Chapter 5 Positioning Instructions

5 - 34

5.2.13 Speed Override Instruction

• The speed override instruction (SOR) is for changing the operation speed of the axis during current

positioning operation into the speed set in the instruction. For details, refer to 3.1.10.

(1) Speed Override Instruction (SOR)

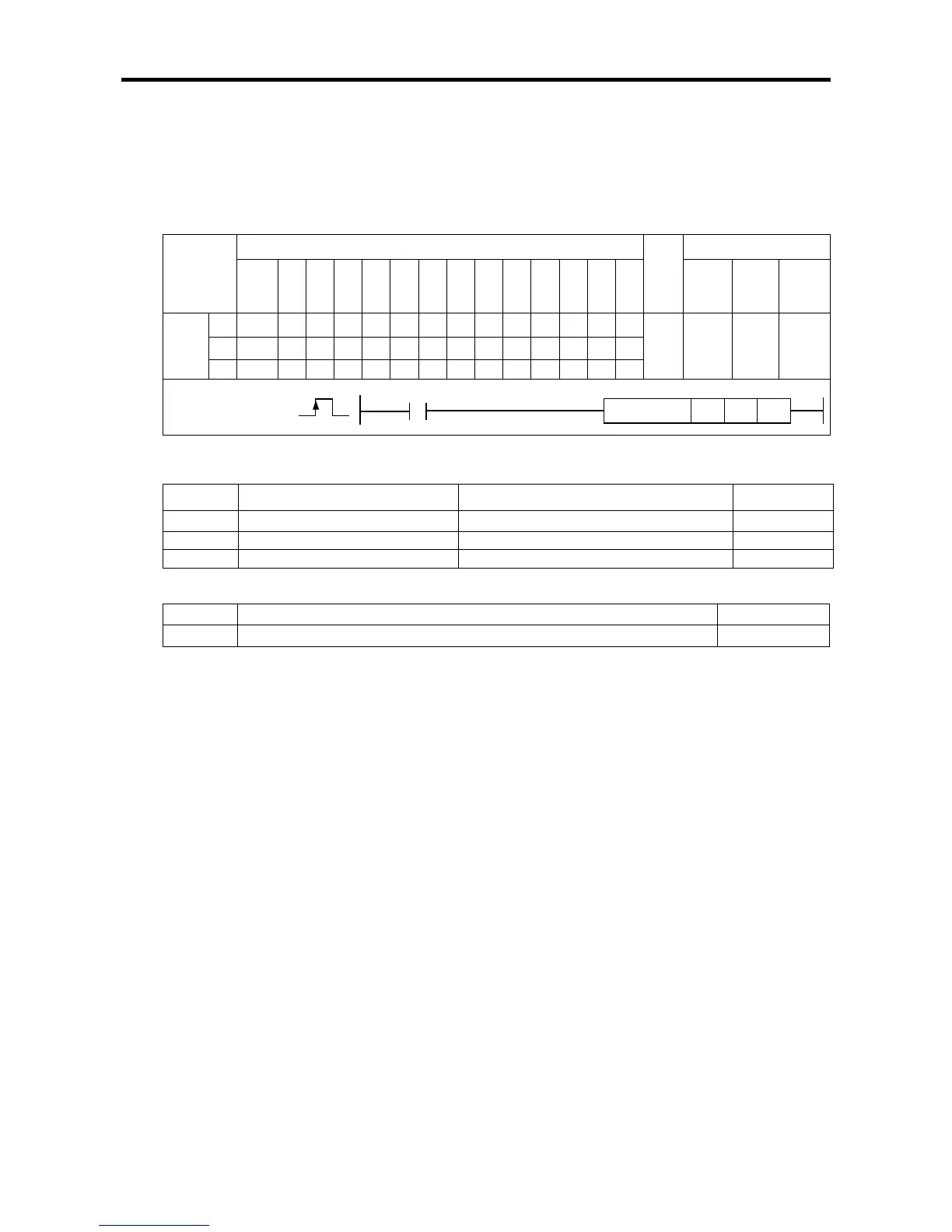

[Area Setting]

Operand

[Flag Set]

Flag Description Device number

Error If the value of ax gets out of the range F110

(a) Function

• This instruction is giving the speed override instruction to XGB built-in positioning.

• This is for changing the operation speed into the speed set in n1 during the operation of the axis

designated as ax at the rising edge of the input condition.

• The speed override instructions available in the acceleration and constant speed sections and if

the speed override is executed during deceleration or dwell, error code 377 is issued and the

currently operating operation step continues.

(b) Error

• If the value designated as ax (instruction axis) is other than 0 and 1, the error flag (F110) is set

and the instruction is not executed.

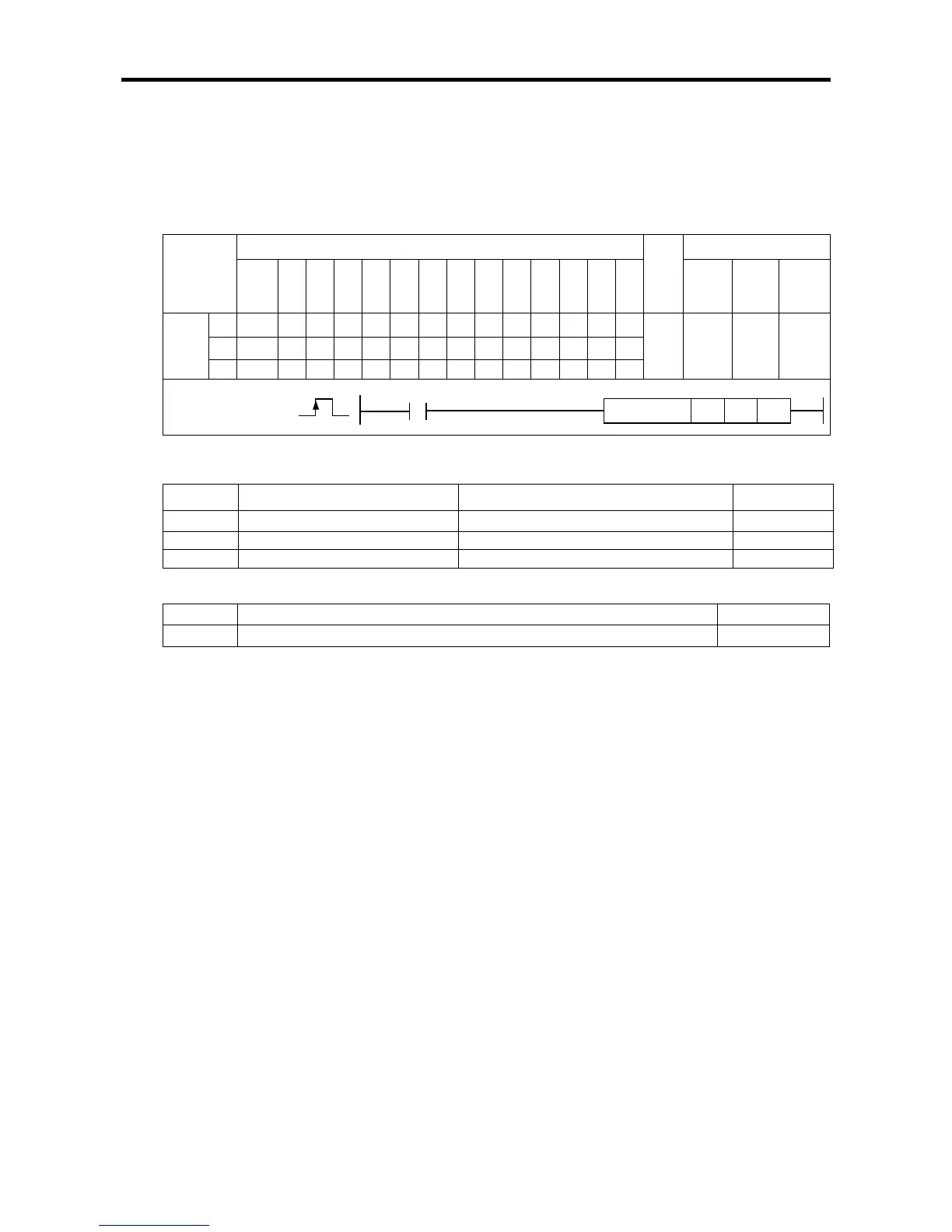

(2) Example of Use of the Instruction

• The speed override instruction is described with the example of the following program.

Instruction

Areas available

Step

Flag

PMK F L T C S Z D.x R.x

con

stan

Loading...

Loading...