132 Powermax125 Service Manual 808070

8 – Troubleshooting and System Tests

Fault code format – 0-nn-n

These fault codes identify operational faults. On the operator screen, the last digit is omitted. Display the service screen

for more information on faults 11, 19, 30, 40, 60, and 99.

Fault codes beginning with zero (0-nn-n) are not recorded in the fault log.

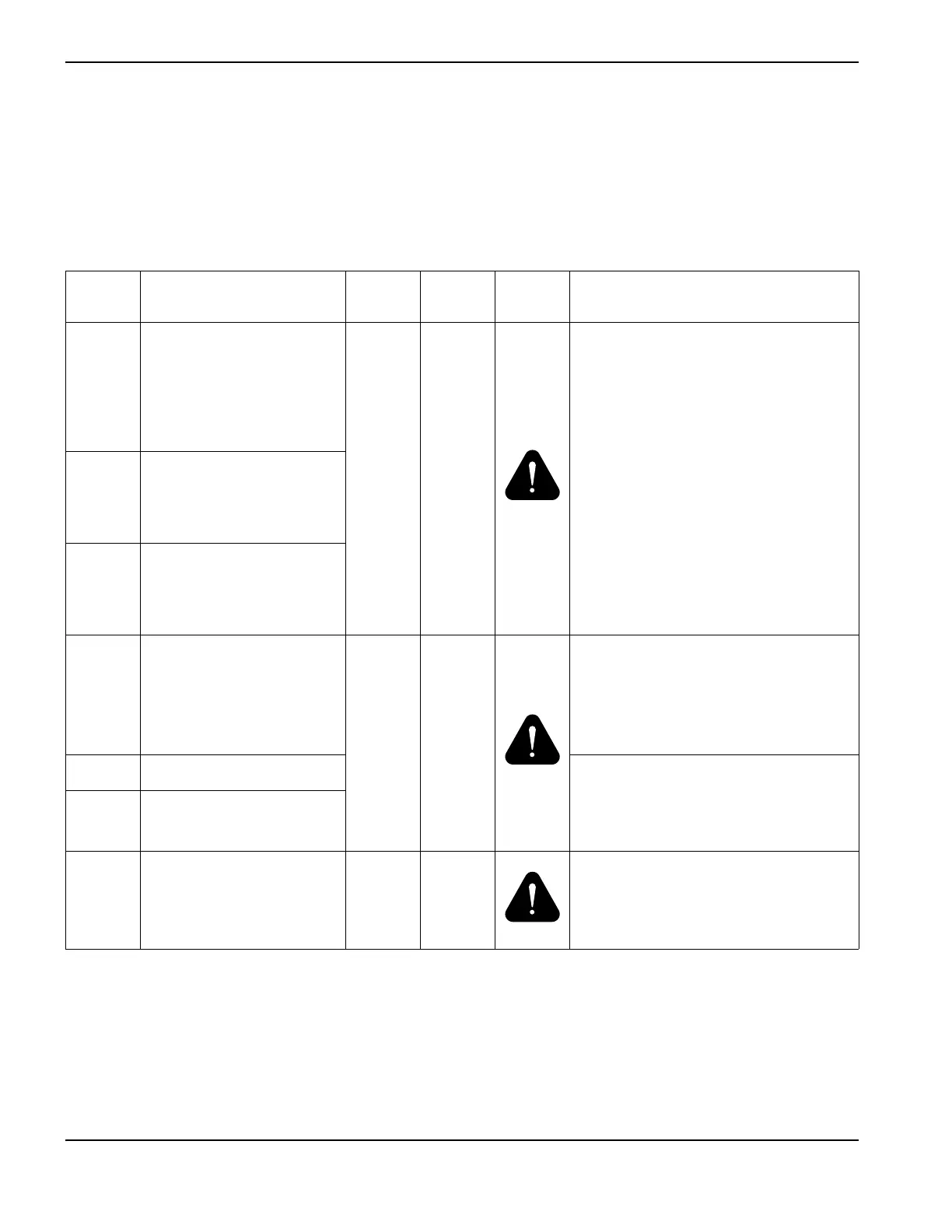

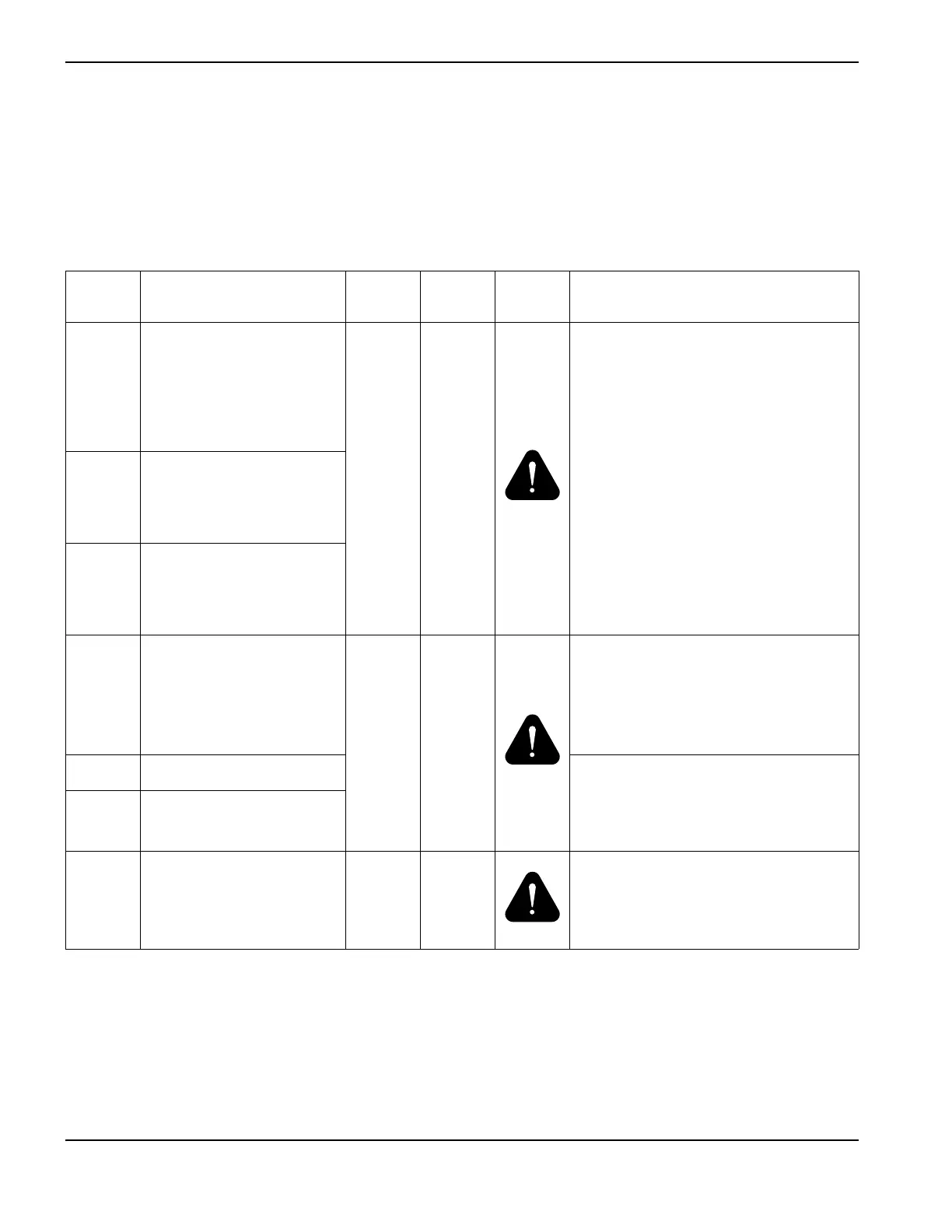

0-nn-n

Fault

code

Description

Power

LED

Fault

LED

Fault

icon

Solutions

0-11-0 Remote controller cut mode

invalid. Valid remote cut

modes for Powermax125:

1–Normal; 2–CPA

(continuous pilot arc);

3 – gouge; 5 – lock.

On Off

There is a problem with the remote

controller or the software interface to the

system. The system cannot interpret the

cut mode, cut current, or pressure

information coming from the controller.

• Fix the controller.

• Check the interface cable.

0-11-1 Remote controller current

invalid. Valid remote current

settings for Powermax125

are: 30 – 125 A.

0-11-2 Remote controller pressure

invalid. Valid remote pressure

setting for Powermax125

depends on the torch.

0-12-1 Output gas pressure low

On Off

• Adjust the gas inlet pressure as

needed.

• Check for kinked or blocked air lines.

•Perform Test 10 – Pressure sensor on

page 163.

0-12-2 Output gas pressure high • The gas subsystem is not working

properly. Check the valve.

•Perform Test 10 – Pressure sensor on

page 163.

0-12-3 Output gas pressure

unstable

0-13-0 AC input unstable (line

resonance): Alert

Blinks

(3 Hz)

Off

• Perform a cold restart.

• If the fault does not clear, correct the

power source. Change the character,

generally the impedance, of the line.

Loading...

Loading...