Chapter 5 Positioning Instructions

5 - 18

5.2.6 Simultaneous Starting Instruction

• The simultaneous starting instruction (SST instruction) is for simultaneously starting the steps of the

axes set in the instruction. For details, refer to 3.1.7.

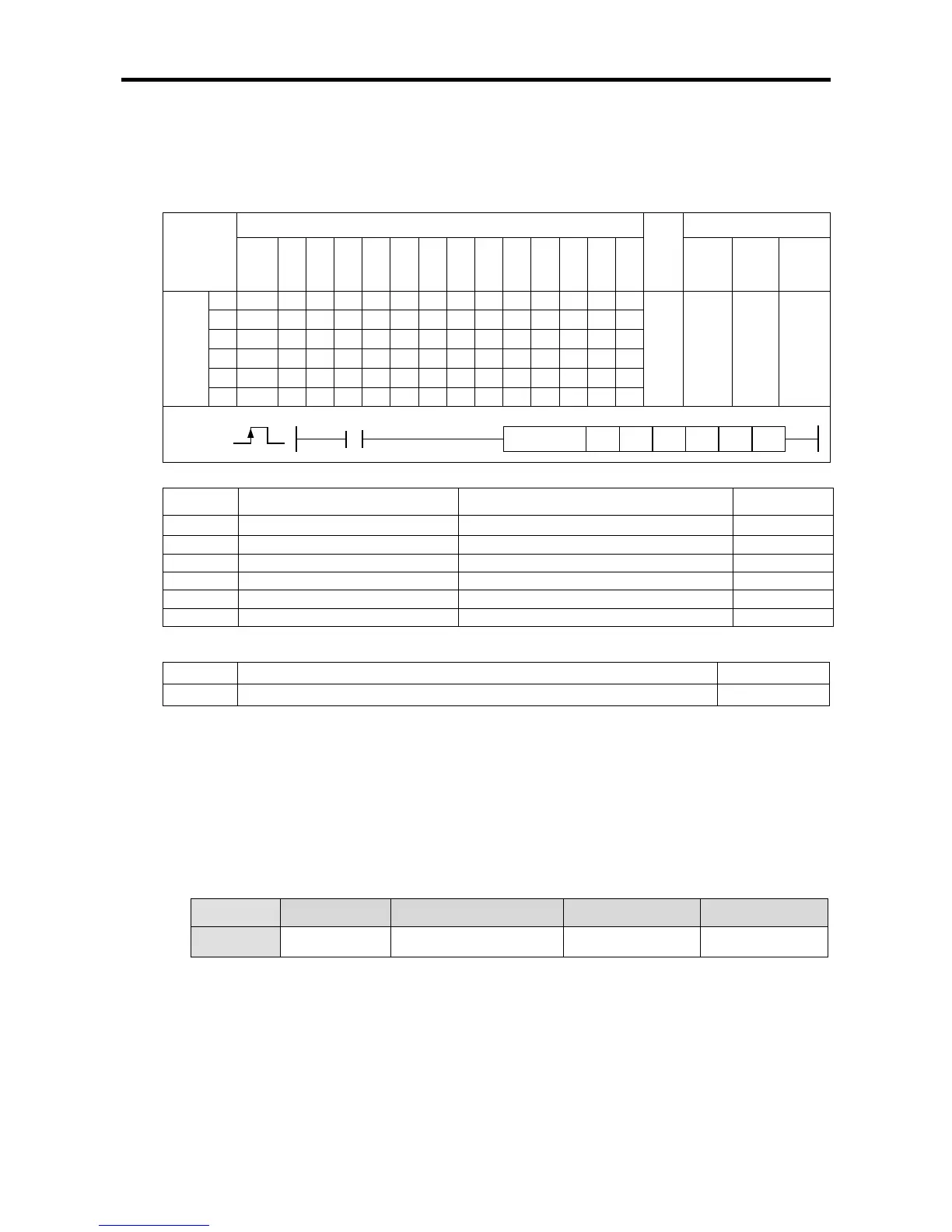

(1) simultaneous starting instruction (SST)

[

[Area Setting]

Operand

[Flag Set]

Flag Description Device number

Error If the value of ax gets out of the range F110

(a) Function

• This function is for giving the simultaneous starting instruction to XGB built-in positioning

simultaneous starting.

• The two axes of XGB positioning are simultaneously started at the rising edge of the input

condition. (For the difference between using the simultaneous starting instruction and starting the

two axes consecutively in the PLC ladder program, refer to 3.1.7.)

• When the instruction is executed, axis X and axis Y simultaneously start by using the operation

data of the step number set in n1 and n2 respectively. XGB built-in positioning does not have axis

Z, so the set value of n3 does not affect the operation.

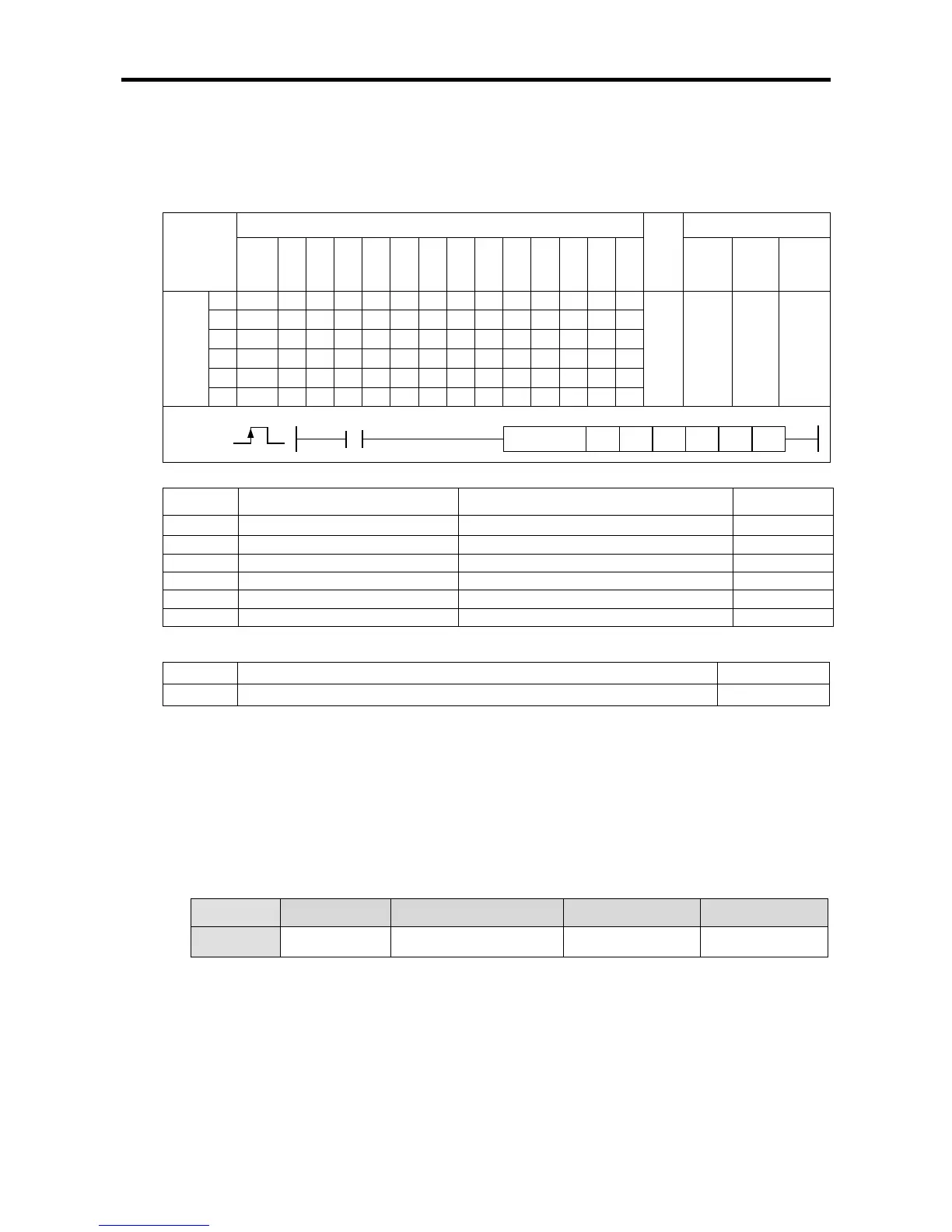

• Axis setting of n4 sets the axis to carry out simultaneous starting by bit as follows.

Bit No. 15 ~ 3 2 1 0

Setting Not used Axis Z (XGB not used) axis Y axis X

- Each bit refers to the axis to start straight interpolation. In the case of XGB built-in positioning,

only axis X and axis Y are available, so n4 should be fixed at 3. Otherwise, error code 296 is

issued and operation does not occur.

(b) Error

• If the value designated as ax (instruction axis) is other than 0 and 1, the error flag (F110) is set

and the instruction is not executed.

• Since this case if an error of execution of the instruction, the error in positioning area K error

flag(axis X:K4201, axis Y: K4301) does not turn On..

• If the set value of the starting step number gets out of the settable range, instruction Error

Flag(F110) is not set, the error flag of positioning area K (axis X:K4201, axis Y: K4301) turns On,

and the operation does not occur.

Instruction

Areas available

Step

Flag

PMK F L T C S Z D.x R.x

con

stan

Loading...

Loading...