146 Powermax125 Service Manual 808070

8 – Troubleshooting and System Tests

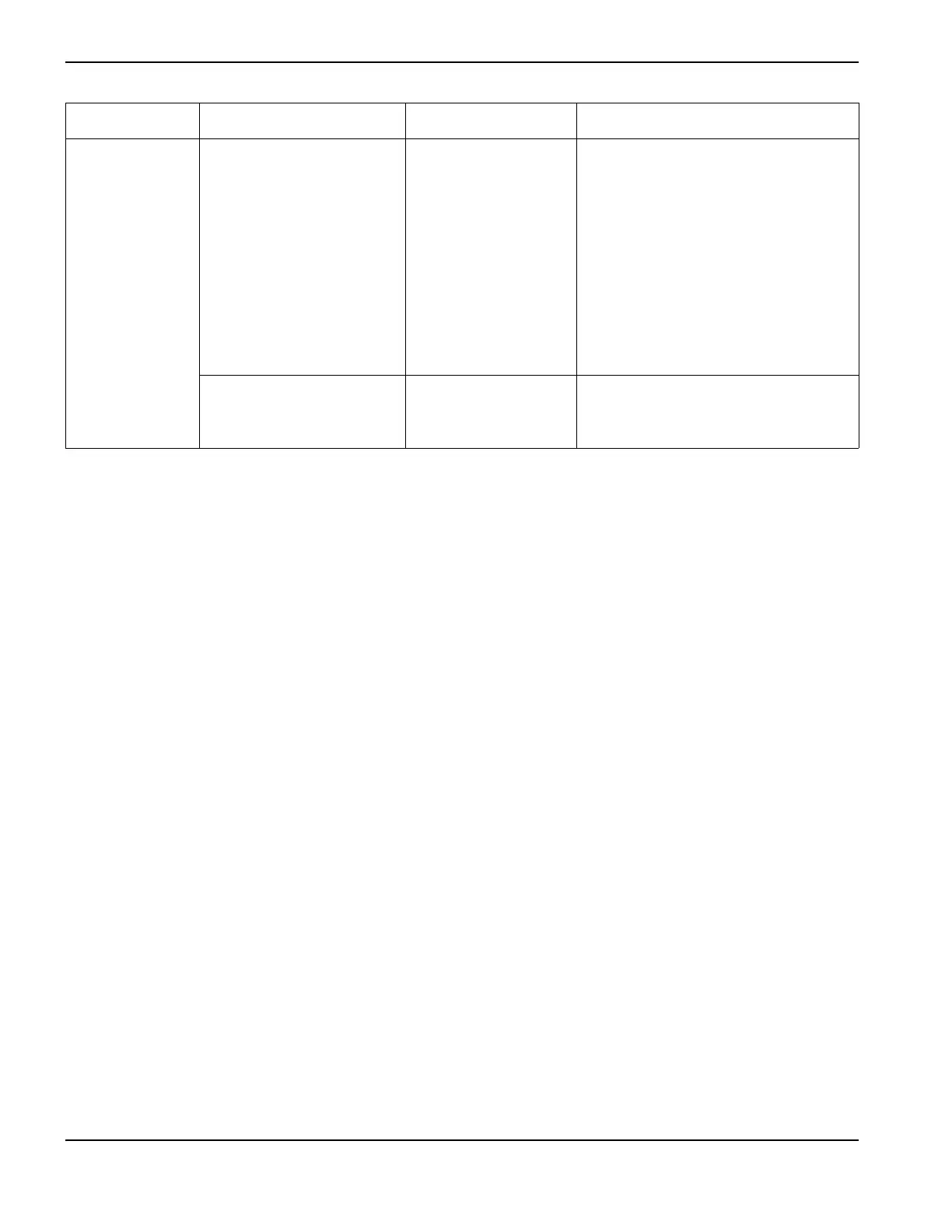

Arc goes out

while cutting or

intermittently will

not fire.

The arc lost contact with the

workpiece.

• The work lead or

work lead connection

may be faulty.

• The material being

cut may require the

use of continuous

pilot arc mode.

• If you are cutting expanded metal,

grate, or any metal with holes, set the

mode switch to continuous pilot arc

mode.

• Check for loose connections at the

ground clamp and at the power

supply.

• Reposition the work lead on the

workpiece.

• Clean the cutting surface to allow a

better connection with the work lead.

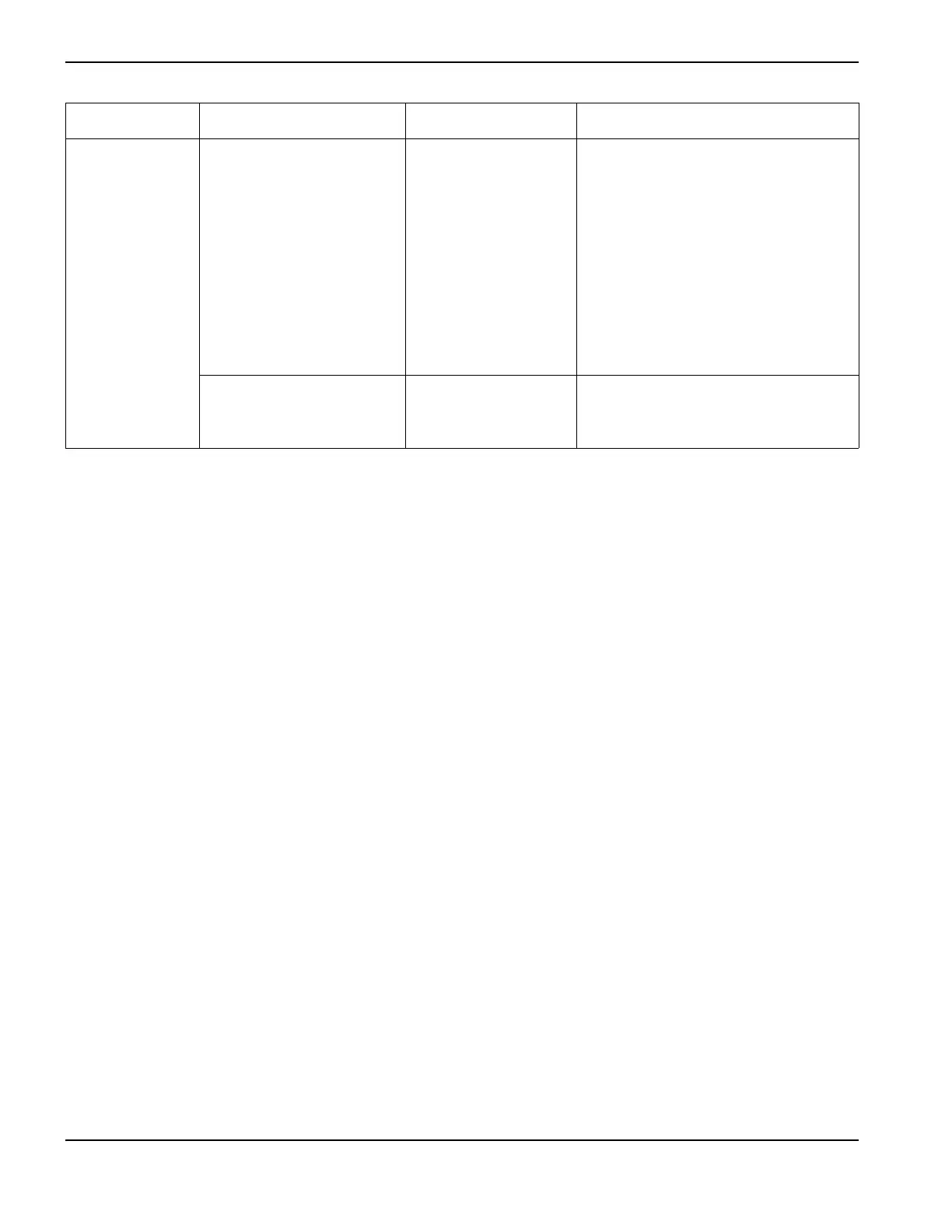

Faulty fan. • The fan could be

overloading the

flyback circuit.

•Perform Test 5 – Flyback circuit (DC

minor voltages) on page 156 and

Test 11 – Fan on page 164.

Problem Meaning Causes Solution

Loading...

Loading...