BIT -

K4201 axis X error BIT -

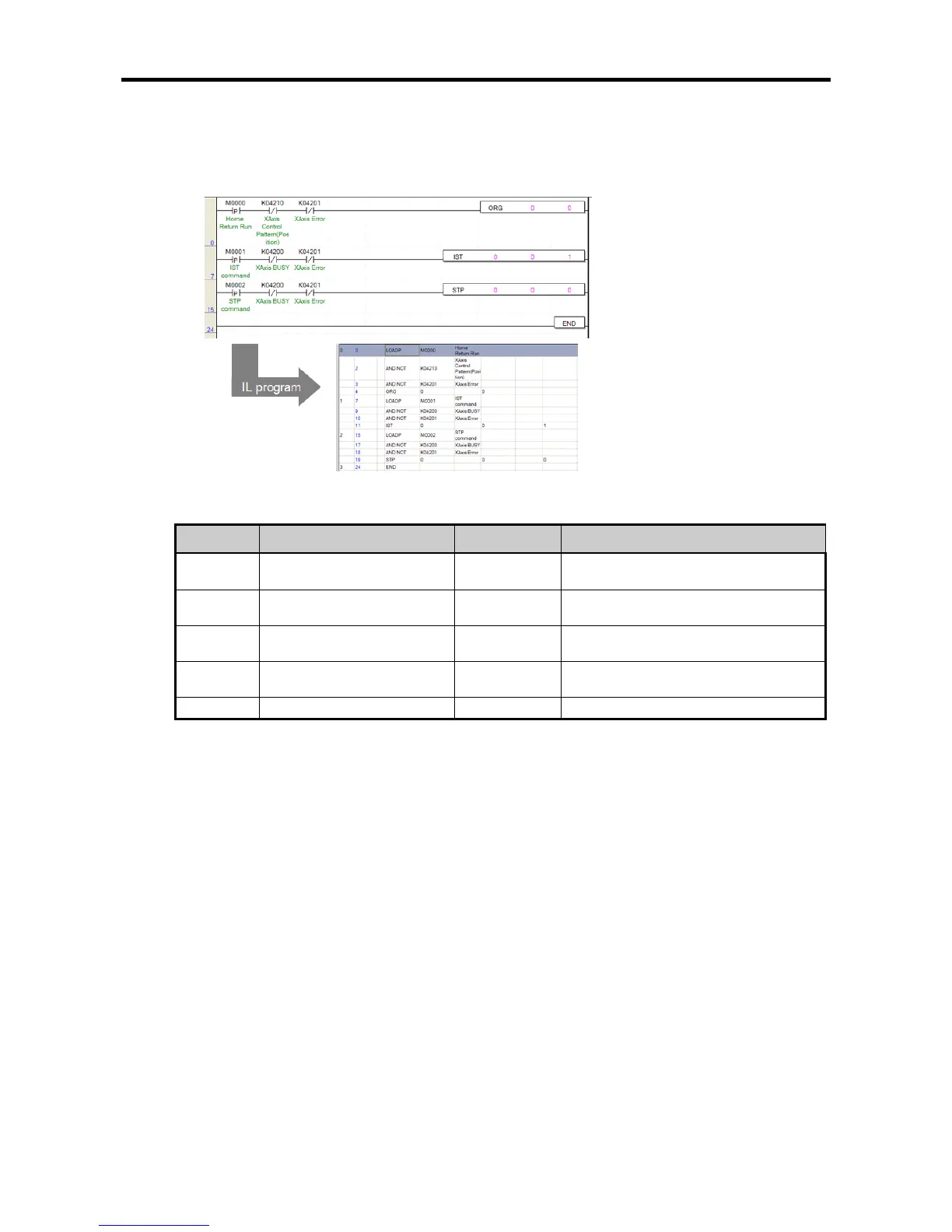

(c) Operation of the Program

• IST instruction is executed when there is the rising edge of M0001, which was used as the indirect

starting instruction signal.

- In the program above, the indirect starting of No. 1 step of axis X is executed.

• If there is the rising edge of M0002, which is the deceleration stop instruction signal during

operation, the deceleration stop instruction is executed according to the setting of STP instruction.

- Since sl (first Operand) and ax(second Operand) are set at 0, the deceleration stop is executed

for axis X of basic unit built-in positioning.

- Since the deceleration time is set at 0, if the STP instruction is executed, it stops right away

without deceleration.

• Note the following in executing the STP instruction.

- If it has been stopped by the deceleration stop instruction, because the positioning operation has

not been finished to the set target position, no positioning completion signal (axis X:K4202, axis

Y:K4302) is generated, and if M code is set, the M code signal does not turn On either.

- In this case, the operation step number maintains the current step.

- If the indirect starting instruction is executed again afterwards, the operation methods differs

according to the coordinates type.

1) Absolute coordinates: The remaining position output which has not been output from the

current operation step is output.

2) Incremental coordinates: Operation is conducted as much as the new target position.

- For example, if the target value of the corresponding step is 20,000 and it has been stopped at

15,000 by the deceleration stop instruction, and if the indirect starting is executed again, in case

of absolute coordinates, operation is done as much as 5,000 and stops at 20,000, and in case of

Incremental coordinates, it newly moves 20,000 and stops at 35,000.

Loading...

Loading...