What to do if Kinco Servo Drives communication drops or has read/write errors?

- AAlisha ChambersNov 2, 2025

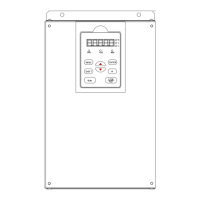

If the Kinco Servo Drives communication drops frequently, experiences read-only or write-only issues, consider these aspects: * Ensure proper termination by setting the dial code of the first and last drives to the ON position to activate the internal 120? terminal resistor, especially with high 485 communication rates and long distances. * Use 24AWG shielded twisted pair cables for the 485 signal, grounding the shielding layers together with a resistance no greater than 1?. * Route communication cables separately from power cables, maintaining a distance of at least 20cm, or use a metal tube for better interference protection. Avoid parallel laying and ensure signal and power lines intersect vertically. * Ensure the motor power cable has a shielded net, connect the motor PE to th...