Epson Artisan 810/835/837/710/725/730/Epson Stylus Photo PX810FW/TX810FW/PX820FWD/TX820FWD/PX830FWD/PX710W/TX710W/PX720WD/TX720WD/PX730WD/TX730WD

Revision G

ADJUSTMENT Adjustment without Using Adjustment Program 229

Confidential

5.3

Adjustment without Using Adjustment Program

This section explains the adjustment procedure without using the adjustment program.

5.3.1 PG Adjustment/PG Inspection

5.3.1.1 PG Adjustment

Described below is the platen gap (PG) adjustment.

Purpose:

Adjust the distance between the head surface and the Paper Guide Front Assy

(platen) properly and adjust the parallelism on the 0-digit side and on the 80-digit

side to ensure reliable print quality.

This adjustment is carried out when the position of the notch on the Parallelism

Adjustment Busings have changed, or when PG is not within the standard values

after PG checking.

Tools

Parallelism adjustment jigs (two types; the one for 0th column side and the

one for 80th column side)

Fixtures for precision control

Thickness gauge: 1.1 mm (x2)

1.3 mm (x2)

Phillips screwdriver

Hex wrench

Standard value

Specified PG value: 1.2 ± 0.1 mm

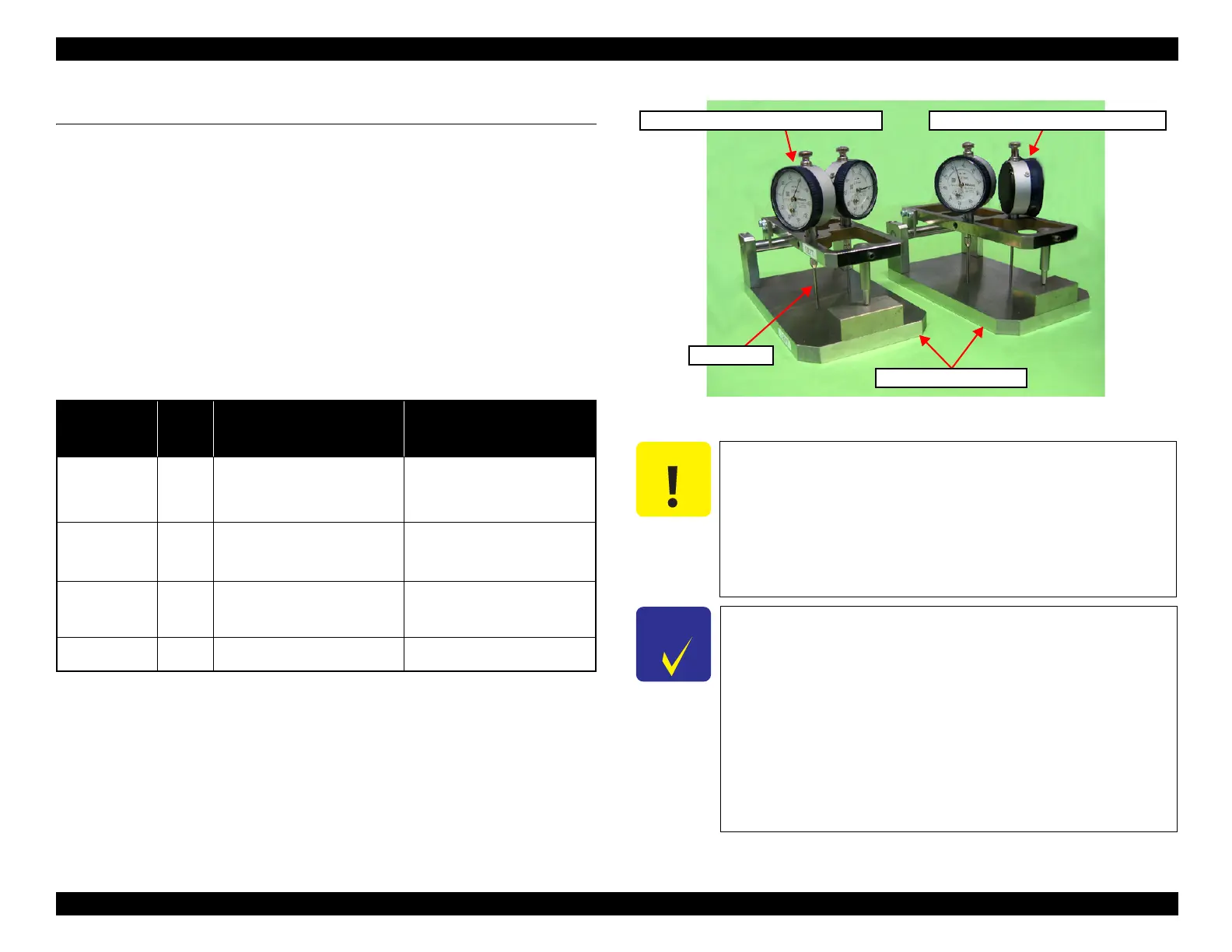

Figure 5-31. Parallelism adjustment jig/Fixtures for precision control

Table 5-7. PG Positions

Position

PG Size

(mm)

Application for Printing

(selected from PG flag list for

normal/head rubbing))

Sequence Application

PG-

<APG Home>

1.2 EPSON special paper

Applied while capping, wiping

operations, during standby after

power-on, performing AID

adjustment.

PG typ.

<Mechanical

default>

1.7

Plain paper

Select when PG- is too narrow

Applied while capping

PG+ 2.35

Envelopes

Select when PG typ. is too

narrow

Applied while capping

PG++ 2.95 CD/DVD

Applied while capping

Applied while EJ release operation

Handle the jigs with care because the bit on the shaft of dial

gauge of parallelism adjustment jigs is very fragile and gets

broken easily.

The thickness gauges to be used must be free from dust and dirt

and from deformation. Be sure to clean it before use.

Take care not to soil or scratch the Printhead.

Move the carriage right and left by pulling the belt, not by

holding down (or pressing) the carriage.

Carry out this adjustment with installing the Printhead, the Ink

Supply Tube Assy and the Cartridge Box Unit. (Install the CR

Scale after this adjustment) See

"4.2.5 Disassembling the

Printer Mechanism (p133) ".

Artisan 810/835/837/710/725/730/PX810FW/TX810FW/

PX820FWD/TX820FWD/PX830FWD/PX710W/TX710W/

PX720WD/TX720WD/PX730WD/TX730WD have four PG pre-

settings using the APG mechanism. Use the minimum PG

setting (PG

–: 1.2 mm) to carry out this adjustment.

See Figure. 5-36.

Carry out “PG Inspection (p.233)” only, if the position of the

notch on the Parallelism Adjustment Busings have not changed.

Parallelism adjustment jig (for 80th column side) Parallelism adjustment jig (for 0th column side)

Fixtures for precision control

Bit on the shaft

Loading...

Loading...