Products can be nished with higher quality by obtaining atness by cutting the workpiece table surface to a

uniform depth. This operation of obtaining atness is called "surface leveling." It is performed when rigorously

precise atness is required, such as for plate engraving, which is performed without using the nose unit.

Use the surface leveling data that is installed together with the software. It takes approximately 2 hours to

perform one surface leveling operation with the surface leveling data.

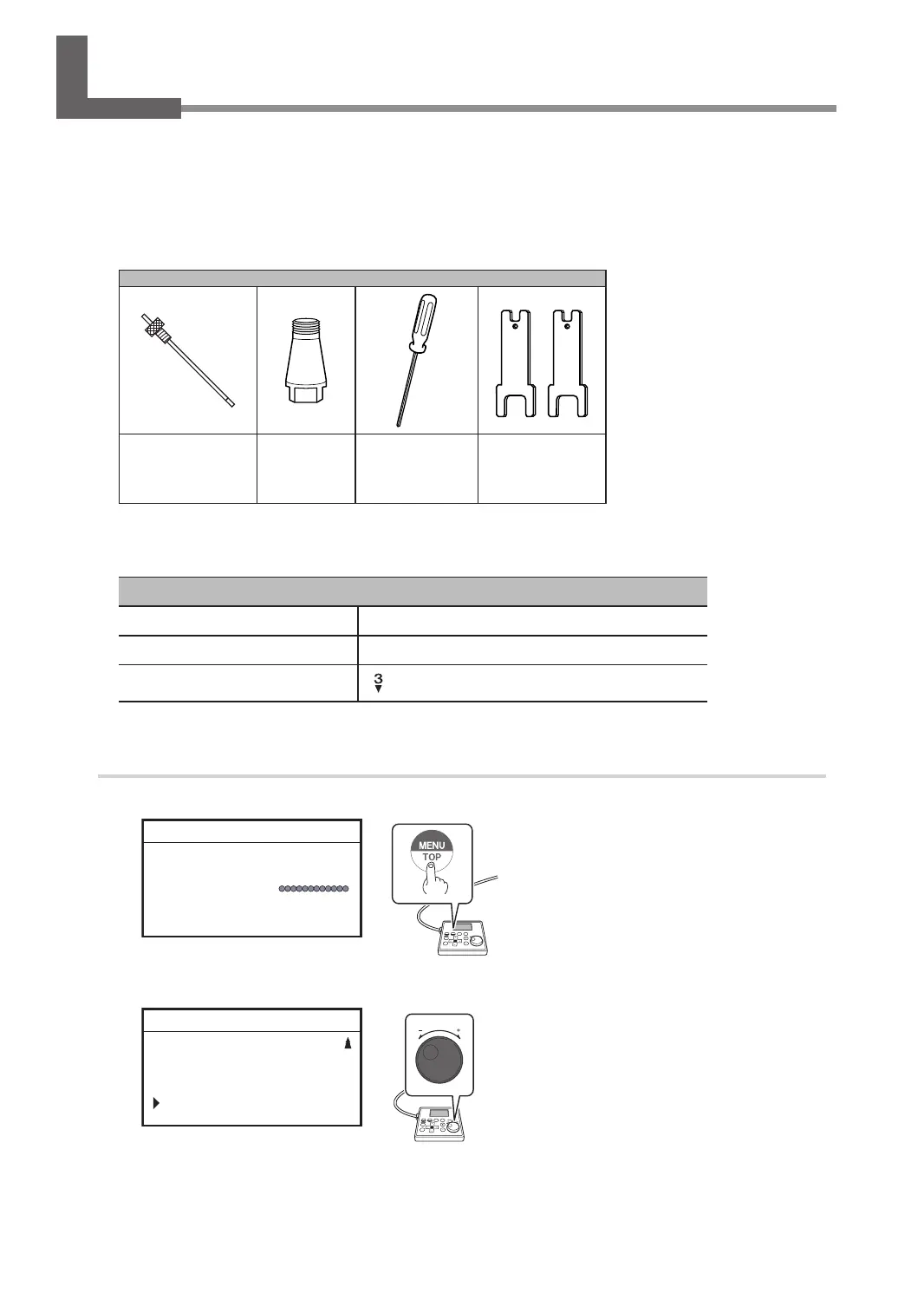

Items used in this procedure

Parallel cutter* Solid collet*

Hexagonal

screwdriver

Wrenches (2)

* Optional item (ZEC-A2320)

** There are two types of solid collets. Use a solid collet that ts the diameter of the cutter that will be used. Collet

for ø4.36 cutters is an optional item.

Settings for this machine

Automatic Z control OFF

Spindle rotation ON

Lock lever position

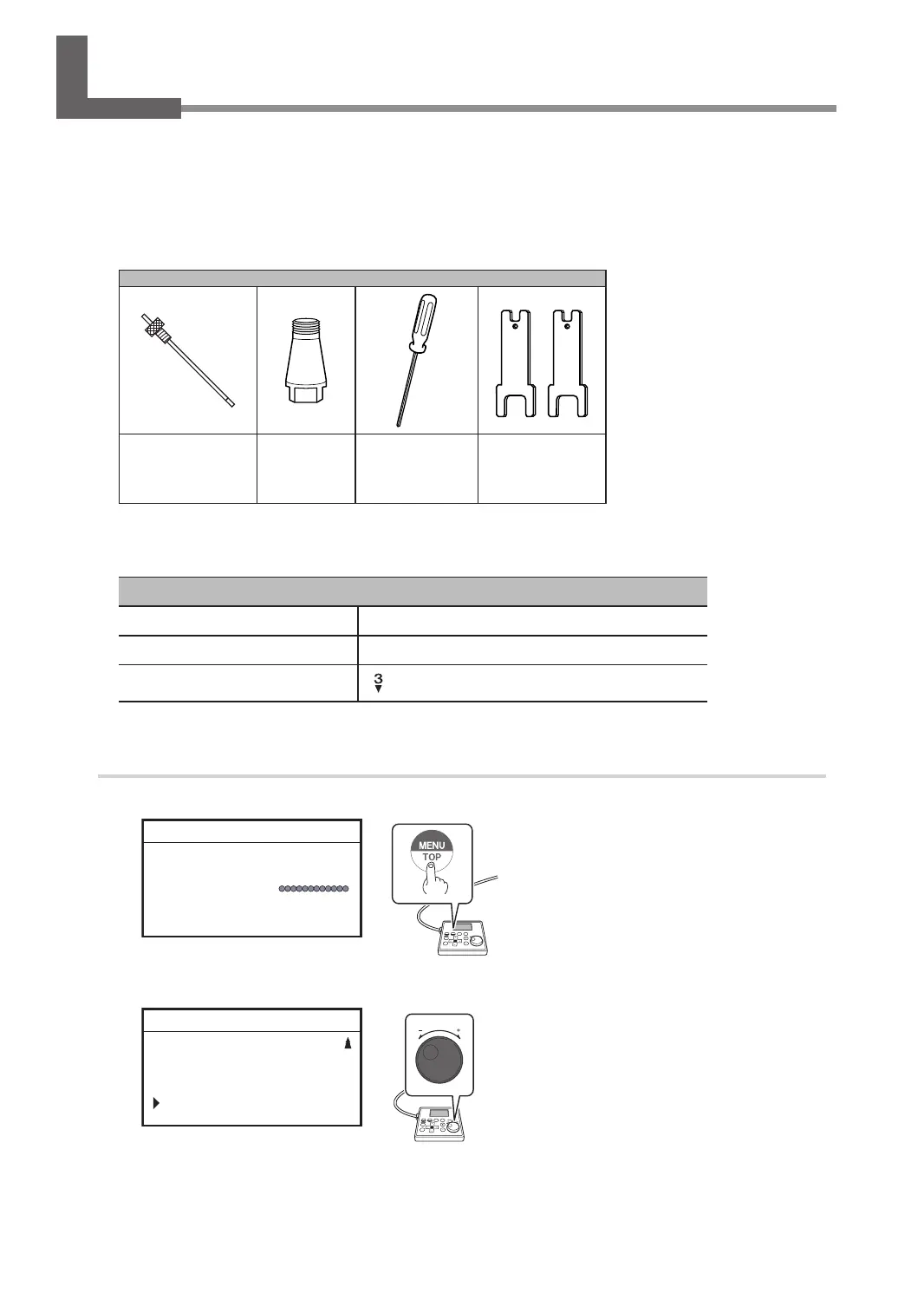

1.

Set the XY origin.

A

On the main screen, press [MENU/TOP].

X 15.00mm

Y 23.00mm

Z 0.00mm S 5000rpm

012345678901234567 READY

B

Turn the [Dial] and select [MACHINE ORIGN XY].

MOVE

CENTER

USER ORIGIN XY

MACHINE ORIGIN XY

012345678901234567 READY

Surface Leveling of the Workpiece Table

114

Chapter 5 Various Engraving Methods

Loading...

Loading...