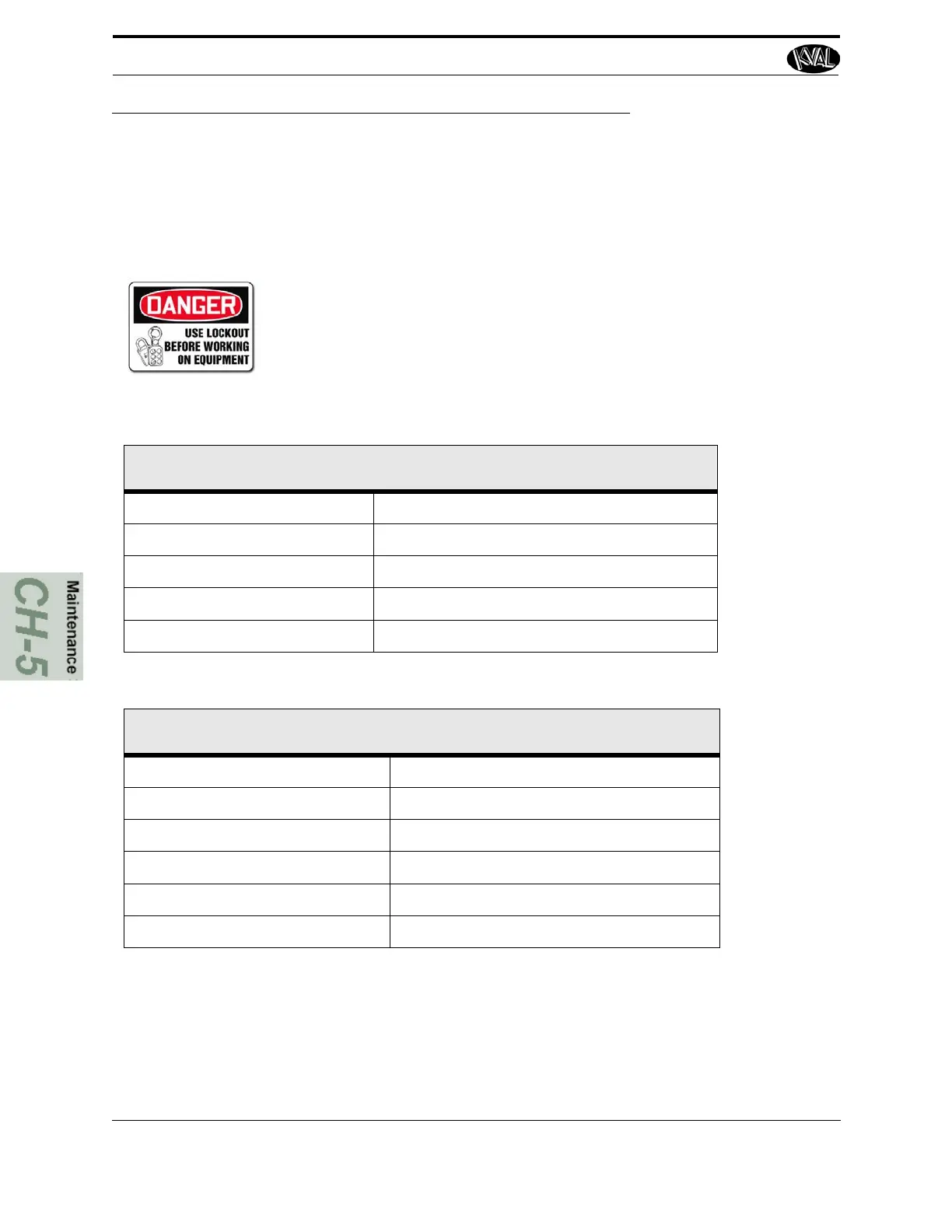

Tool Changing Schedule

KVAL 994-X Operation/Service Manual

5-14

Tool Changing Schedule

Changing and inspecting the tooling on a regular basis keeps the door machining process running

accurately and efficiently. KVAL recommends using the tables below for reference to change or

inspect the machine tooling. Note: Depending on Machine or Option, some of these tools may

vary.

Prior to performing any maintenance, repairs, cleaning or when

clearing jammed debris, you must disconnect, tagout, or lockout the

electrical and air pressure systems. This should be done in accor-

dance with applicable state and/or federal code requirements

Hinge Router and Pre-Drill Tooling

HingeRouterBit

1500cycles

ChiselsInserts

1500cycles

Chip‐OutBlock

10,000‐20,000cycles

9/64”Pre‐DrillBit

10,000‐20,000cycles

1/8”Pre‐DrillBit

10,000‐20,000cycles

Lock Section Tooling

FacePlateRouterBit

2,500cycles

2‐1/8”FaceBoreBit

2,500cycles

2‐1/8”FaceBoreBitInserts

2,500cycles

InsertScoringSpurfor2‐1/8”Bit

2,500cycles

FaceBoreChip‐OutBlock

2,500cycles

1”BoltDrillBit

2,500cycles

Loading...

Loading...