Note: KVAL suggests to follow the steps in the order below.

Step 1 Verify and Adjust the Hinge Carriage

Step 2 Verify and Adjust the Router and Counter Rotate Router Calibration

Step 3 Verify and Adjust the Pre-Drill Calibration

Step 4 Verify and Adjust the Chisels Calibration (Opt. CH)

Check Specifications of the Front Section

3-9

KVAL 994-X Operation/Service Manual

Select the Setup------Setup Hinge (1-4) buttons to display the setup menu. For descriptions of

menus, see “About the Setup Hinges 1-4 Screens” on page 2-45.

Step 1: Hinge Carriage Calibration

Adjusting the X Axis

1. Run the Calibration Routine. See “Run the Calibration Routine” on page 3-6. Use

the H Block as a reference to determine the horizontal center of the calibration slot.

Figure 3- 6 on page 3-10, shows an example of left and right off center locations.

2. Measure the amount of material left between the H-block and the slot on both sides

of the slot (a and b).

3. Calculate the difference between “a “and “b” and then divide by two. See Figure 3-

6 on page 3-10.

4. Next, what way does the slot need to move? To move to the left, enter a positive

number. To move to the right enter a negative number.

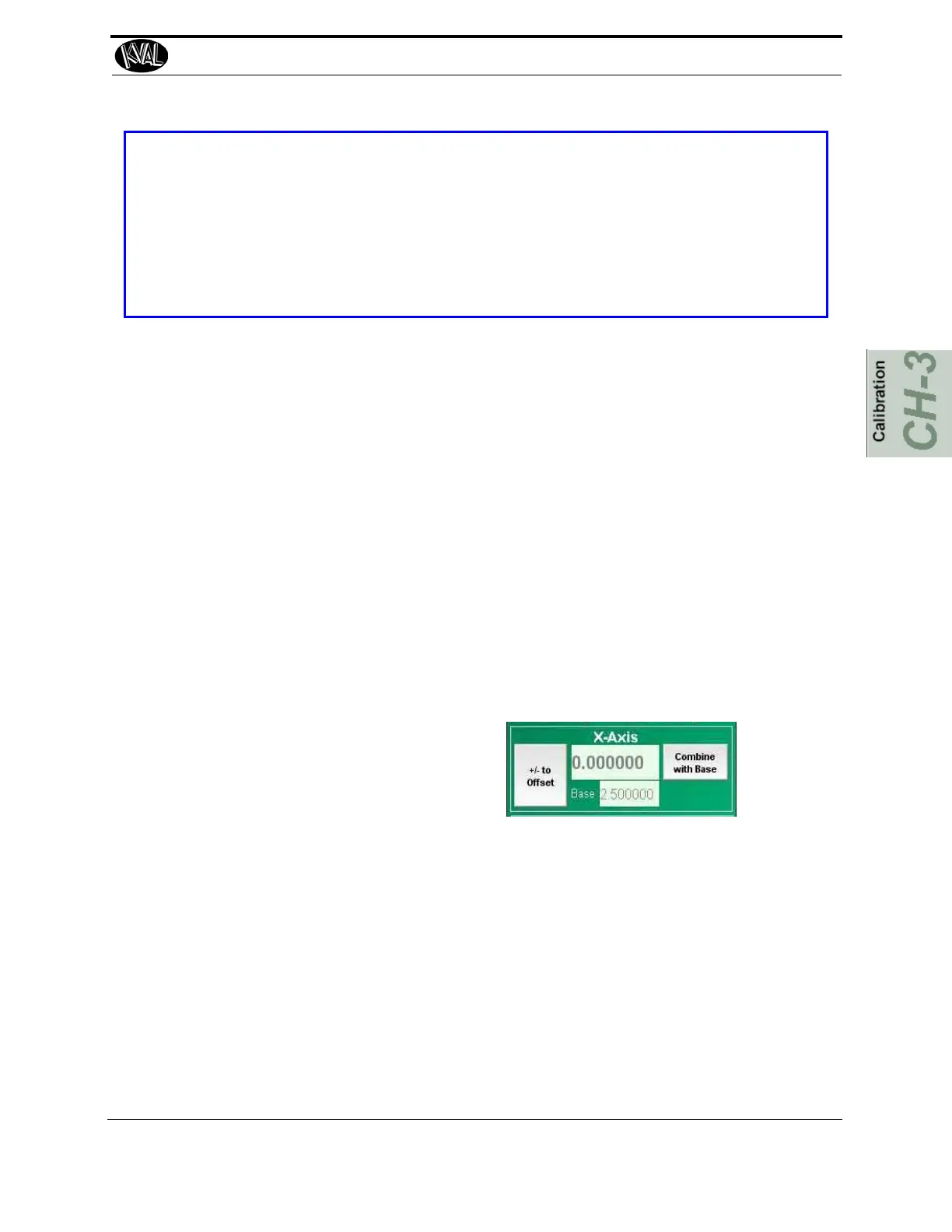

5. Locate the appropriate Menu in the

Setup interface screens

6. If there is a number in the box under X-Axis, select the Combine with Base button to

set a reference.

7. Once this number is added to the base, double select the box that has 0.000. A calcu-

lator will be displayed. Enter the offset in this box.

8. If it needs to go in the negative direction, select the negative symbol.

9. Select the check mark to confirm this number and exit to go back to the Setup

screen.

10. Exit out of the Setup screen and rerun the Calibration test.

11. Re-measure the slot.

12. If slot is not centered, repeat the steps above until the slot is centered.

13. After centering is achieved, select Combine with Base to store the corrections.

Loading...

Loading...