Considering Engraving Parameters

This machine lets you perform engraving using a wide variety of workpiece materials and tools. However, the

optimal engraving conditions that yield the desired engraving results for these combinations vary.

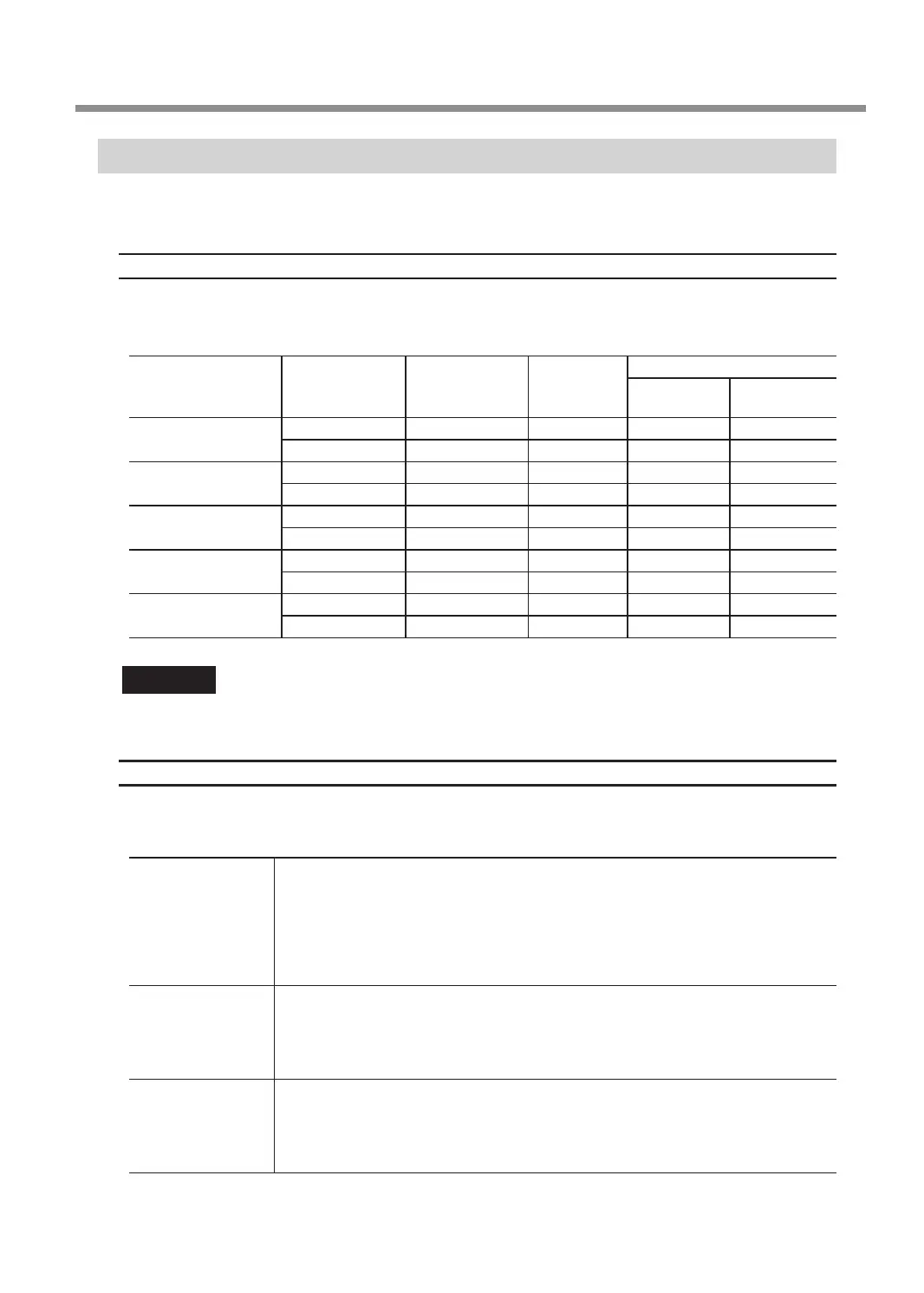

Typical Setting by Material

The table below shows suggested tools and engraving parameters suited to various types of workpieces. Refer to

these when selecting the engraving conditions. Before you perform the actual engraving, carry out an engraving

test and adjust each condition.

Workpiece material Tool type

Spindle

rotating speed

(RPM)

Cutting-in

amount

(mm)

Feeding speed

XY speed

(mm/sec.)

Z speed

(mm/sec.)

Acrylic

ZEC-A2025 15000 0.2 15 5

ZEC-A2320 15000 0.2 15 5

Aluminum

ZEC-A2025-BAL 15000 0.1 5 1

ZDC-A2000 No rotation - 10 1

Brass

ZEC-A2025-BAL 15000 0.1 5 1

ZDC-A2000 No rotation - 10 1

Chemical wood

ZEC-A2025 15000 0.45 8 7

ZEC-A2320 15000 0.45 8 4

Modeling wax

ZEC-A2025 15000 0.5 30 10

ZEC-A2320 15000 0.2 30 5

Important

Never use a ø4.36 mm (0.17 in.) tool at a spindle rotating speed higher than 15,000 rpm. Doing so may lead to

spindle unit damage due to vibrations.

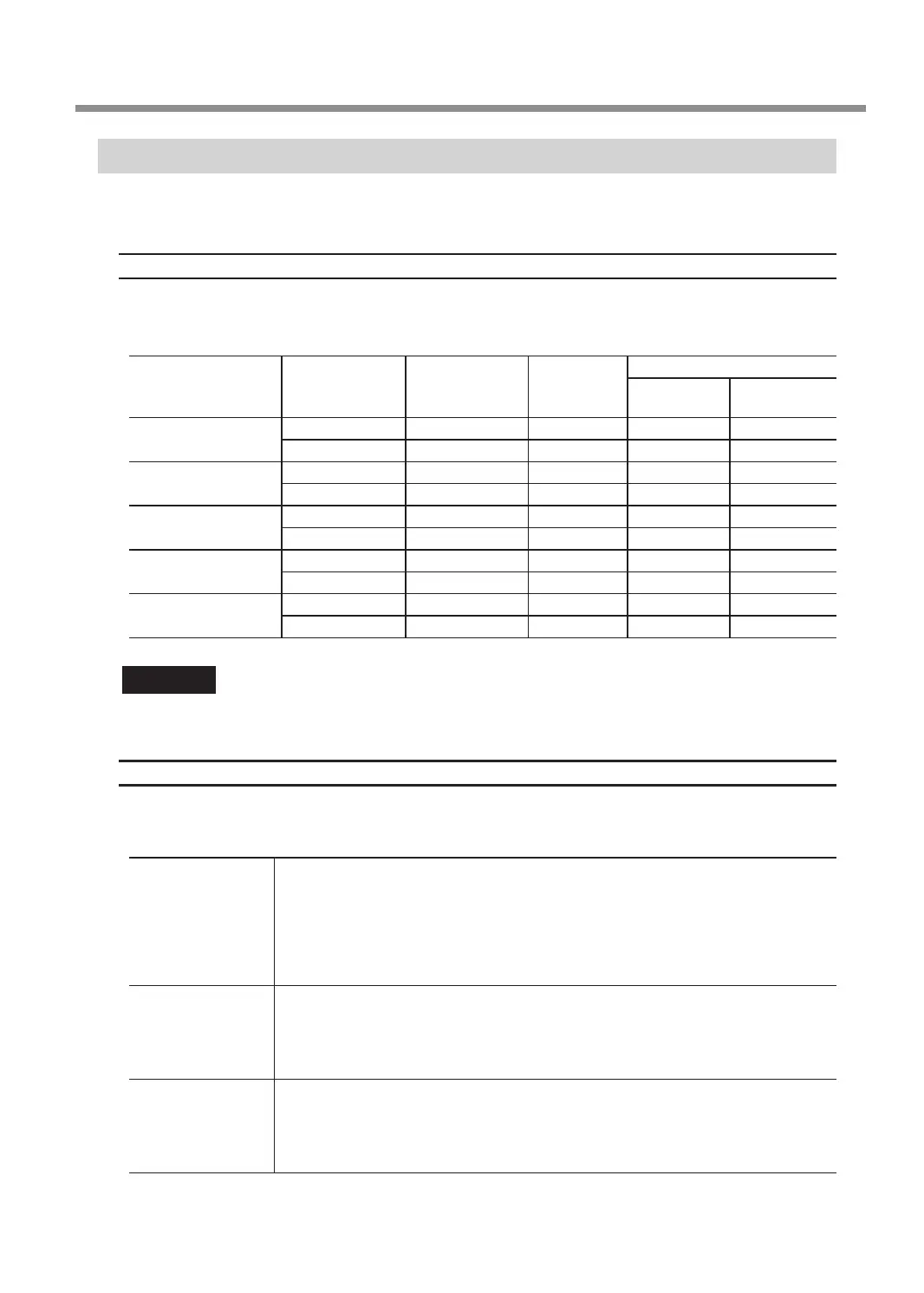

Tips for Fine-tuning

The optimal conditions are determined by the balance between factors such as the workpiece hardness, the

feeding speed, the spindle rotating speed, the cutting-in amount, and the capability of the tool. Refer to the

following tips and try ne-tuning the conditions.

Spindle rotating

speed

In general, faster rotation provides increased engraving capacity. However, a feeding

speed that is too slow with respect to the number of rotations may lead to melting of the

workpiece due to heat or to increased burring or roughness. Roughness may also occur

at some places because tool feeding stops momentarily at places where the direction

of engraving changes (that is, at corners). In this case, lower the number of rotations. It

may also be a good idea to use faster settings for narrower tools and slower settings for

wider tools.

Feeding speed

Faster speeds result in shorter engraving times, but the load also increases accordingly.

The load may overcome the strength with which the workpiece is secured in place,

resulting in crooked lines or a non-uniform engraving depth. Also, a feeding speed that

is too fast for the spindle rotating speed may result in roughness or a raised nap. In such

cases, lower the feeding speed.

Cutting-in amount

Deeper cutting-in amount results in a greater load, and roughness becomes more likely

to occur. When you make the cutting-in amount deeper, it is a good idea to raise the

spindle rotating speed and lower the feeding speed accordingly. Note, however, that

there is a limit to the maximum cutting-in amount. When deep engraving is required, it is

a good idea to perform double engraving and reduce the amount of engraving per pass.

Using Various Tools

87

Chapter 5 Various Engraving Methods

Loading...

Loading...