Chapter 4 Positioning Check

4- 1

Chapter 4 Positioning Check

This Chapter describes how to test the operation test to check whether the positioning function is well performed

before the XGB positioning function is used.

4.1 The Sequence of Positioning Check

This is for checking whether the XGB positioning operation is normally performed by carrying out normal

and reverse direction jog operation. The sequence is as follows.

(1) Power Off

• Distribution is needed to check the XGB positioning operation.

Before distribution, turn off XGB.

• Be sure to check whether the PWR LED of XGB is off before moving on to the next step.

(2) Input Signal Distribution

• Distribute the input signals needed to check the operation as follows.

• Do not connect the output signal line to the motor driver. If there is a problem with the PLC hardware,

connecting to the motor driver might lead to malfunction or damage to the equipment.

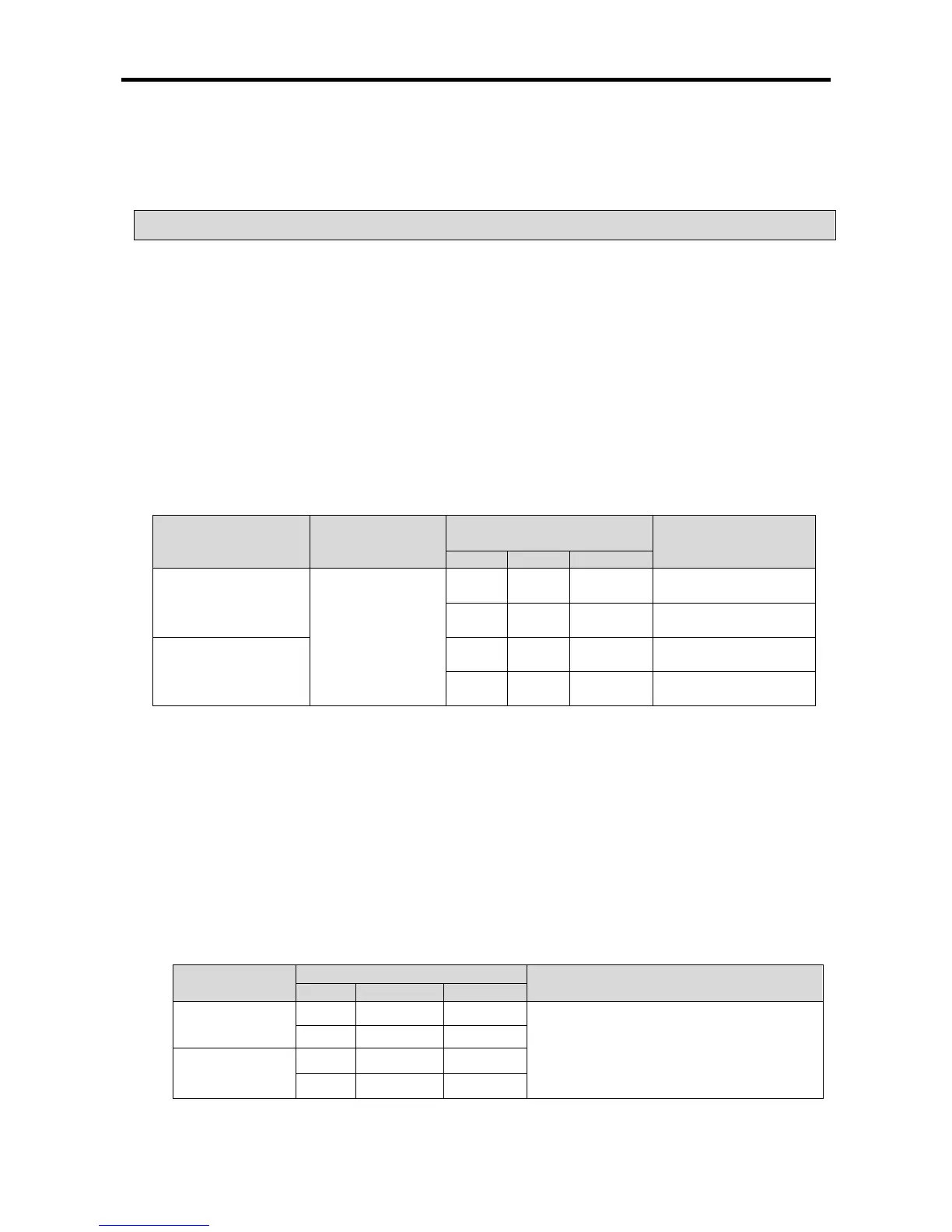

Input Signal

Contact Point

Type

Contact Point No.

Remark

XBC XEC

Jog normal direction

switch

Contact point

normally open (A)

Axis X P0010 %IX0.0.16

Contact point

randomly selected

Axis Y P0011 %IX0.0.17

Contact point

randomly selected

Jog reverse direction

switch

Axis X P0012 %IX0.0.18

Contact point

randomly selected

Axis Y P0013 %IX0.0.19

Contact point

randomly selected

(3) Making the Program for Operation Check

• Make the program for checking the operation by using XG5000. For the details and making of the

program, see ‘4.2 Making of the

Program for Operation Check.’

(4) Power Supply and Program Writing

• If you have finished making the program, supply power to XGB PLC, and use XGB as the parameter

and the program.

(5) Input Contact Point Operation Check

• Before switching the operation mode of the PLC to RUN, check the normal operation of the input

contact point as follows.

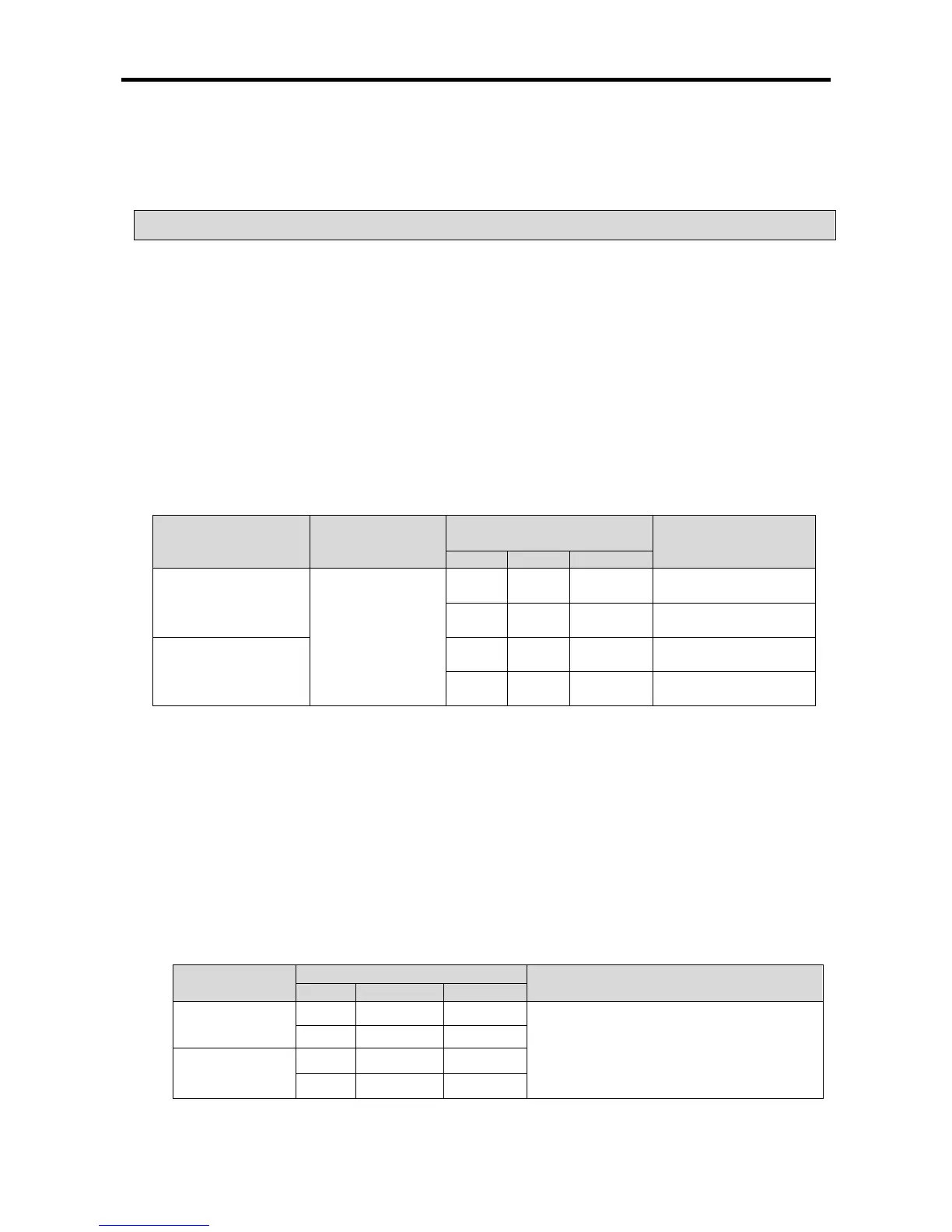

Input Signal

Contact No.

Operation Check

XBC XEC

Jog normal

direction

Axis X P0010 %IX0.0.16

• Check whether the LED of the contact

point turns on while the switch is ON and

the value of the contact point changes into

1 in the device monitor of XG5000.

Axis Y P0011 %IX0.0.17

Jog reverse

direction

Axis X P0012 %IX0.0.18

Axis Y P0013 %IX0.0.19

• If the device doesn’t work as described in the table above, there might be a problem with the LED or

the input hardware, so contact the customer center.

Loading...

Loading...