Chapter 4 Wiring

4-15

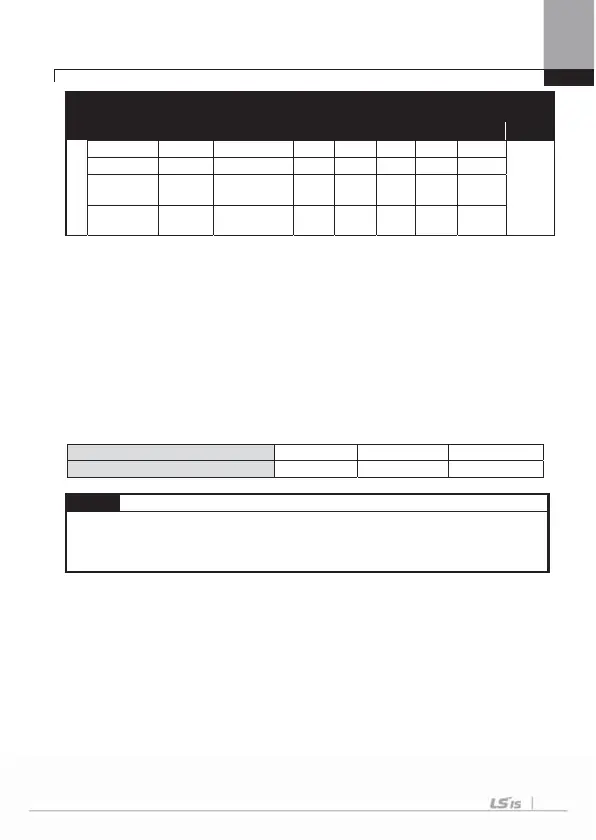

Inverter applied

Terminal

Screw

size

Screw torque

1)

(Kgf·cm)

Cable

Exterior fuse

mm

AWG

R,S,T U,V,W R,S,T U,V,W Current Voltage

220 kW M12 182.4~215.0 250 250 500 500 800A

280 kW M12 182.4~215.0 325 325 650 650 1000A

315 kW M12 182.4~215.0 2x200 2x200

2x40

0

2x400 1200A

375 kW M12 182.4~215.0 2x250 2x250

2x50

0

2x500 1400A

1) : Apply the prescribed torque for the terminal screws. If the screws are loose, it might cause a

failure.

2) : Use 600V 75 copper cable.

The entire cable length should be below 150m. In case of connection of the motor, the entire

length should not exceed 150m because if a motor is connected from a remote location, the

over current protection function might be started by the harmonics caused by the floating

volume increment within the cables or a failure of the device connected to the secondary side

might occur. The entire cable length should be below 150m too when you connect more than

one motor. Do not use a triplex cable in case of distance wiring. (50m when below 3.7KW)

In case of lengthy wiring, Use thick wire in order to reduce line voltage drop and decrease the

carrier frequency or use a micro surge filter.

Line Voltage Drop [V] = (¥3 X wire resistance [mȍ/m]X wire length [m] X Current [A])/1000

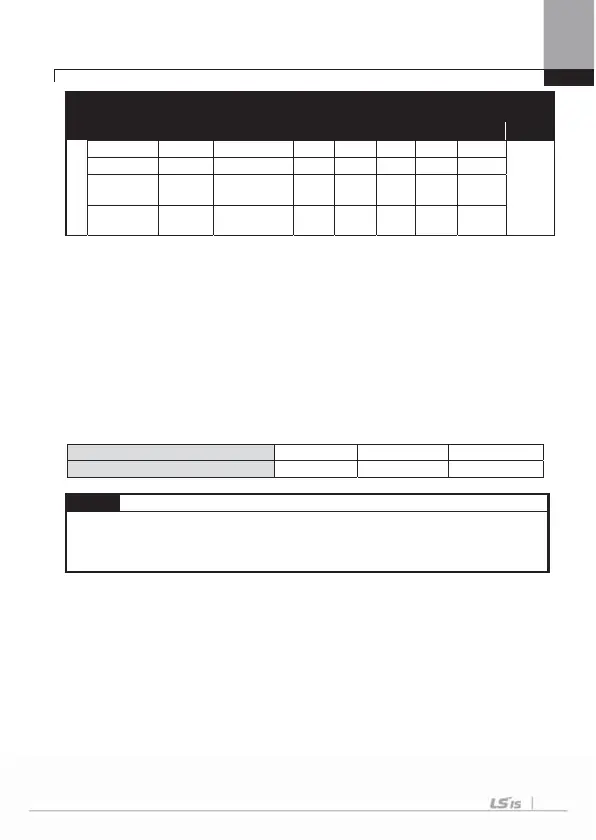

Distance between inverter and motor Up to 50 m Up to 100 m Over 100 m

Permitted carrier frequency Below 15 kHz Below 5 kHz Below 2.5 kHz

Note Short Circuit Rating

Suitable for use on a circuit capable of delivering not more than 5,000 rms Symmetrical

Amperes, 240 or 480 Volts Maximum. When protected by a circuit breaker having an

interrupting rating not less than 100,000 rms symmetrical amperes, Suitable for use on a circuit

capable of delivering not more than 100,000 rms Symmetrical Amperes, 480 Volts Maximum.

Loading...

Loading...