Epson Artisan 810/835/837/710/725/730/Epson Stylus Photo PX810FW/TX810FW/PX820FWD/TX820FWD/PX830FWD/PX710W/TX710W/PX720WD/TX720WD/PX730WD/TX730WD

Revision G

TROUBLESHOOTING Troubleshooting without Error Message 78

Confidential

Paper ejection error

Carriage error

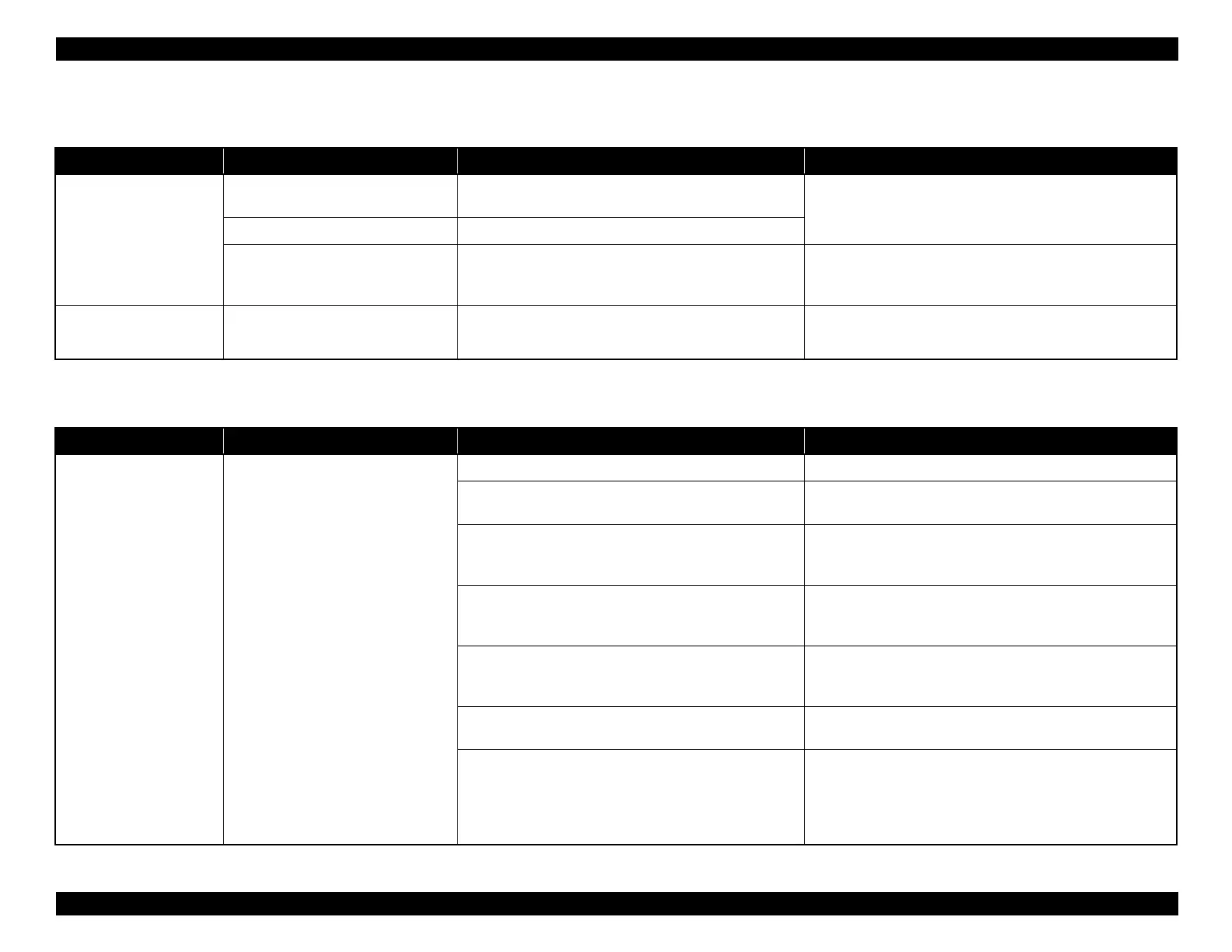

Table 3-18. Troubleshooting Paper Ejecting Problems

Problem Possible Cause Check point Remedy

Paper get jammed before

being ejected

Paper feed operation failure

Does the PF Roller rotate normally and is the rotational

force transmitted to the EJ Roller correctly?

Install the PF Motor properly and apply proper tension to the PF

Timing Belt.

(See "5.3.3 PF Timing Belt Tension Inspection" (p.235).)

EJ Roller operation failure Does the EJ Roller rotate normally?

EJ Frame operation failure Does the EJ Frame move normally?

Replace the Printer Mechanism with a new one.

(See "4.2.1 Parts transferred from the old printer when replacing

the Printer Mechanism" (p.108).)

The CDR Tray does not

come out.

CDR Tray operation failure

Are the dowels of the arms of the CDR Tray Assy correctly

attached with the grooves of the CDR Guide Base Assy/

Lower Paper Guide Assy?

Install the CDR Tray Assy correctly.

(See "4.2.5.9 CDR Tray Assy" (p.153).)

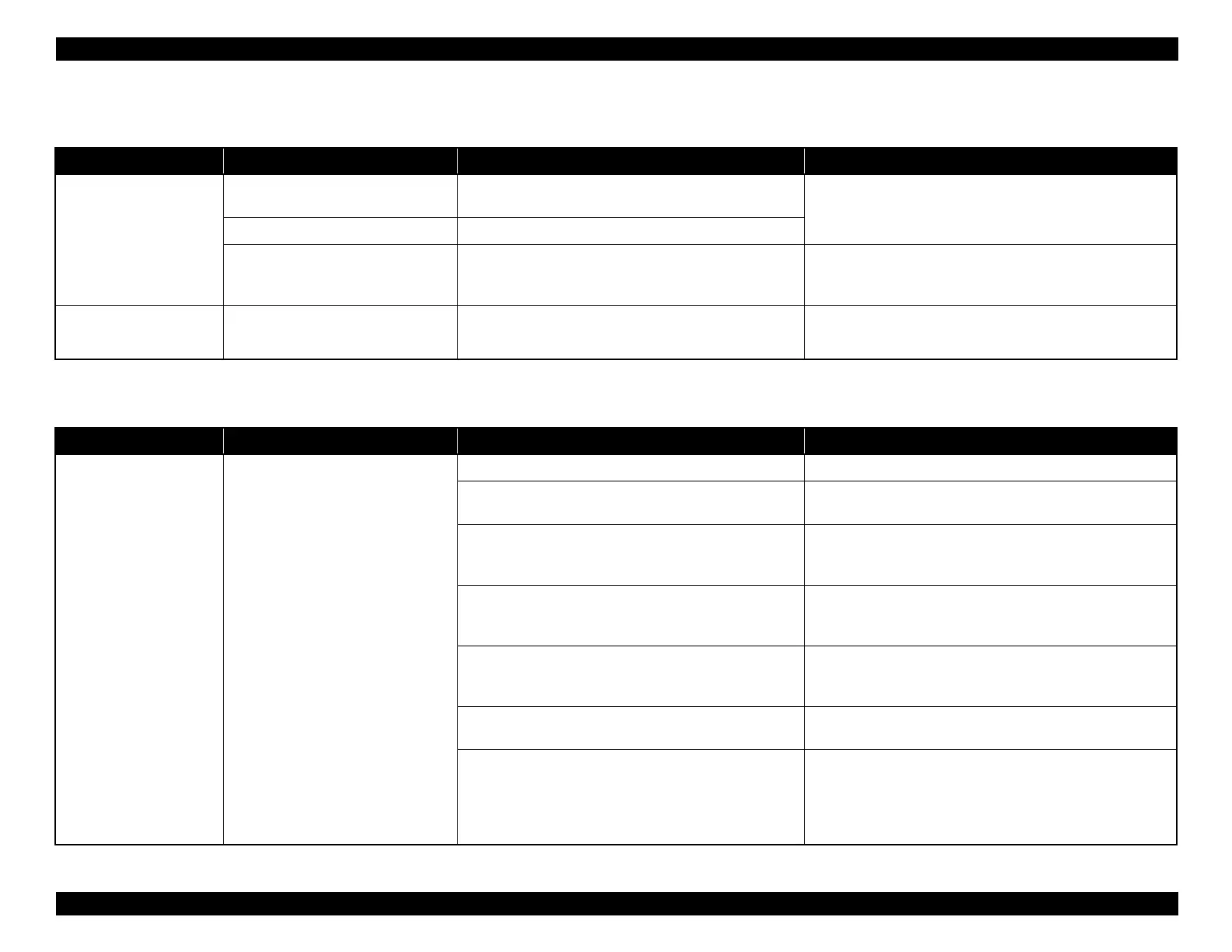

Table 3-19. Troubleshooting Carriage Movement Problems

Problem Possible Cause Check point Remedy

The movements of Carriage

Unit during printing is

abnormal

Something is obstructing the Carriage

movements.

Is there any obstructions on the Carriage path? Remove the obstructions.

Does the Carriage Unit move smoothly when it is manually

moved?

Clean the Carriage Shaft/CR Guide Plate and lubricate it as

specified. (See "6.1.3 Lubrication" (p.243).)

Does the Head FFC have an adequate slack and not

interrupting the Carriage movement? Check the FFC status

by manually moving the Carriage Unit from side to side.

Route the Head FFC correctly on the Main Frame.

(See "4.4 Routing FFC/cables" (p.196).)

Is the routing of the Ink Supply Tube Assy correct? Check

it and smoothness by manually moving the Carriage Unit

from side to side to both ends.

Route the Ink Supply Tube Assy.

(See "4.2.5.6 Ink Supply IC Holder Assy" (p.144).)

Is the CR Guide Plate correctly installed?

Replace the Printer Mechanism with a new one.

(See "4.2.1 Parts transferred from the old printer when replacing

the Printer Mechanism" (p.108).)

Is the PG adjustment appropriate?

Carry out the PG adjustment again.

(See "5.3.1 PG Adjustment/PG Inspection" (p.229).)

Is the tension of the CR Timing Belt appropriate?

Carry out the CR belt tension inspection. If it is still not

appropriate, replace the Printer Mechanism with a new one. (See

"5.3.2 CR Timing Belt Tension Inspection" (p.234), "4.2.1 Parts

transferred from the old printer when replacing the Printer

Mechanism" (p.108).)

Loading...

Loading...