102 Powermax125 Service Manual 808070

7 – Mechanized Cutting

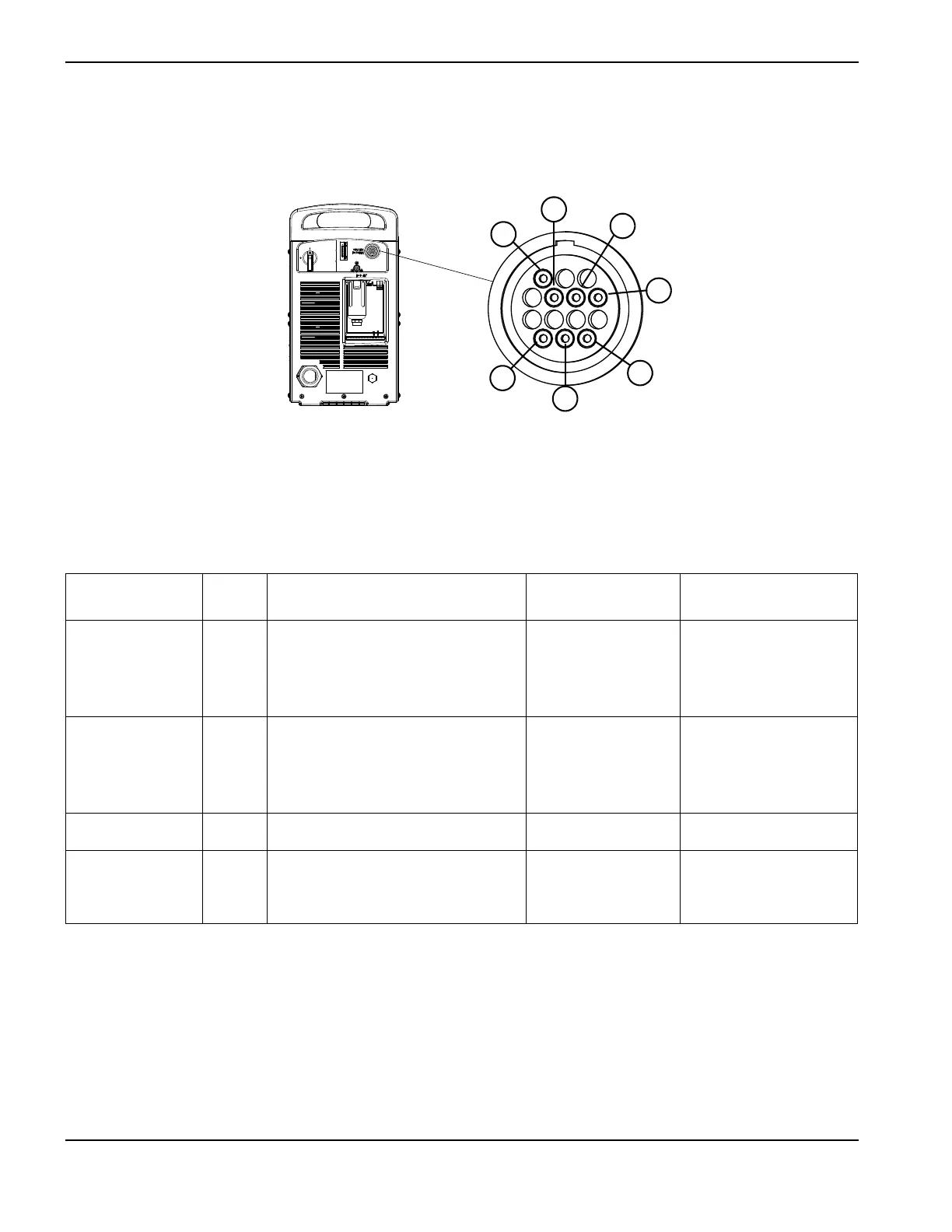

Machine interface pinout

Figure 2 – Connector sockets

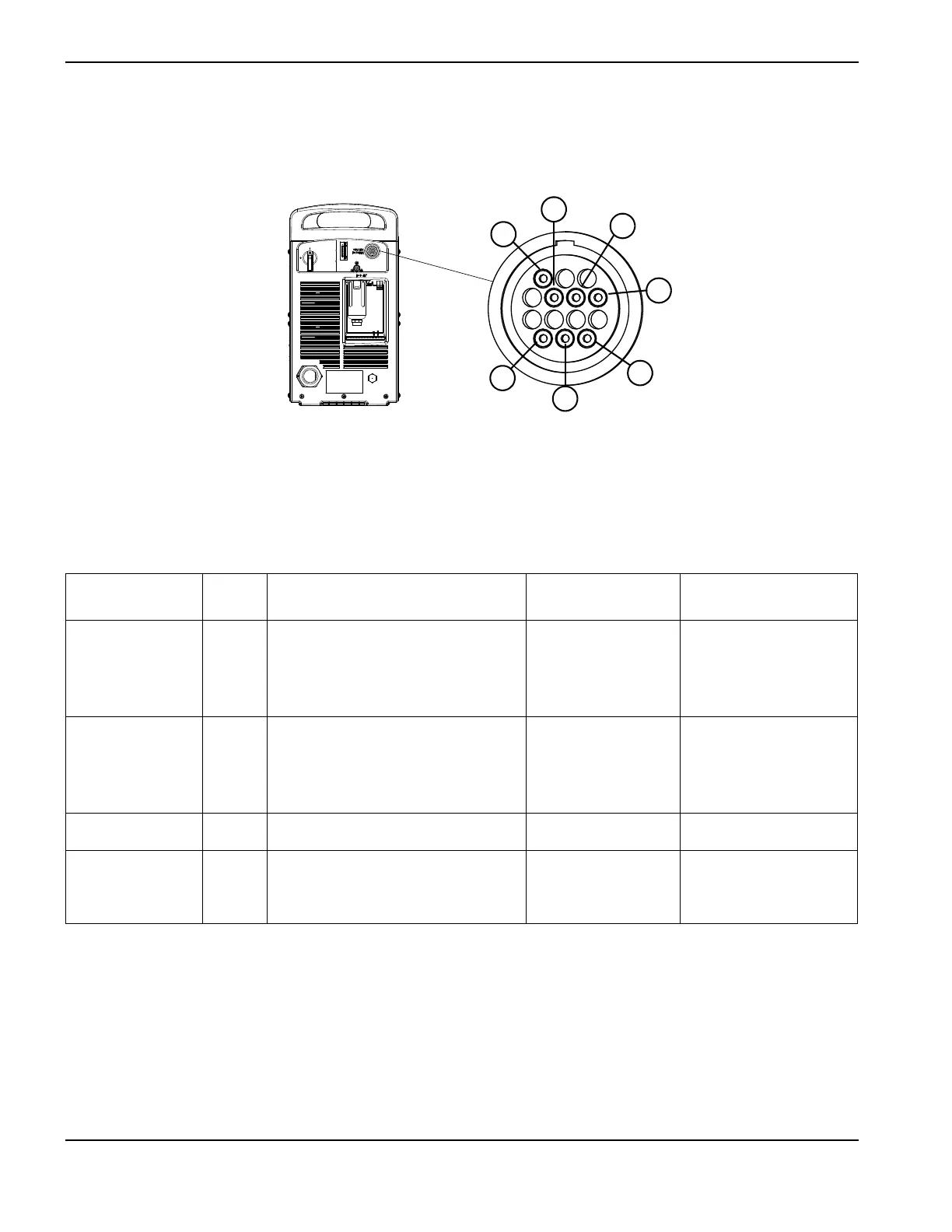

Refer to Table 11 when connecting the power supply to a torch height controller or CNC controller with a machine

interface cable.

Table 11 – Machine interface cable signals

Signal Type Notes Connector sockets External cable wires

Start (start

plasma)

Input Normally open.

18 VDC open circuit voltage at

START terminals. Requires dry

contact closure to activate.

3, 4 Green, black

Transfer (start

machine motion)

Output Normally open. Dry contact closure

when the arc transfers.

120 VAC/1 A maximum at the

machine interface relay.

12, 14 Red, black

Ground Ground 13

Voltage divider Output Divided arc signal of 20:1, 21.1:1,

30:1, 40:1, 50:1 (provides a

maximum of 16 V).

5(-), 6(+) Black (-), white (+)

Loading...

Loading...