Nose Unit Overview and Precautions

The Role of the Nose Unit

Attaching the nose unit and setting [AUTO Z CONTROL] to [ON] enables automatic detection of the Z origin as the

position where the tip of the nose unit touches the surface of the workpiece. This makes it possible to perform

engraving on a workpiece of uneven surface height at a uniform depth. It also eliminates the need to set the Z

origin each time you engrave more than one dierent workpiece.

Nose Unit Limitations

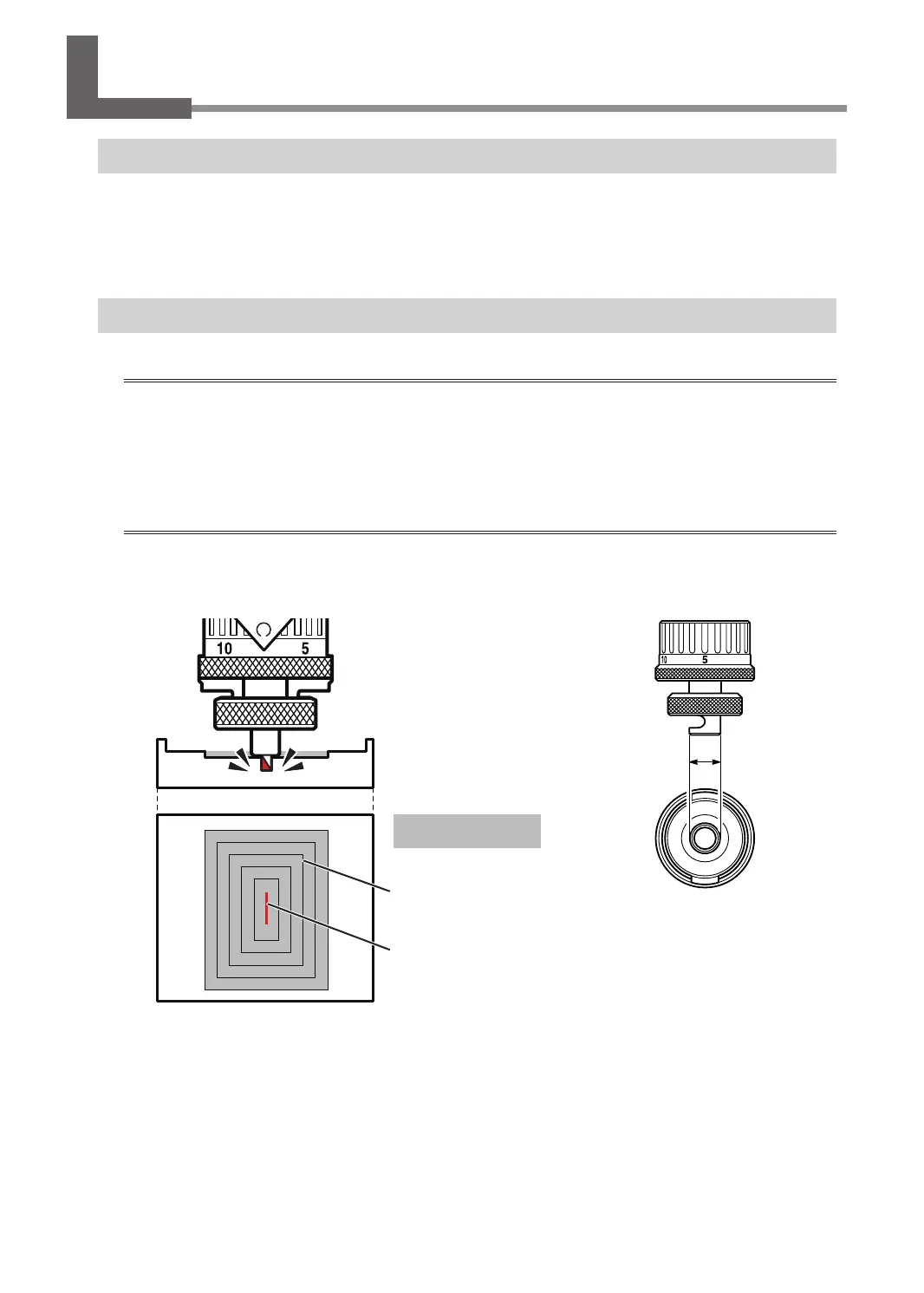

Trackable height displacement

When [AUTO Z CONTROL] is set to [ON], then as long as the tip of the nose unit is in contact with the surface of the

workpiece, the engraving depth can be kept uniform even if the height of the workpiece changes. However, there

is an upper limit to the amount of height displacement that can be tracked. Before you do the actual engraving,

carry out an engraving test to make sure the desired engraving can be accomplished.

• Trackable undulation height: Gentle undulations of about 1 mm (0.04 in.)

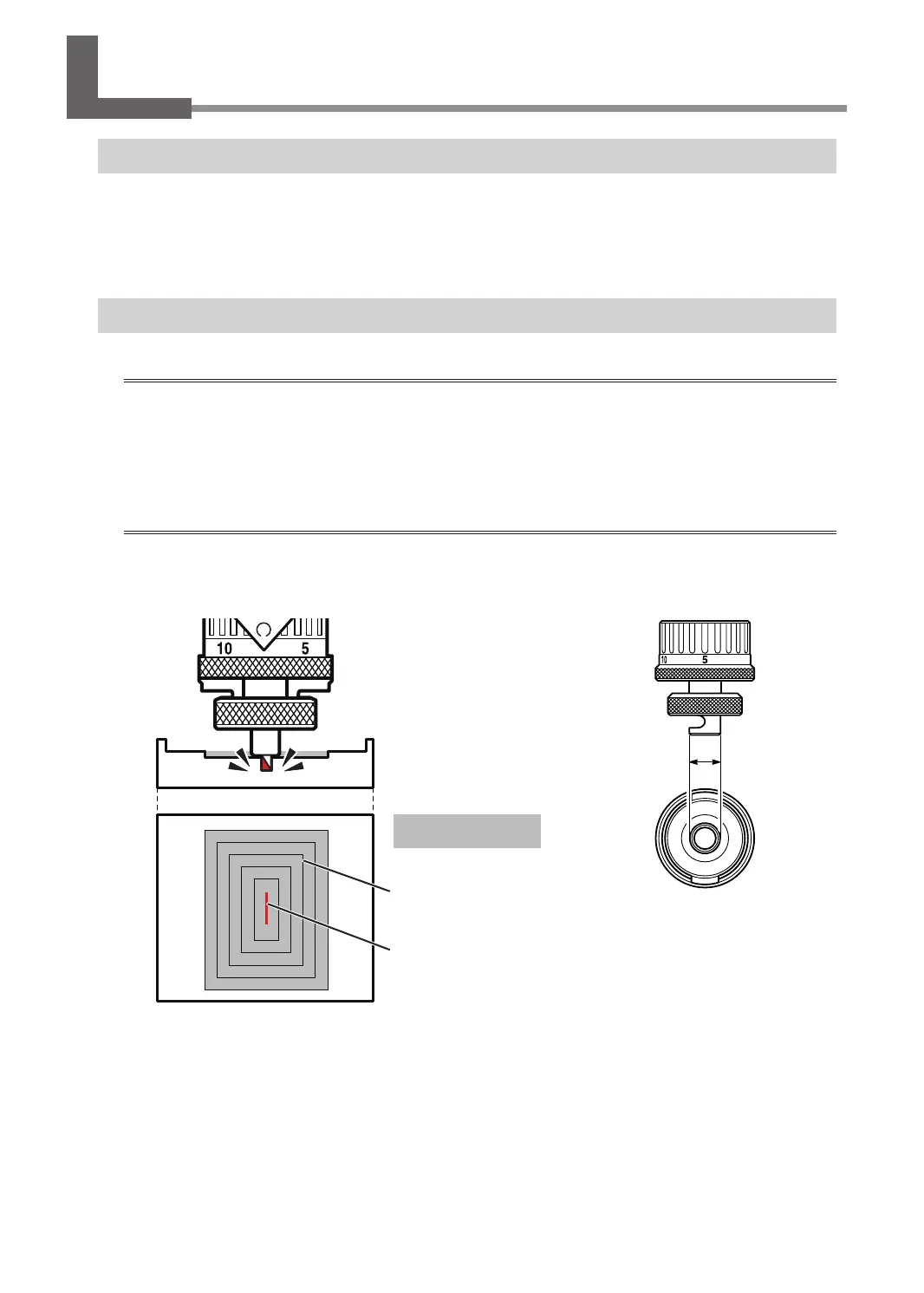

Fill range

The nose unit cannot be used with ll engraving over a wider range than the 8 mm (0.3 in.) diameter of the tip of

the nose unit. Using the nose unit may lead to engraving deeper than an already engraved surface with the nal

pitch.

8 mm (0.3 in.)

Tool path (path the tool takes)

Final pitch (nal path that the tool takes)

Area already worn o

83

Chapter 5 Various Engraving Methods

Loading...

Loading...