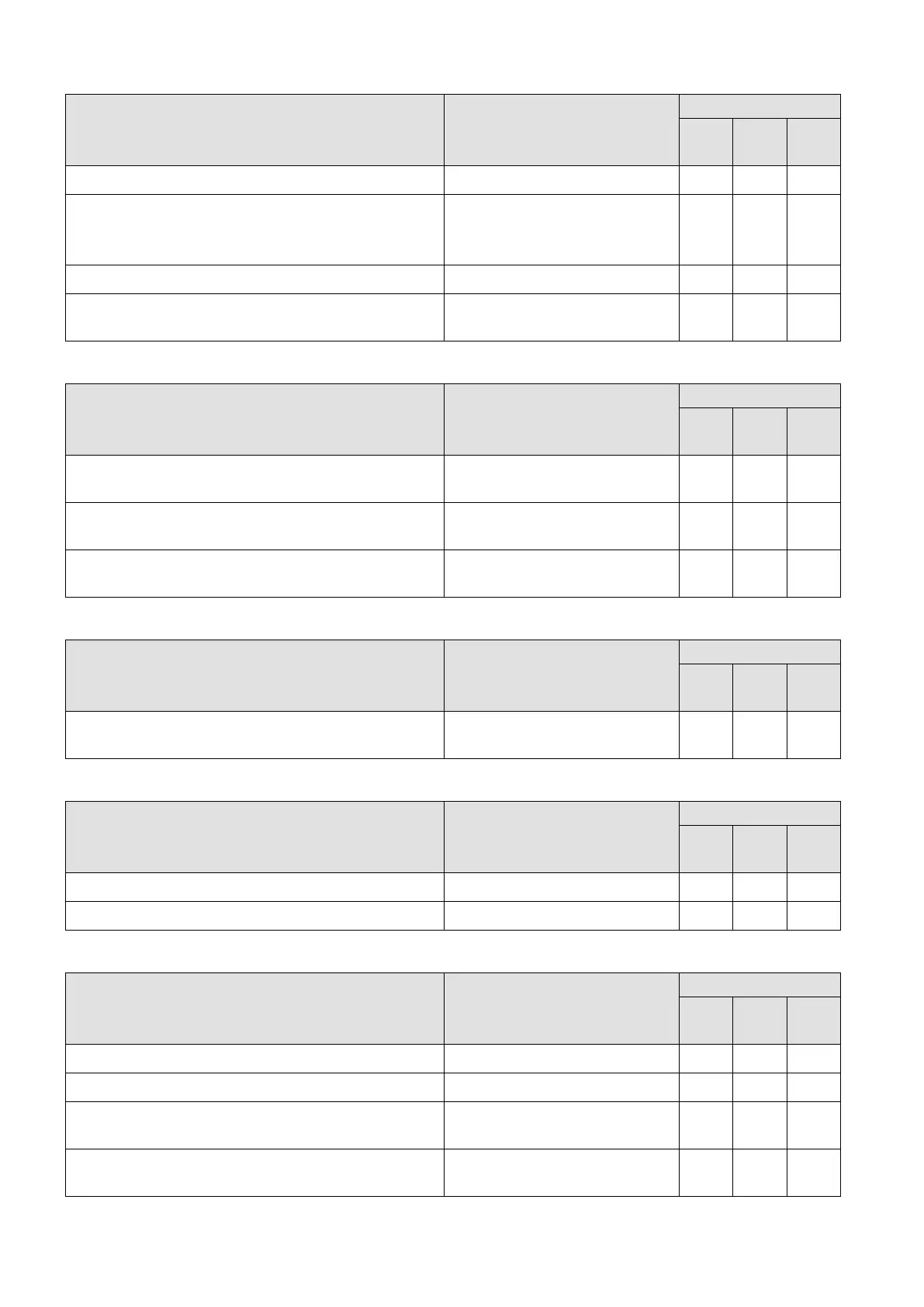

⚫ Control Circuit - PCB and Connector

Check for any loose screws and connectors

Check for any peculiar odors or color changed

Visual inspection and smell

Check for any cracking, damage, deformation or

corrosion

Check for any leakage of liquid or deformation in

the capacitors

Loading...

Loading...